Question: Aero Maintenance is a small aircraft engine maintenance facility located in Wichita, Kansas. Its new administrator, Ann Daniel, decides to improve material flow in

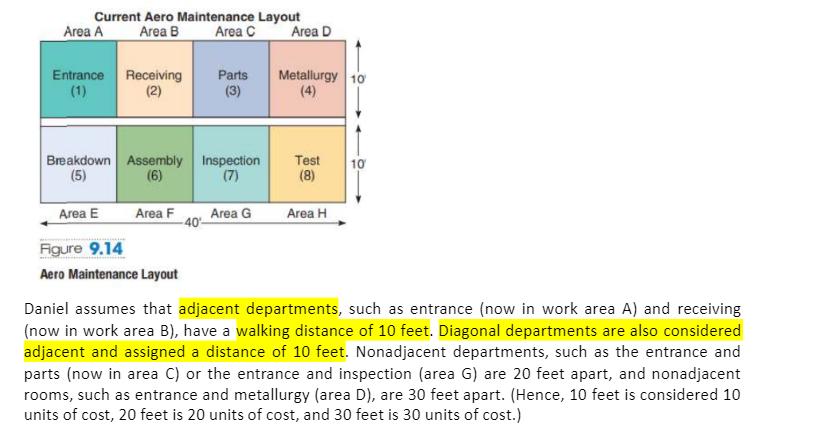

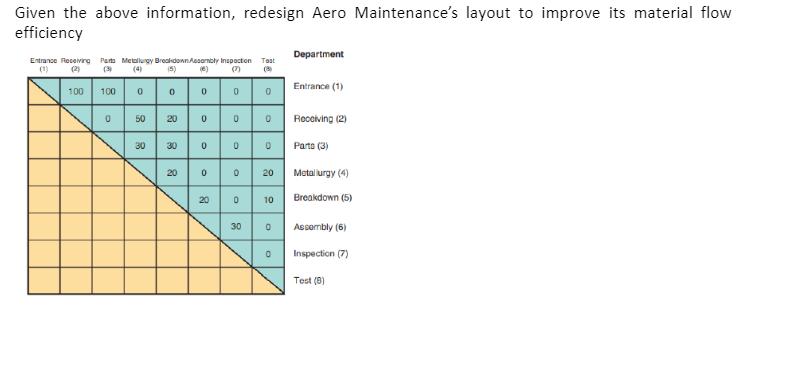

Aero Maintenance is a small aircraft engine maintenance facility located in Wichita, Kansas. Its new administrator, Ann Daniel, decides to improve material flow in the facility, using the process layout method she studied at Wichita State University. The current layout of Aero Maintenance's eight departments is shown in Figure 9.14. The only physical restriction perceived by Daniel is the need to keep the entrance in its current location. All other departments can be moved to a different work area (each 10 feet square) if layout analysis indicates a move would be beneficial. First, Daniel analyzes records to determine the number of material movements among departments in an average month. These data are shown in Figure 9.15. Her objective, Daniel decides, is to lay out the departments so as to minimize the total movement (distance traveled) of material in the facility. She writes her objective as: Current Aero Maintenance Layout Area B Area C Area A Entrance (1) Breakdown (5) Area E Receiving (2) Assembly Inspection (6) Area F Figure 9.14 Aero Maintenance Layout Parts (3) -40- Area G Area D Metallurgy 10 (4) Test 10 (8) Area H Daniel assumes that adjacent departments, such as entrance (now in work area A) and receiving (now in work area B), have a walking distance of 10 feet. Diagonal departments are also considered adjacent and assigned a distance of 10 feet. Nonadjacent departments, such as the entrance and parts (now in area C) or the entrance and inspection (area G) are 20 feet apart, and nonadjacent rooms, such as entrance and metallurgy (area D), are 30 feet apart. (Hence, 10 feet is considered 10 units of cost, 20 feet is 20 units of cost, and 30 feet is 30 units of cost.) Given the above information, redesign Aero Maintenance's layout to improve its material flow efficiency Entrance Receiving Parts Metallurgy Breakdown Assembly Inspection Test (1) (2) (3) (4) (5) (6) M 100 0000 100 0 50 30 20 30 20 0 0 0 20 00 0 0 0 30 0 20 10 0 0 Department Entrance (1) Receiving (2) Parts (3) Metallurgy (4) Breakdown (5) Assembly (6) Inspection (7) Test (8)

Step by Step Solution

3.50 Rating (157 Votes )

There are 3 Steps involved in it

Current layout Total movement 100 x 10 100 x 20 50 x 20 1 to 2 1 to 3 2 to 4 ... View full answer

Get step-by-step solutions from verified subject matter experts