Question: Aggregate operational plan specifies the optimal combination of Select one: a. Production Rate, Review Time, Inventory on Hand b. Production Rate, Workforce Level, Inventory on

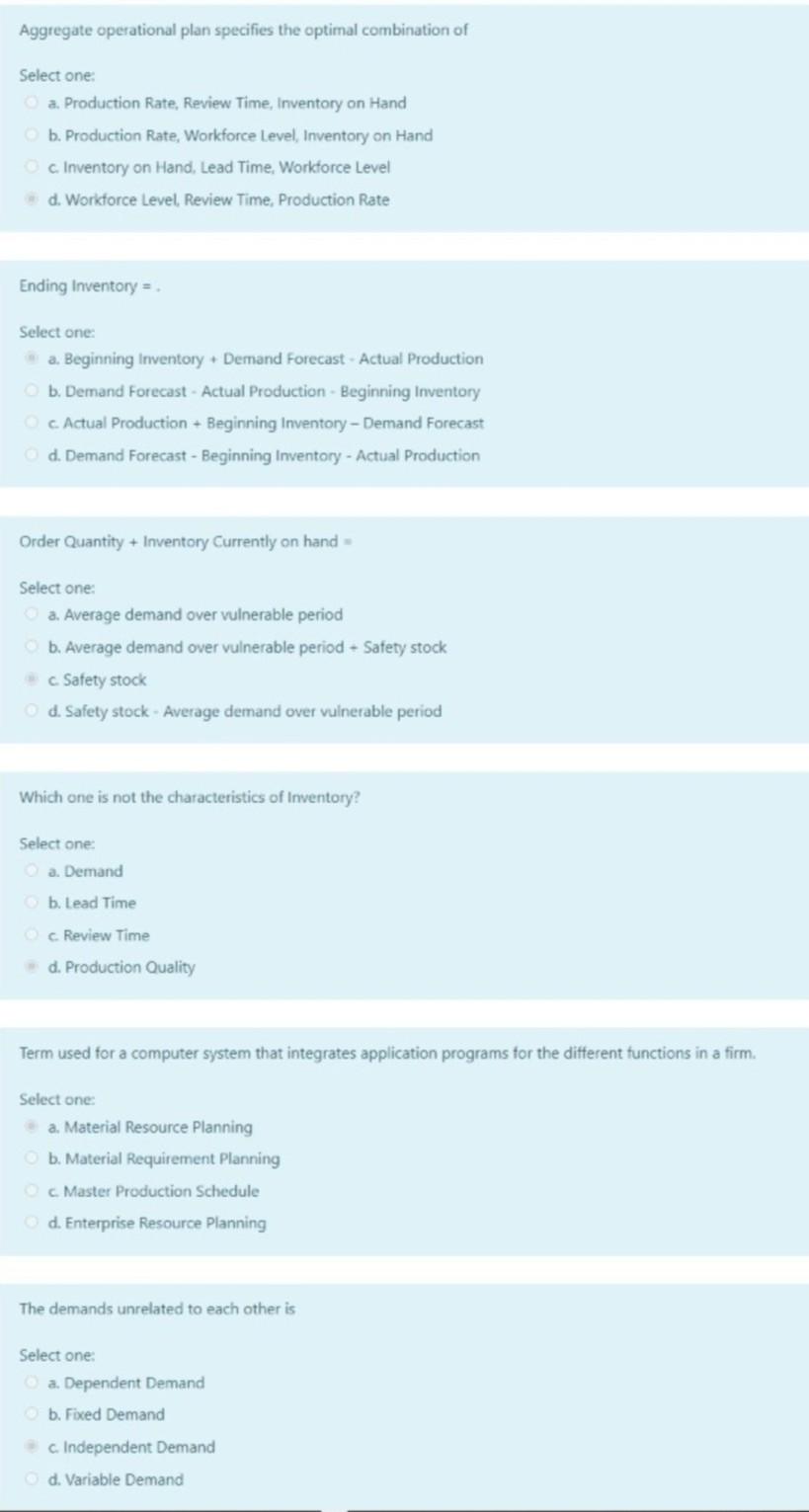

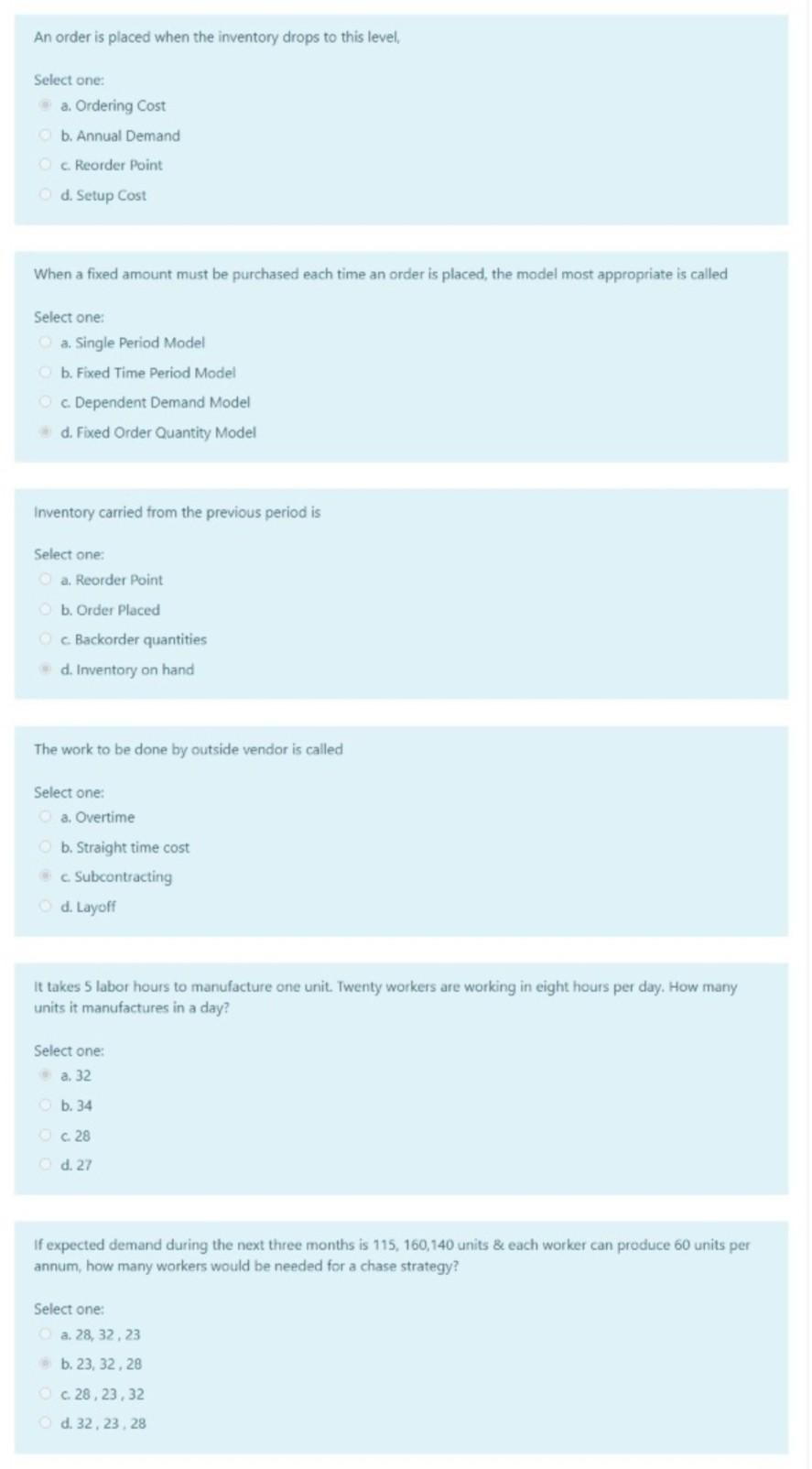

Aggregate operational plan specifies the optimal combination of Select one: a. Production Rate, Review Time, Inventory on Hand b. Production Rate, Workforce Level, Inventory on Hand c. Inventory on Hand, Lead Time, Workforce Level d. Workforce Level. Review Time, Production Rate Ending Inventory = Select one: a. Beginning Inventory - Demand Forecast - Actual Production b. Demand Forecast - Actual Production - Beginning Inventory cActual Production + Beginning Inventory - Demand Forecast d. Demand Forecast - Beginning Inventory - Actual Production Order Quantity + Inventory Currently on hand Select one: a. Average demand over vulnerable period b. Average demand over vulnerable period + Safety stock c Safety stock d. Safety stock - Average demand over vulnerable period Which one is not the characteristics of Inventory? Select one: a. Demand b. Lead Time c Review Time d. Production Quality Term used for a computer system that integrates application programs for the different functions in a firm. Select one a. Material Resource Planning b. Material Requirement Planning c Master Production Schedule d. Enterprise Resource Planning The demands unrelated to each other is Select one: a. Dependent Demand b. Fixed Demand c Independent Demand d. Variable Demand An order is placed when the inventory drops to this level Select one: a. Ordering Cost b. Annual Demand Reorder Point d. Setup Cost When a fixed amount must be purchased each time an order is placed, the model most appropriate is called Select one: a. Single Period Model b. Fixed Time Period Model c Dependent Demand Model d. Fixed Order Quantity Model Inventory carried from the previous period is Select one a. Reorder Point b. Order Placed c Backorder quantities d. Inventory on hand The work to be done by outside vendor is called Select one: a. Overtime b. Straight time cost c Subcontracting d. Layoff It takes 5 labor hours to manufacture one unit. Twenty workers are working in eight hours per day. How many units it manufactures in a day? Select one: a. 32 b. 34 c28 d. 27 If expected demand during the next three months is 115, 160, 140 units & each worker can produce 60 units per annum, how many workers would be needed for a chase strategy? Select one: a. 28, 32, 23 b. 23, 32, 28 c. 28, 23.32 d. 32, 23.28 Which of the followings Production Planning Strategy that match the production rate to the order rate by hiring & laying of employees? Select one: Level Stable workforce-constant work hours Chase d. Stable workforce variable work hours When inventory is replenished only in fixed intervals of time -for example on the first Sunday of the month is called Select one Single Period Model Fixed Time Period Model Feed Order Quantity Model d. Economic Order Quantity Model A process of taking a larger operation and bresicing it into smaller plans and shorter time periods. Select one a Aggregate Plan b. Master Production Schedule Fired time period model d. Production Rate Inventory Positions Select one: a On hand. On order - Backorder b. On crder-Backorder-On hand On hand - On order Backorder d. On order - On hand-Backorder Product/Services are made to customer specifications starts only when the order is received Example: Birthday Cake This type of Operating System is called Select one: a Assemble to Stock (ATS) Assemble to Order (ATO) Make to Order MTO) d. Make to Stock (MTS) A strategy where production rate is set to meet expected demand Select one: 2. Inventory on hand Level Strategy c. Stable Woridorce variable work hours d. Chase Little Grains has an item that it stock in store has fairly steady demand. One of the suppier insists that little Grains has to buy 20 unts at a time. The lead times very short on the item because the supplier is only few blocks away & Little grains can pick up another 20 untis when it run out. If Little Grains expect to sell 220 units next year how many trips will Little Grains need to make to the supplier over the year? Select one 11 6.21 12 d. 10 A feature of MRP systems that identifies the difference between the number of units currently included in the master schedule and the actuallfirm) customer orders Select one Available to Promise Slushy Liquid d. Frozen

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock