Question: A. Where is this operational systems constraint(s)? (3 marks) B. Calculate the most profitable product mix considering the constraint (6 marks) C. Calculate maximum profit

A. Where is this operational systems constraint(s)? (3 marks)

B. Calculate the most profitable product mix considering the constraint (6 marks)

C. Calculate maximum profit for the system considering it has a constraint (4 marks)

D. Process D-1 can be outsourced to an external supplier that is currently supplying the material for process D-1. In doing so, you will get rid of R50.00 raw material for each unit of products P, Q and R. The supplier will however now charge you R75.00 per unit that he delivers for the outsourced process D-1. You will be able to fully get rid of the fixed costs associated with process D-1. Argue why you should or should not consider the outsourcing. Change in profit should not be the only consideration. Show calculations to support arguments. (8 marks)

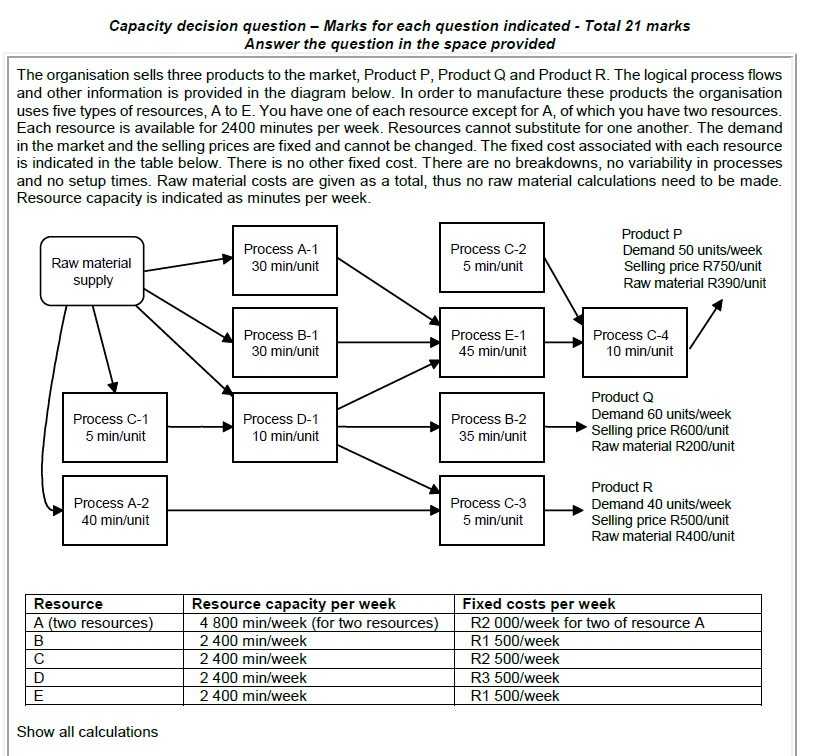

Capacity decision question - Marks for each question indicated - Total 21 marks Answer the question in the space provided The organisation sells three products to the market, Product P, Product Q and Product R. The logical process flows and other information is provided in the diagram below. In order to manufacture these products the organisation uses five types of resources, A to E. You have one of each resource except for A, of which you have two resources. Each resource is available for 2400 minutes per week. Resources cannot substitute for one another. The demand in the market and the selling prices are fixed and cannot be changed. The fixed cost associated with each resource is indicated in the table below. There is no other fixed cost. There are no breakdowns, no variability in processes and no setup times. Raw material costs are given as a total, thus no raw material calculations need to be made. Resource capacity is indicated as minutes per week. Process A-1 30 min/unit Process C-2 5 min/unit Raw material supply Product P Demand 50 units/week Selling price R750/unit Raw material R390/unit Process B-1 30 min/unit Process E-1 45 min/unit Process C-4 10 min/unit Process C-1 5 min/unit Process D-1 10 min/unit Process B-2 35 min/unit Product Q Demand 60 units/week Selling price R600/unit Raw material R200/unit Process A-2 40 min/unit Process C-3 5 min/unit Product R Demand 40 units/week Selling price R500/unit Raw material R400/unit Resource A (two resources) Resource capacity per week 4 800 min/week (for two resources) 2400 min/week 2 400 min/week 2 400 min/week Fixed costs per week R2 000/week for two of resource A R1 500/week R2 500/week R3 500/week R1 500/week D E 2 400 min/week Show all calculations Capacity decision question - Marks for each question indicated - Total 21 marks Answer the question in the space provided The organisation sells three products to the market, Product P, Product Q and Product R. The logical process flows and other information is provided in the diagram below. In order to manufacture these products the organisation uses five types of resources, A to E. You have one of each resource except for A, of which you have two resources. Each resource is available for 2400 minutes per week. Resources cannot substitute for one another. The demand in the market and the selling prices are fixed and cannot be changed. The fixed cost associated with each resource is indicated in the table below. There is no other fixed cost. There are no breakdowns, no variability in processes and no setup times. Raw material costs are given as a total, thus no raw material calculations need to be made. Resource capacity is indicated as minutes per week. Process A-1 30 min/unit Process C-2 5 min/unit Raw material supply Product P Demand 50 units/week Selling price R750/unit Raw material R390/unit Process B-1 30 min/unit Process E-1 45 min/unit Process C-4 10 min/unit Process C-1 5 min/unit Process D-1 10 min/unit Process B-2 35 min/unit Product Q Demand 60 units/week Selling price R600/unit Raw material R200/unit Process A-2 40 min/unit Process C-3 5 min/unit Product R Demand 40 units/week Selling price R500/unit Raw material R400/unit Resource A (two resources) Resource capacity per week 4 800 min/week (for two resources) 2400 min/week 2 400 min/week 2 400 min/week Fixed costs per week R2 000/week for two of resource A R1 500/week R2 500/week R3 500/week R1 500/week D E 2 400 min/week Show all calculationsStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts