Question: a) What is the average inventory at etching if the batch size is 100 modules? b) What is the approximate utilization of soldering if the

a) What is the average inventory at etching if the batch size is 100 modules?

b) What is the approximate utilization of soldering if the batch size is 100 modules?

c) What is the approximate process capacity in units per hour with a batch size of 100 modules?

d) With a batch size of 100 modules, where is the bottleneck?

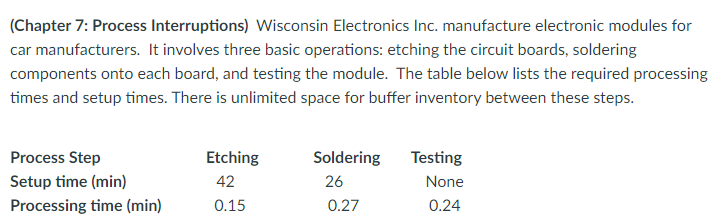

(Chapter 7: Process Interruptions) Wisconsin Electronics Inc. manufacture electronic modules for car manufacturers. It involves three basic operations: etching the circuit boards, soldering components onto each board, and testing the module. The table below lists the required processing times and setup times. There is unlimited space for buffer inventory between these steps. Process Step Setup time (min) Processing time (min) Etching 42 0.15 Soldering 26 0.27 Testing None 0.24Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts