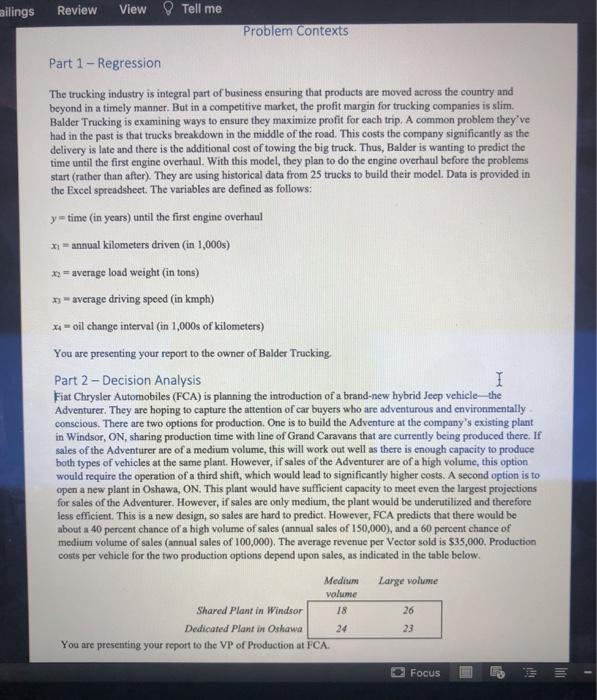

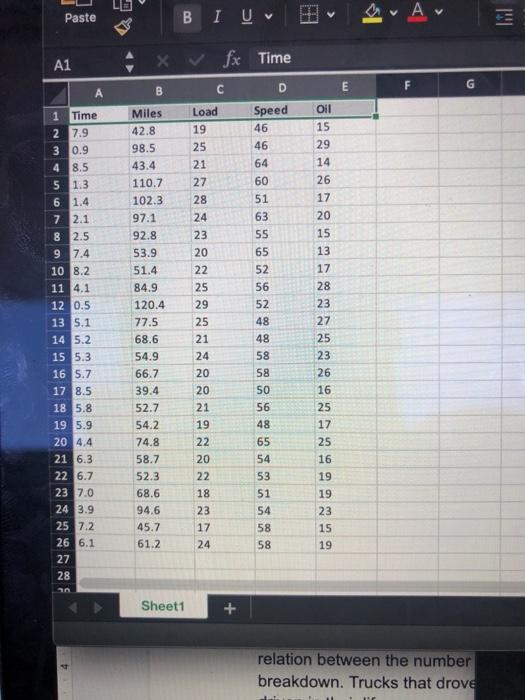

ailings Review View Tell me Problem Contexts Part 1 - Regression The trucking industry is integral part of business ensuring that products are moved across the country and beyond in a timely manner. But in a competitive market, the profit margin for trucking companies is slim. Balder Trucking is examining ways to ensure they maximize profit for each trip. A common problem they've had in the past is that trucks breakdown in the middle of the road. This costs the company significantly as the delivery is late and there is the additional cost of towing the big truck. Thus, Balder is wanting to predict the time until the first engine overhaul. With this model, they plan to do the engine overhaul before the problema start (rather than after). They are using historical data from 25 trucks to build their model. Data is provided in the Excel spreadsheet. The variables are defined as follows: y=time (in years) until the first engine overhaul 11 - annual kilometers driven (in 1,000s) x2 = average load weight (in tons) 33 - average driving speed (in kmph) *-= oil change interval (in 1.000s of kilometers) You are presenting your report to the owner of Balder Tracking Part 2 - Decision Analysis I Fiat Chrysler Automobiles (FCA) is planning the introduction of a brand-new hybrid Jeep vehiclethe Adventurer. They are hoping to capture the attention of car buyers who are adventurous and environmentally conscious. There are two options for production. One is to build the Adventure at the company's existing plant Windsor, ON, sharing production time with line of Grand Caravans that are currently being produced there. If sales of the Adventurer are of a medium volume, this will work out well as there is enough capacity to produce both types of vehicles at the same plant. However, if sales of the Adventurer are of a high volume, this option would require the operation of a third shift, which would lead to significantly higher costs. A second option is to open a new plant in Oshawa, ON. This plant would have sufficient capacity to meet even the largest projections for sales of the Adventurer. However, if sales are only medium, the plant would be underutilized and therefore less efficient. This is a new design, so sales are hard to predict. However, FCA predicts that there would be about a 40 percent chance of a high volume of sales annual sales of 150,000), and a 60 percent chance of medium volume of sales (annual sales of 100,000). The average revenue per Vector sold is $35,000. Production costs per vehicle for the two production options depend upon sales, as indicated in the tubic below. Medium Large volume volume Shared Plant in Windsor 18 Dedicated Plant in Oshawa 24 23 You are presenting your report to the VP of Production at FCA. 26 Focus lule E Paste BIU C. Av MI A1 fx Time D E F G B Oil 15 Speed 46 46 64 29 14 26 17 20 15 13 17 28 23 27 1 Time 2 7.9 3 0.9 4 8.5 5 1.3 6 1.4 7 2.1 8 2.5 9 7.4 10 8.2 11 4.1 12 0.5 13 5.1 14 5.2 15 5.3 16 5.7 17 8.5 18 5.8 19 5.9 20 4.4 21 6.3 22 6.7 23 7.0 24 3.9 25 7.2 26 6.1 27 28 Miles 42.8 98.5 43.4 110.7 102.3 97.1 92.8 53.9 51.4 84.9 120.4 77.5 68.6 54.9 66.7 39.4 52.7 54.2 74.8 58.7 52.3 68.6 94.6 45.7 61.2 Load 19 25 21 27 28 24 23 20 22 25 29 25 21 24 20 20 21 19 22 20 22 18 23 17 24 25 60 51 63 55 65 52 56 52 48 48 58 58 50 56 48 65 54 53 51 54 23 26 16 25 17 25 16 19 19 23 15 19 58 58 Sheet1 + relation between the number breakdown. Trucks that drove ailings Review View Tell me Problem Contexts Part 1 - Regression The trucking industry is integral part of business ensuring that products are moved across the country and beyond in a timely manner. But in a competitive market, the profit margin for trucking companies is slim. Balder Trucking is examining ways to ensure they maximize profit for each trip. A common problem they've had in the past is that trucks breakdown in the middle of the road. This costs the company significantly as the delivery is late and there is the additional cost of towing the big truck. Thus, Balder is wanting to predict the time until the first engine overhaul. With this model, they plan to do the engine overhaul before the problema start (rather than after). They are using historical data from 25 trucks to build their model. Data is provided in the Excel spreadsheet. The variables are defined as follows: y=time (in years) until the first engine overhaul 11 - annual kilometers driven (in 1,000s) x2 = average load weight (in tons) 33 - average driving speed (in kmph) *-= oil change interval (in 1.000s of kilometers) You are presenting your report to the owner of Balder Tracking Part 2 - Decision Analysis I Fiat Chrysler Automobiles (FCA) is planning the introduction of a brand-new hybrid Jeep vehiclethe Adventurer. They are hoping to capture the attention of car buyers who are adventurous and environmentally conscious. There are two options for production. One is to build the Adventure at the company's existing plant Windsor, ON, sharing production time with line of Grand Caravans that are currently being produced there. If sales of the Adventurer are of a medium volume, this will work out well as there is enough capacity to produce both types of vehicles at the same plant. However, if sales of the Adventurer are of a high volume, this option would require the operation of a third shift, which would lead to significantly higher costs. A second option is to open a new plant in Oshawa, ON. This plant would have sufficient capacity to meet even the largest projections for sales of the Adventurer. However, if sales are only medium, the plant would be underutilized and therefore less efficient. This is a new design, so sales are hard to predict. However, FCA predicts that there would be about a 40 percent chance of a high volume of sales annual sales of 150,000), and a 60 percent chance of medium volume of sales (annual sales of 100,000). The average revenue per Vector sold is $35,000. Production costs per vehicle for the two production options depend upon sales, as indicated in the tubic below. Medium Large volume volume Shared Plant in Windsor 18 Dedicated Plant in Oshawa 24 23 You are presenting your report to the VP of Production at FCA. 26 Focus lule E Paste BIU C. Av MI A1 fx Time D E F G B Oil 15 Speed 46 46 64 29 14 26 17 20 15 13 17 28 23 27 1 Time 2 7.9 3 0.9 4 8.5 5 1.3 6 1.4 7 2.1 8 2.5 9 7.4 10 8.2 11 4.1 12 0.5 13 5.1 14 5.2 15 5.3 16 5.7 17 8.5 18 5.8 19 5.9 20 4.4 21 6.3 22 6.7 23 7.0 24 3.9 25 7.2 26 6.1 27 28 Miles 42.8 98.5 43.4 110.7 102.3 97.1 92.8 53.9 51.4 84.9 120.4 77.5 68.6 54.9 66.7 39.4 52.7 54.2 74.8 58.7 52.3 68.6 94.6 45.7 61.2 Load 19 25 21 27 28 24 23 20 22 25 29 25 21 24 20 20 21 19 22 20 22 18 23 17 24 25 60 51 63 55 65 52 56 52 48 48 58 58 50 56 48 65 54 53 51 54 23 26 16 25 17 25 16 19 19 23 15 19 58 58 Sheet1 + relation between the number breakdown. Trucks that drove