Question: A. Which station is the bottle neck? b. Using the traditional method, which bases decisions solely on a product's contribution to profits and overhead, what

A. Which station is the bottle neck?

b. Using the traditional method, which bases decisions solely on a product's contribution to profits and overhead, what is the optimal product mix and what is the overall profitability?

C. Using the bottleneck-based method, what is the optimal product mix and what is the overall profitability

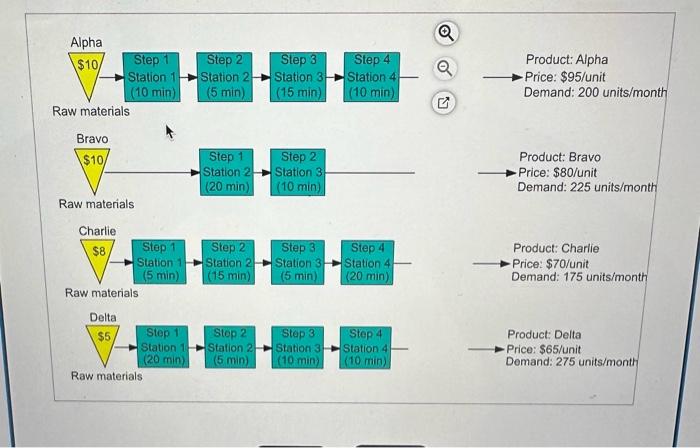

Cooper River Glass Works (CRGW) produces four different models of desk lamps as shown on the flowchart. The operations manager knows that total monthly demand exceeds the capacity available for production. Thus, she is interested in determining the product mix which will maximize profits. Each model's price, routing, processing times, and material cost is provided in the flowchart. Demand next month is estimated to be 200 units of model Alpha, 225 units of model Bravo, 175 units of model Charlie, and 275 units of model Delta. CRGW operates only one 8 hours shift per day and is scheduled to work 20 days next month (no overtime). Further, each station requires a 10% capacity cushion. Alpha Product: Alpha - Price: \$95/unit Demand: 200 units/month Raw materials Product: Bravo -Price: \$80/unit Demand: 225 units/month Raw materials Charlie Product: Charlie $8 (5 min) (15 min) (5 min) (20 min) Price: \$70/unit Demand: 175 units/month Raw materials Product: Delta Price: $65/ unit Demand: 275 units/month Raw materials

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts