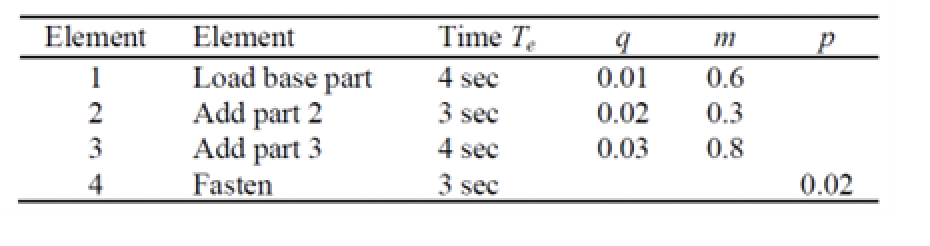

Question: A single - station assembly cell uses an industrial robot to perform a series of assembly operations. The base part and parts 2 and 3

A singlestation assembly cell uses an industrial robot to perform a series of assembly

operations. The base part and parts and are delivered by vibratory bowl feeders that

use selectors to insure that only properly oriented parts are delivered to the robot for

assembly. The robot cell performs the elements in the table below also given are fraction

defect rate q and probability of jam m and, for the last element, the frequency of

downtime incidents p In addition to the times given in the table, the time required to

unload the completed subassembly is sec When a line stop occurs, it takes an average of

min to make repairs and restart the cell. Determine a yield of good product, b

average hourly production rate of good product, and c uptime efficiency for the cell?

Assume the feeders continue to operate and deliver parts into the feed track even when a

jam occurs during assembly and the lowlevel quantity nf is sufficient to eliminate

possibility of a stockout begintabularcllccc

hline Element & Element & Time Te & q & m & p

hline & Load base part & sec & & &

& Add part & sec & & &

& Add part & sec & & &

& Fasten & sec & & &

hline

endtabular

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock