Question: according to this case study, i need the solve for the followeing question DISCUSSION QUESTIONS ; Why is business process management (BPM) so important in

according to this case study, i need the solve for the followeing question

DISCUSSION QUESTIONS ; Why is business process management (BPM) so important in a company such as TNT Express? Evaluate their core business process framework and make suggestions for improve ment. 2. How important was the background, in terms of awards and other approaches to the develop ment of business process management in TNT Express? Discuss the resulting leadership and commitment aspects in the company and use this to develop a route map for BPM implemen tation. 3. What role can innovation play in the introduce tion and development of BPM methods used in companies in other industries or organizations in the public sector??

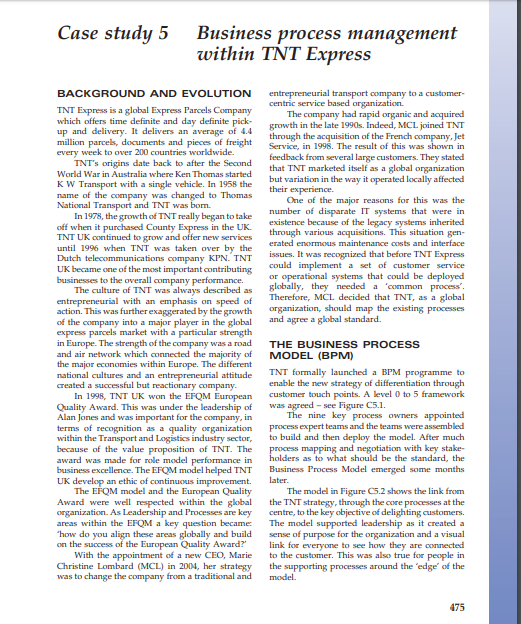

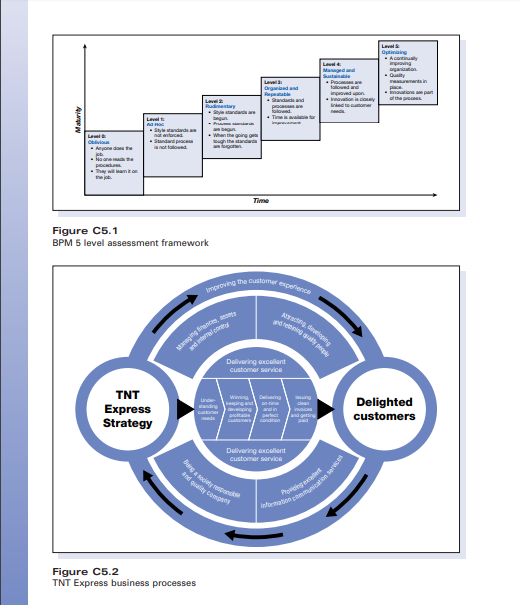

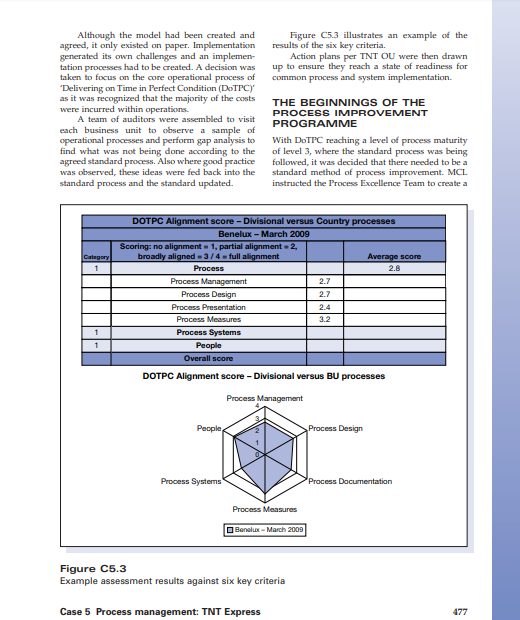

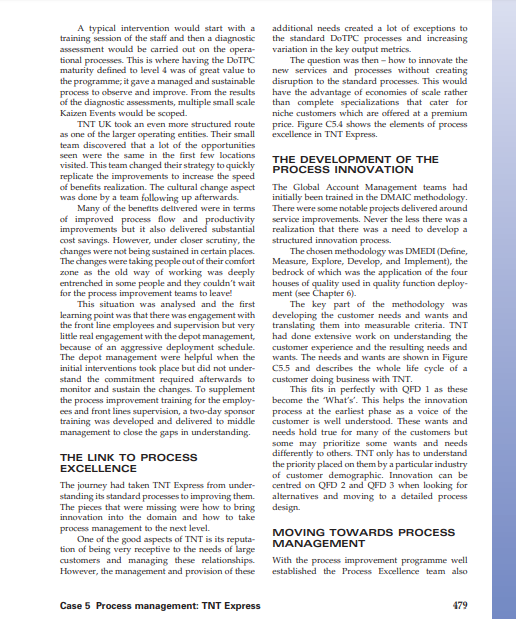

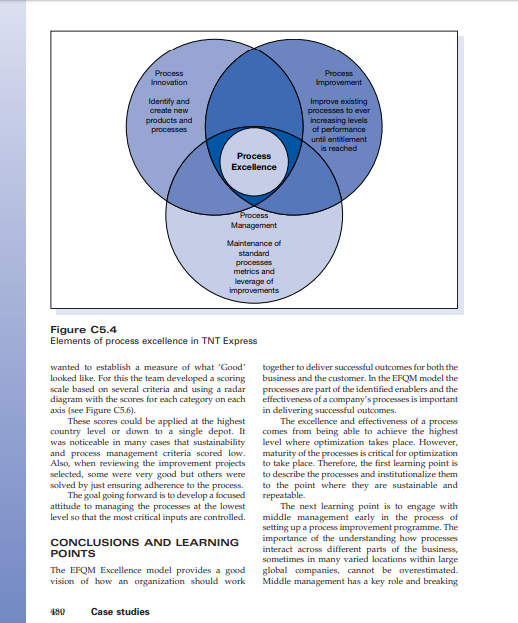

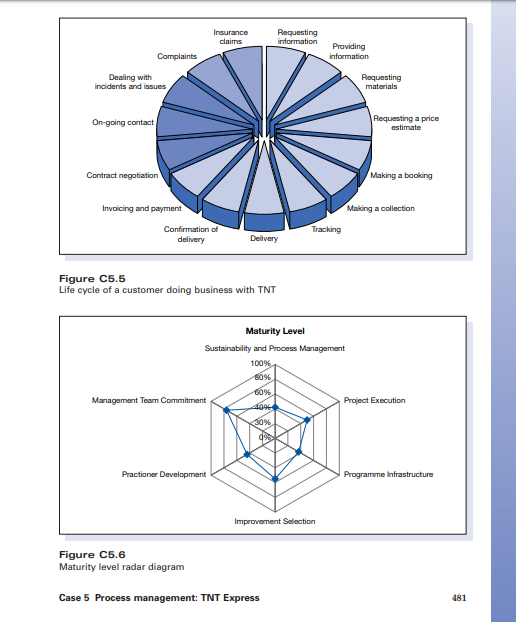

Case study 5 Business process management within TNT Express entrepreneurial transport company to a customer centric service based organization. The company had rapid organic and acquired growth in the late 1990s. Indeed, MCL joined TNT through the acquisition of the French company, Jet Service, in 1998. The result of this was shown in feedback from several large customers. They stated that TNT marketed itself as a global organization but variation in the way it operated locally affected their experience. One of the major reasons for this was the number of disparate IT systems that were in existence because of the legacy systems inherited through various acquisitions. This situation gen- erated enormous maintenance costs and interface issues. It was recognized that before TNT Express could implement a set of customer service or operational systems that could be deployed globally, they needed a common process. Therefore, MCL decided that TNT, as a global organization, should map the existing processes and agree a global standard. BACKGROUND AND EVOLUTION TNT Express is a global Express Parcels Company which offers time definite and day definite pick- up and delivery. It delivers an average of 4.4 million parcels, documents and pieces of freight every week to over 200 countries worldwide. TNT's origins date back to after the Second World War in Australia where Ken Thomas started KW Transport with a single vehicle. In 1958 the name of the company was changed to Thomas National Transport and TNT was bom. In 1978, the growth of TNT really began to take off when it purchased County Express in the UK. TNT UK continued to grow and offer new services until 1996 when TNT was taken over by the Dutch telecommunications company KPN. TNT UK became one of the most important contributing businesses to the overall company performance. The culture of TNT was always described as entrepreneurial with an emphasis on speed of action. This was further exaggerated by the growth of the company into a maior player in the global express parcels market with a particular strength in Europe. The strength of the company was a road and air network which connected the majority of the major economies within Europe. The different national cultures and an entrepreneurial attitude created a successful but reactionary company. In 1998, TNT UK won the EFOM European Quality Award. This was under the leadership of Alan Jones and was important for the company, in terms of recognition as a quality organization within the Transport and Logistics industry sector, because of the value proposition of TNT. The award was made for role model performance in business excellence. The EFQM model helped TNT UK develop an ethic of continuous improvement. The EFQM model and the European Quality Award were well respected within the global organization. As Leadership and Processes are key areas within the EFQM a key question became: "how do you align these areas globally and build on the success of the European Quality Award?' With the appointment of a new CEO, Marie Christine Lombard (MCL) in 2004, her strategy was to change the company from a traditional and THE BUSINESS PROCESS MODEL (BPM) TNT formally launched a BPM programme to enable the new strategy of differentiation through customer touch points. A level 0 to 5 framework was agreed - see Figure C5.1. The nine key process owners appointed process expert teams and the teams were assembled to build and then deploy the model. After much process mapping and negotiation with key stake holders as to what should be the standard, the Business Process Model emerged some months The model in Figure 5.2 shows the link from the TNT strategy, through the core processes at the centre, to the key objective of delighting customers. The model supported leadership as it created a sense of purpose for the organization and a visual link for everyone to see how they are connected to the customer. This was also true for people in the supporting processes around the 'edge of the model. Figure C5.1 BPM 5 level assessment framework in the c ome CE TNT Express Strategy Delighted customers Figure C5.2 TNT Express business processes Figure 05.3 illustrates an example of the results of the six key criteria. Action plans per TNT OU were then drawn up to ensure they reach a state of readiness for common process and system implementation Although the model had been created and agreed, it only existed on paper. Implementation generated its own challenges and an implemen- tation processes had to be created. A decision was taken to focus on the core operational process of Delivering on Time in Perfect Condition (DOTPCY as it was recognized that the majority of the costs were incurred within operations A team of auditors were assembled to visit each business unit to observe a sample of operational processes and perform gap analysis to find what was not being done according to the agreed standard process. Also where good practice was observed, these ideas were fed back into the standard process and the standard updated. THE BEGINNINGS OF THE PROCESS IMPROVEMENT PROGRAMME With DoTPC reaching a level of process maturity of level 3, where the standard process was being followed, it was decided that there needed to be a standard method of process improvement. MCL instructed the Process Excellence Team to create a DOTPC Alignment score - Divisional versus Country processes Benelux - March 2009 Scoring: no alignment - 1. partial alignment -2 broadly aligned 3/4 full alignment Average score Process 2.8 Process Management 2.7 Process Design 2.7 Process Presentation 2.4 Process Measures 3.2 Process Systems People Overall score 1 1 DOTPC Alignment score - Divisional versus BU processes Process Management People SN P rocess Design Process Systems Process Documentation Process Measures Benelux - March 2009 Figure C5.3 Example assessment results against six key criteria Case 5 Process management: TNT Express The Process Excellence team supervised the application of the well-proven DMAIC (Define, Measure, Analyse, Improve, Control) methodology and achieved an improvement of 75 minutes in the last vehicle leaving. The team were astounded how smoothly their operation then ran in the morning Two years later, the biggest sceptic within the training had become one of the biggest advocates of the methodology. Hence, the Process Excellence team generated another success for creating momentum and acceptance of the value of process improvement within the senior and middle management levels. THE GROWTH OF THE PROCESS IMPROVEMENT PROGRAMME process improvement programme'. Two external appointments were made to bring in experienced resources to create the programme from scratch. At that time the financial performance of the company was good and there were good volumes within the network making the necessary contribu- tion to cost recovery. TNT had become used to growth and financial success and, within this environment, gaining any traction for a process improvement programme was extremely difficult. Management at many levels could not see the reason to improve as their thinking was that "We are good enough already.' As is often the case in change management, the programme seemed to need a crisis to gain recognition as to the power of structured process improvement. A crisis did in fact arise when one of TNT's largest customers became dissatisfied with the level of service and threatened to take its business elsewhere. This crisis created the sense of urgency for action required. A team was created to find the root causes of the problem and implement corrective actions. The results of this first large project were far reaching First, it achieved its initial goal of retaining the large customer, the customer's suppliers rating tumed around to the point where TNT could not score any higher in their rating for innovation; the customer's representatives spoke enthusiastically about the method used and the results achieved - indeed the customer was so impressed with the turn around in performance it awarded TNT a substantial amount of new business. Second, the project got the management talking about the results and how to do more of the same. From this, the programme found a champion at a senior level within operations. It was agreed that a pilot should take place in Germany. Training would be provided for a small team from the selected depot and some people from the German head office. Within the training, it was evident that there was resistance to the Process Excellence team visiting Germany to instruct very senior head office operational experts how to improve the operation. When talking about the target for improve ment, there was a lot of negative discussion about all the reasons why it would not work and what had been tried before. The project involved improving the departure times of the vehicles in the morning and a modest target of 5 minutes was set for the last vehicle to leave. The team were sceptical that this would be achieved. From the start, the intention was to train both full and part time staff in the DMAIC methodology and subsequently training materials and pro- grammes were developed. In order to be allowed to attend courses, the Process Excellence team insisted that participants came to the training with a project to apply their learning to This did not always happen, of course, with some people turning up to training at short notice and without any real sense of why they were there. This indicated that there was still a weakness in understanding or real commitment to the programme from some areas of management. The financial crises of the time, in many economies, were beginning to bite deep. TNT IS very much a barometer of economic activity with the volume of trades between countries its life- blood. TNT experienced customers switching to slower but more economical services and the remaining volumes falling dramatically from previous years' high points; it was described as the perfect storm. Hence, there was an even bigger crisis to be managed, with competition between carriers creating downward cost pressure and deterioration of profit margins. This really created the sense of urgency to get things moving on performance improvement within TNT. The Process Excellence team were instructed to increase the speed of deployment throughout six countries within Europe. Starting in the Netherlands a programme was initiated that focused on deployment of process improvement techniques at selected important hubs and depots within the TNT network. 478 Case studies additional needs created a lot of exceptions to the standard DTTC processes and increasing variation in the key output metrics The question was then how to innovate the new services and processes without creating disruption to the standard processes. This would have the advantage of economies of scale rather than complete specializations that cater for niche customers which are offered at a premium price. Figure 5.4 shows the elements of process excellence in TNT Express THE DEVELOPMENT OF THE PROCESS INNOVATION A typical intervention would start with a training session of the staff and then a diagnostic assessment would be carried out on the opera tional processes. This is where having the DoTPC maturity defined to level 4 was of great value to the programme; it gave a managed and sustainable process to observe and improve. From the results of the diagnostic assessments, multiple small scale Kaizen Events would be scoped TNT UK took an even more structured route as one of the larger operating entities. Their small team discovered that a lot of the opportunities seen were the same in the first few locations visited. This team changed their strategy to quickly replicate the improvements to increase the speed of benefits realization. The cultural change aspect was done by a team following up afterwards. Many of the benefits delivered were in terms of improved process flow and productivity improvements but it also delivered substantial cost savings. However, under closer scrutiny, the de d u tiny, the changes were not being sustained in certain places. The changes were taking people out of their comfort zone as the old way of working was deeply entrenched in some people and they couldn't wait for the process improvement teams to leave! This situation was analysed and the first learning point was that there was engagement with the front line employees and supervision but very little real engagement with the depot management, because of an aggressive deployment schedule. The depot management were helpful when the initial interventions took place but did not under stand the commitment required afterwards to monitor and sustain the changes. To supplement the process improwement training for the employ ces and front lines supervision, a two-day sponsor training was developed and delivered to middle management to close the gaps in understanding The Global Account Management teams had initially been trained in the DMAIC methodology There were some notable projects delivered around service improvements. Never the less there was a realization that there was a need to develop a structured innovation process The chosen methodology was DMEDI (Define, Measure, Explore, Develop, and Implement), the bedrock of which was the application of the four houses of quality used in quality function deploy ment (see Chapter 6). The key part of the methodology was developing the customer needs and wants and translating them into measurable criteria TNT had done extensive work on understanding the customer experience and the resulting needs and wants. The needs and wants are shown in Figure C5.5 and describes the whole life cycle of a customer doing business with TNT. This fits in perfectly with OFD 1 as these become the 'What's. This helps the innovation process at the earliest phave as a voice of the customer is well understood. These wants and needs hold true for many of the customers but some may prioritize some wants and needs differently to others. TNT only has to understand the priority placed on them by a particular industry of customer demographic. Innovation can be centred on QFD 2 and OFD 3 when looking for alternatives and moving to a detailed process design THE LINK TO PROCESS EXCELLENCE The journey had taken TNT Express from under standing its standard processes to improving them The pieces that were missing were how to bring innovation into the domain and how to take process management to the next level One of the good aspects of TNT is its reputa- tion of being very receptive to the needs of large customers and managing these relationships However, the management and provision of these MOVING TOWARDS PROCESS MANAGEMENT with the process improvement programme wel established the Process Excellence team also Case 5 Process management: TNT Express Process Innovation Improvement Identify and Create new products and Improve existing processes to ever increasing levels unti entitlement is reached Process Excellence Process Management Maintenance of standard processes metrics and leverage of improvements Figure C5.4 Elements of process excellence in TNT Express wanted to establish a measure of what 'Good looked like. For this the team developed a scoring scale based on several criteria and using a radar diagram with the scores for each category on each axis (see Figure 5.6). These scores could be applied at the highest country level or down to a single depot. It was noticeable in many cases that sustainability and process management criteria scored low Also, when reviewing the improvement projects selected, some were very good but others were solved by just ensuring adherence to the process. The goal going forward is to develop a focused attitude to managing the processes at the lowest level so that the most critical inputs are controlled together to deliver successful outcomes for both the business and the customer. In the EFOM model the processes are part of the identified enables and the effectiveness of a company's processes is important in delivering successful outcomes The excellence and effectiveness of a process comes from being able to achieve the highest level where optimization takes place. However, maturity of the process is critical for optimization to take place. Therefore, the first learning point is to describe the processes and institutionalize them to the point where they are sustainable and repeatable. The next learning point is to engage with middle management early in the process of setting up a process improvement programme. The importance of the understanding how proces interact across different parts of the business sometimes in many varied locations within large global companies, cannot be overestimated Middle management has a key role and breaking CONCLUSIONS AND LEARNING POINTS The EFQM Excellence model provides a good vision of how an organization should work 450 Case studies Insurance claims Requesting ombon Providing information Complaints Dealing with incidents and issues Requesting materials On-going contact Requesting a price estimate Contract negotiation Making a booking Invoicing and payment Making a collection Tracking Confirmation of delivery Delivery Figure C5.5 Life cycle of a customer doing business with TNT Maturity Level Sustainability and Process Management 100% 80% 60% Management Team Commitment Project Execution Practioner Development Programme Infrastructure Improvement Selection Figure C5.6 Maturity level radar diagram Case 5 Process management: TNT Express Operations, TNT Express, in the preparation of this case study. out of the silo' mentality can be difficult. There fore, a programme should include an element of sponsor training to explain their role in process improvement and what sustainable change means Finally, key to process Excellence is process and performance management - a lot of problems can be prevented by good process management. If the front line supervision knows that the inputs to the process and the controls are critical, then the outputs of the process will be delivered with a lot less variation in the customer experience. Good process management and improvement comes from a regular routine of measuring analysing and then taking corrective action on the process. DISCUSSION QUESTIONS . Why is business process management (BPM) so important in a company such as TNT Express? Evaluate their core business process framework and make suggestions for improve ment. 2. How important was the background, in terms of awards and other approaches to the develop ment of business process management in TNT Express? Discuss the resulting leadership and commitment aspects in the company and use this to develop a route map for BPM implemen tation. 3. What role can innovation play in the introduce tion and development of BPM methods used in companies in other industries or organizations ACKNOWLEDGEMENT The author is grateful for the help and information provided by Ian Kendrick, Process Excellence Development Manager, Global Networks and Case study 5 Business process management within TNT Express entrepreneurial transport company to a customer centric service based organization. The company had rapid organic and acquired growth in the late 1990s. Indeed, MCL joined TNT through the acquisition of the French company, Jet Service, in 1998. The result of this was shown in feedback from several large customers. They stated that TNT marketed itself as a global organization but variation in the way it operated locally affected their experience. One of the major reasons for this was the number of disparate IT systems that were in existence because of the legacy systems inherited through various acquisitions. This situation gen- erated enormous maintenance costs and interface issues. It was recognized that before TNT Express could implement a set of customer service or operational systems that could be deployed globally, they needed a common process. Therefore, MCL decided that TNT, as a global organization, should map the existing processes and agree a global standard. BACKGROUND AND EVOLUTION TNT Express is a global Express Parcels Company which offers time definite and day definite pick- up and delivery. It delivers an average of 4.4 million parcels, documents and pieces of freight every week to over 200 countries worldwide. TNT's origins date back to after the Second World War in Australia where Ken Thomas started KW Transport with a single vehicle. In 1958 the name of the company was changed to Thomas National Transport and TNT was bom. In 1978, the growth of TNT really began to take off when it purchased County Express in the UK. TNT UK continued to grow and offer new services until 1996 when TNT was taken over by the Dutch telecommunications company KPN. TNT UK became one of the most important contributing businesses to the overall company performance. The culture of TNT was always described as entrepreneurial with an emphasis on speed of action. This was further exaggerated by the growth of the company into a maior player in the global express parcels market with a particular strength in Europe. The strength of the company was a road and air network which connected the majority of the major economies within Europe. The different national cultures and an entrepreneurial attitude created a successful but reactionary company. In 1998, TNT UK won the EFOM European Quality Award. This was under the leadership of Alan Jones and was important for the company, in terms of recognition as a quality organization within the Transport and Logistics industry sector, because of the value proposition of TNT. The award was made for role model performance in business excellence. The EFQM model helped TNT UK develop an ethic of continuous improvement. The EFQM model and the European Quality Award were well respected within the global organization. As Leadership and Processes are key areas within the EFQM a key question became: "how do you align these areas globally and build on the success of the European Quality Award?' With the appointment of a new CEO, Marie Christine Lombard (MCL) in 2004, her strategy was to change the company from a traditional and THE BUSINESS PROCESS MODEL (BPM) TNT formally launched a BPM programme to enable the new strategy of differentiation through customer touch points. A level 0 to 5 framework was agreed - see Figure C5.1. The nine key process owners appointed process expert teams and the teams were assembled to build and then deploy the model. After much process mapping and negotiation with key stake holders as to what should be the standard, the Business Process Model emerged some months The model in Figure 5.2 shows the link from the TNT strategy, through the core processes at the centre, to the key objective of delighting customers. The model supported leadership as it created a sense of purpose for the organization and a visual link for everyone to see how they are connected to the customer. This was also true for people in the supporting processes around the 'edge of the model. Figure C5.1 BPM 5 level assessment framework in the c ome CE TNT Express Strategy Delighted customers Figure C5.2 TNT Express business processes Figure 05.3 illustrates an example of the results of the six key criteria. Action plans per TNT OU were then drawn up to ensure they reach a state of readiness for common process and system implementation Although the model had been created and agreed, it only existed on paper. Implementation generated its own challenges and an implemen- tation processes had to be created. A decision was taken to focus on the core operational process of Delivering on Time in Perfect Condition (DOTPCY as it was recognized that the majority of the costs were incurred within operations A team of auditors were assembled to visit each business unit to observe a sample of operational processes and perform gap analysis to find what was not being done according to the agreed standard process. Also where good practice was observed, these ideas were fed back into the standard process and the standard updated. THE BEGINNINGS OF THE PROCESS IMPROVEMENT PROGRAMME With DoTPC reaching a level of process maturity of level 3, where the standard process was being followed, it was decided that there needed to be a standard method of process improvement. MCL instructed the Process Excellence Team to create a DOTPC Alignment score - Divisional versus Country processes Benelux - March 2009 Scoring: no alignment - 1. partial alignment -2 broadly aligned 3/4 full alignment Average score Process 2.8 Process Management 2.7 Process Design 2.7 Process Presentation 2.4 Process Measures 3.2 Process Systems People Overall score 1 1 DOTPC Alignment score - Divisional versus BU processes Process Management People SN P rocess Design Process Systems Process Documentation Process Measures Benelux - March 2009 Figure C5.3 Example assessment results against six key criteria Case 5 Process management: TNT Express The Process Excellence team supervised the application of the well-proven DMAIC (Define, Measure, Analyse, Improve, Control) methodology and achieved an improvement of 75 minutes in the last vehicle leaving. The team were astounded how smoothly their operation then ran in the morning Two years later, the biggest sceptic within the training had become one of the biggest advocates of the methodology. Hence, the Process Excellence team generated another success for creating momentum and acceptance of the value of process improvement within the senior and middle management levels. THE GROWTH OF THE PROCESS IMPROVEMENT PROGRAMME process improvement programme'. Two external appointments were made to bring in experienced resources to create the programme from scratch. At that time the financial performance of the company was good and there were good volumes within the network making the necessary contribu- tion to cost recovery. TNT had become used to growth and financial success and, within this environment, gaining any traction for a process improvement programme was extremely difficult. Management at many levels could not see the reason to improve as their thinking was that "We are good enough already.' As is often the case in change management, the programme seemed to need a crisis to gain recognition as to the power of structured process improvement. A crisis did in fact arise when one of TNT's largest customers became dissatisfied with the level of service and threatened to take its business elsewhere. This crisis created the sense of urgency for action required. A team was created to find the root causes of the problem and implement corrective actions. The results of this first large project were far reaching First, it achieved its initial goal of retaining the large customer, the customer's suppliers rating tumed around to the point where TNT could not score any higher in their rating for innovation; the customer's representatives spoke enthusiastically about the method used and the results achieved - indeed the customer was so impressed with the turn around in performance it awarded TNT a substantial amount of new business. Second, the project got the management talking about the results and how to do more of the same. From this, the programme found a champion at a senior level within operations. It was agreed that a pilot should take place in Germany. Training would be provided for a small team from the selected depot and some people from the German head office. Within the training, it was evident that there was resistance to the Process Excellence team visiting Germany to instruct very senior head office operational experts how to improve the operation. When talking about the target for improve ment, there was a lot of negative discussion about all the reasons why it would not work and what had been tried before. The project involved improving the departure times of the vehicles in the morning and a modest target of 5 minutes was set for the last vehicle to leave. The team were sceptical that this would be achieved. From the start, the intention was to train both full and part time staff in the DMAIC methodology and subsequently training materials and pro- grammes were developed. In order to be allowed to attend courses, the Process Excellence team insisted that participants came to the training with a project to apply their learning to This did not always happen, of course, with some people turning up to training at short notice and without any real sense of why they were there. This indicated that there was still a weakness in understanding or real commitment to the programme from some areas of management. The financial crises of the time, in many economies, were beginning to bite deep. TNT IS very much a barometer of economic activity with the volume of trades between countries its life- blood. TNT experienced customers switching to slower but more economical services and the remaining volumes falling dramatically from previous years' high points; it was described as the perfect storm. Hence, there was an even bigger crisis to be managed, with competition between carriers creating downward cost pressure and deterioration of profit margins. This really created the sense of urgency to get things moving on performance improvement within TNT. The Process Excellence team were instructed to increase the speed of deployment throughout six countries within Europe. Starting in the Netherlands a programme was initiated that focused on deployment of process improvement techniques at selected important hubs and depots within the TNT network. 478 Case studies additional needs created a lot of exceptions to the standard DTTC processes and increasing variation in the key output metrics The question was then how to innovate the new services and processes without creating disruption to the standard processes. This would have the advantage of economies of scale rather than complete specializations that cater for niche customers which are offered at a premium price. Figure 5.4 shows the elements of process excellence in TNT Express THE DEVELOPMENT OF THE PROCESS INNOVATION A typical intervention would start with a training session of the staff and then a diagnostic assessment would be carried out on the opera tional processes. This is where having the DoTPC maturity defined to level 4 was of great value to the programme; it gave a managed and sustainable process to observe and improve. From the results of the diagnostic assessments, multiple small scale Kaizen Events would be scoped TNT UK took an even more structured route as one of the larger operating entities. Their small team discovered that a lot of the opportunities seen were the same in the first few locations visited. This team changed their strategy to quickly replicate the improvements to increase the speed of benefits realization. The cultural change aspect was done by a team following up afterwards. Many of the benefits delivered were in terms of improved process flow and productivity improvements but it also delivered substantial cost savings. However, under closer scrutiny, the de d u tiny, the changes were not being sustained in certain places. The changes were taking people out of their comfort zone as the old way of working was deeply entrenched in some people and they couldn't wait for the process improvement teams to leave! This situation was analysed and the first learning point was that there was engagement with the front line employees and supervision but very little real engagement with the depot management, because of an aggressive deployment schedule. The depot management were helpful when the initial interventions took place but did not under stand the commitment required afterwards to monitor and sustain the changes. To supplement the process improwement training for the employ ces and front lines supervision, a two-day sponsor training was developed and delivered to middle management to close the gaps in understanding The Global Account Management teams had initially been trained in the DMAIC methodology There were some notable projects delivered around service improvements. Never the less there was a realization that there was a need to develop a structured innovation process The chosen methodology was DMEDI (Define, Measure, Explore, Develop, and Implement), the bedrock of which was the application of the four houses of quality used in quality function deploy ment (see Chapter 6). The key part of the methodology was developing the customer needs and wants and translating them into measurable criteria TNT had done extensive work on understanding the customer experience and the resulting needs and wants. The needs and wants are shown in Figure C5.5 and describes the whole life cycle of a customer doing business with TNT. This fits in perfectly with OFD 1 as these become the 'What's. This helps the innovation process at the earliest phave as a voice of the customer is well understood. These wants and needs hold true for many of the customers but some may prioritize some wants and needs differently to others. TNT only has to understand the priority placed on them by a particular industry of customer demographic. Innovation can be centred on QFD 2 and OFD 3 when looking for alternatives and moving to a detailed process design THE LINK TO PROCESS EXCELLENCE The journey had taken TNT Express from under standing its standard processes to improving them The pieces that were missing were how to bring innovation into the domain and how to take process management to the next level One of the good aspects of TNT is its reputa- tion of being very receptive to the needs of large customers and managing these relationships However, the management and provision of these MOVING TOWARDS PROCESS MANAGEMENT with the process improvement programme wel established the Process Excellence team also Case 5 Process management: TNT Express Process Innovation Improvement Identify and Create new products and Improve existing processes to ever increasing levels unti entitlement is reached Process Excellence Process Management Maintenance of standard processes metrics and leverage of improvements Figure C5.4 Elements of process excellence in TNT Express wanted to establish a measure of what 'Good looked like. For this the team developed a scoring scale based on several criteria and using a radar diagram with the scores for each category on each axis (see Figure 5.6). These scores could be applied at the highest country level or down to a single depot. It was noticeable in many cases that sustainability and process management criteria scored low Also, when reviewing the improvement projects selected, some were very good but others were solved by just ensuring adherence to the process. The goal going forward is to develop a focused attitude to managing the processes at the lowest level so that the most critical inputs are controlled together to deliver successful outcomes for both the business and the customer. In the EFOM model the processes are part of the identified enables and the effectiveness of a company's processes is important in delivering successful outcomes The excellence and effectiveness of a process comes from being able to achieve the highest level where optimization takes place. However, maturity of the process is critical for optimization to take place. Therefore, the first learning point is to describe the processes and institutionalize them to the point where they are sustainable and repeatable. The next learning point is to engage with middle management early in the process of setting up a process improvement programme. The importance of the understanding how proces interact across different parts of the business sometimes in many varied locations within large global companies, cannot be overestimated Middle management has a key role and breaking CONCLUSIONS AND LEARNING POINTS The EFQM Excellence model provides a good vision of how an organization should work 450 Case studies Insurance claims Requesting ombon Providing information Complaints Dealing with incidents and issues Requesting materials On-going contact Requesting a price estimate Contract negotiation Making a booking Invoicing and payment Making a collection Tracking Confirmation of delivery Delivery Figure C5.5 Life cycle of a customer doing business with TNT Maturity Level Sustainability and Process Management 100% 80% 60% Management Team Commitment Project Execution Practioner Development Programme Infrastructure Improvement Selection Figure C5.6 Maturity level radar diagram Case 5 Process management: TNT Express Operations, TNT Express, in the preparation of this case study. out of the silo' mentality can be difficult. There fore, a programme should include an element of sponsor training to explain their role in process improvement and what sustainable change means Finally, key to process Excellence is process and performance management - a lot of problems can be prevented by good process management. If the front line supervision knows that the inputs to the process and the controls are critical, then the outputs of the process will be delivered with a lot less variation in the customer experience. Good process management and improvement comes from a regular routine of measuring analysing and then taking corrective action on the process. DISCUSSION QUESTIONS . Why is business process management (BPM) so important in a company such as TNT Express? Evaluate their core business process framework and make suggestions for improve ment. 2. How important was the background, in terms of awards and other approaches to the develop ment of business process management in TNT Express? Discuss the resulting leadership and commitment aspects in the company and use this to develop a route map for BPM implemen tation. 3. What role can innovation play in the introduce tion and development of BPM methods used in companies in other industries or organizations ACKNOWLEDGEMENT The author is grateful for the help and information provided by Ian Kendrick, Process Excellence Development Manager, Global Networks andStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts