Question: A shell-and-tube heat exchanger is to be required to decrease the temperature of 190,000lbb/h nitrobenzene from 180F to 110F. Cooling water available at 27C is

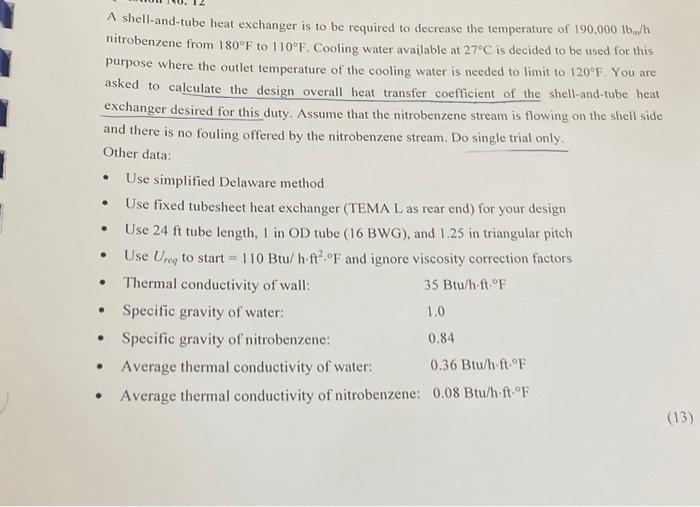

A shell-and-tube heat exchanger is to be required to decrease the temperature of 190,000lbb/h nitrobenzene from 180F to 110F. Cooling water available at 27C is decided to be used for this purpose where the outlet temperature of the cooling water is needed to limit to 120F. You are asked to calculate the design overall heat transfer coefficient of the shell-and-tube heat exchanger desired for this duty. Assume that the nitrobenzene stream is flowing on the shell side and there is no fouling offered by the nitrobenzene stream. Do single trial only. Other data: - Use simplified Delaware method - Use fixed tubesheet heat exchanger (TEMA L as rear end) for your design - Use 24ft tube length, 1 in OD tube (16 BWG), and 1.25 in triangular pitch - Use Ureq to start =110Btu/hft2F and ignore viscosity correction factors - Average thermal conductivity of nitrobenzene: 0.08Btu/ftF

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts