Question: A shell-and-tube heat exchanger with one shell pass and two tube passes is to be designed to condense 3900kg/h of steam at 1atm. The steam

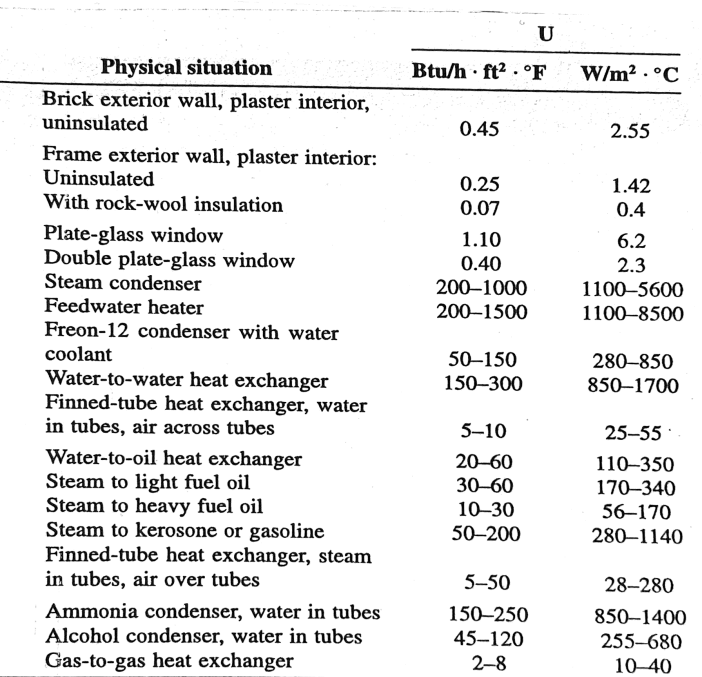

A shell-and-tube heat exchanger with one shell pass and two tube passes is to be designed to condense 3900kg/h of steam at 1atm. The steam may be assumed to enter the shell side as saturated vapor and leave as saturated liquid. Water is employed as the cooling fluid in the tubes with an inlet temperature of 40C. Using approximate values for overall heat transfer coefficients given in the Table, determine a suitable design which specifies a) The number of tubes in each tube pass, b) Outlet water temperature, c) Tube diameter and length in each tube pass, d) The mass flow rate of water, e) Final inside diameter of the shell that may be required, f) Inside and outside heat transfer coefficients. Examine at least two possibilities for overall heat transfer coefficients and evaluate your findings by considering space limitations (tube length must be less than 3m ) and cost of manufacture. As a conclusion, propose the best design parameters. Indicate all your assumptions and origins of data that have been used in your calculations by giving no. of Tables, Appendix, and etc. \begin{tabular}{lcc} & \multicolumn{2}{c}{U} \\ \cline { 2 - 3 } \multicolumn{1}{c}{ Physical situation } & Btu/hft2F & W/m2C \\ Brick exterior wall, plaster interior, & & \\ uninsulated & 0.45 & 2.55 \\ Frame exterior wall, plaster interior: & & \\ Uninsulated & 0.25 & 1.42 \\ With rock-wool insulation & 0.07 & 0.4 \\ Plate-glass window & 1.10 & 6.2 \\ Double plate-glass window & 0.40 & 2.3 \\ Steam condenser & 2001000 & 11005600 \\ Feedwater heater & 2001500 & 11008500 \\ Freon-12 condenser with water & & \\ coolant & 50150 & 280850 \\ Water-to-water heat exchanger & 150300 & 8501700 \\ Finned-tube heat exchanger, water & & \\ in tubes, air across tubes & 510 & 2555 \\ Water-to-oil heat exchanger & 2060 & 110350 \\ Steam to light fuel oil & 3060 & 170340 \\ Steam to heavy fuel oil & 1030 & 56170 \\ Steam to kerosone or gasoline & 50200 & 2801140 \\ Finned-tube heat exchanger, steam & & \\ in tubes, air over tubes & 550 & 28280 \\ Ammonia condenser, water in tubes & 150250 & 8501400 \\ Alcohol condenser, water in tubes & 45120 & 255680 \\ Gas-to-gas heat exchanger & 28 & 1040 \end{tabular} A shell-and-tube heat exchanger with one shell pass and two tube passes is to be designed to condense 3900kg/h of steam at 1atm. The steam may be assumed to enter the shell side as saturated vapor and leave as saturated liquid. Water is employed as the cooling fluid in the tubes with an inlet temperature of 40C. Using approximate values for overall heat transfer coefficients given in the Table, determine a suitable design which specifies a) The number of tubes in each tube pass, b) Outlet water temperature, c) Tube diameter and length in each tube pass, d) The mass flow rate of water, e) Final inside diameter of the shell that may be required, f) Inside and outside heat transfer coefficients. Examine at least two possibilities for overall heat transfer coefficients and evaluate your findings by considering space limitations (tube length must be less than 3m ) and cost of manufacture. As a conclusion, propose the best design parameters. Indicate all your assumptions and origins of data that have been used in your calculations by giving no. of Tables, Appendix, and etc. \begin{tabular}{lcc} & \multicolumn{2}{c}{U} \\ \cline { 2 - 3 } \multicolumn{1}{c}{ Physical situation } & Btu/hft2F & W/m2C \\ Brick exterior wall, plaster interior, & & \\ uninsulated & 0.45 & 2.55 \\ Frame exterior wall, plaster interior: & & \\ Uninsulated & 0.25 & 1.42 \\ With rock-wool insulation & 0.07 & 0.4 \\ Plate-glass window & 1.10 & 6.2 \\ Double plate-glass window & 0.40 & 2.3 \\ Steam condenser & 2001000 & 11005600 \\ Feedwater heater & 2001500 & 11008500 \\ Freon-12 condenser with water & & \\ coolant & 50150 & 280850 \\ Water-to-water heat exchanger & 150300 & 8501700 \\ Finned-tube heat exchanger, water & & \\ in tubes, air across tubes & 510 & 2555 \\ Water-to-oil heat exchanger & 2060 & 110350 \\ Steam to light fuel oil & 3060 & 170340 \\ Steam to heavy fuel oil & 1030 & 56170 \\ Steam to kerosone or gasoline & 50200 & 2801140 \\ Finned-tube heat exchanger, steam & & \\ in tubes, air over tubes & 550 & 28280 \\ Ammonia condenser, water in tubes & 150250 & 8501400 \\ Alcohol condenser, water in tubes & 45120 & 255680 \\ Gas-to-gas heat exchanger & 28 & 1040 \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts