Question: An axially loaded component experiences push - pull axial loading to a maximum tensile stress of 1 6 4 - MPa and a minimum compressive

An axially loaded component experiences pushpull axial loading to a maximum tensile stress of MPa and a minimum compressive stress of MPa. Calculate the stress amplitude and the mean stress.

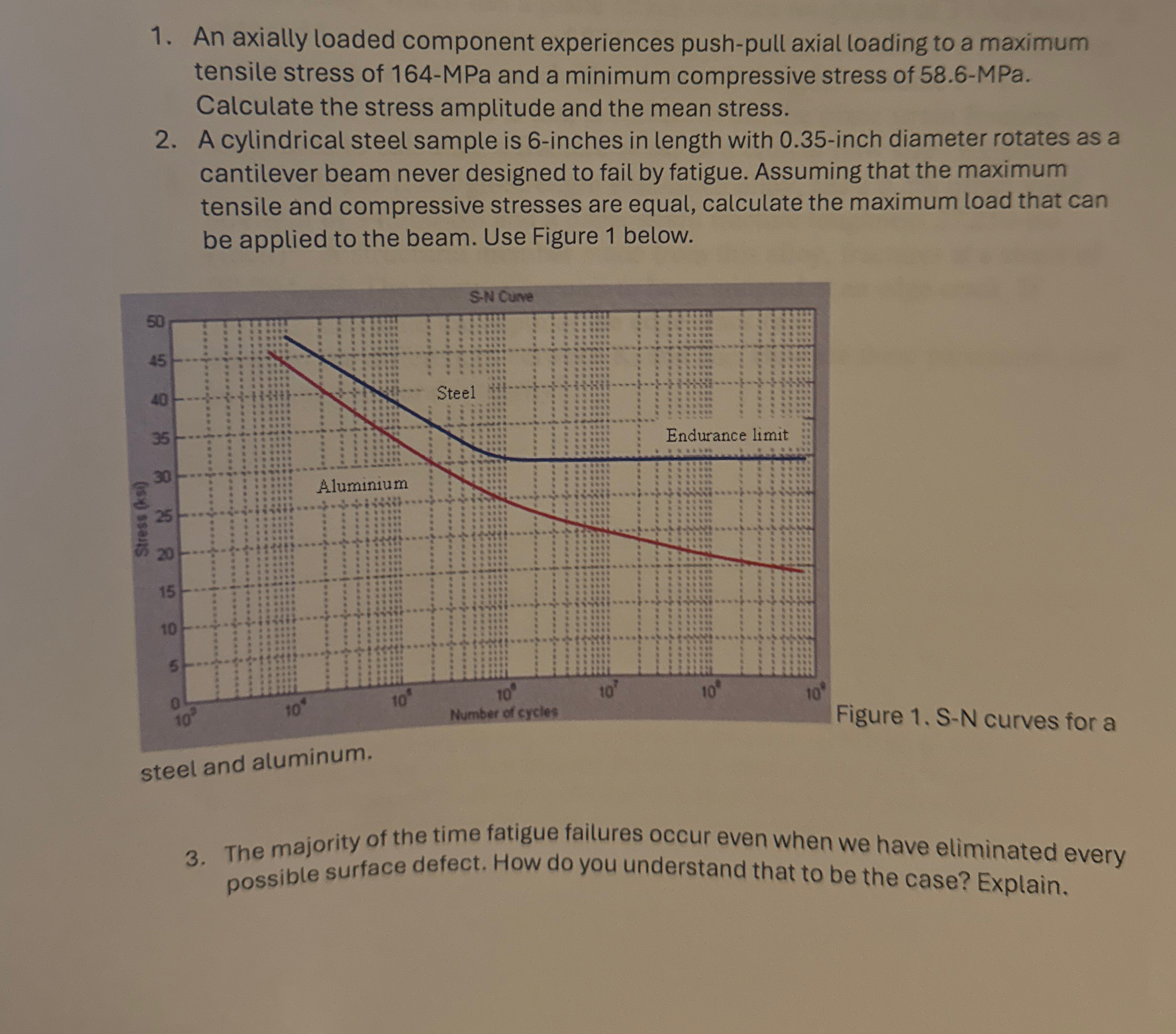

A cylindrical steel sample is inches in length with inch diameter rotates as a cantilever beam never designed to fail by fatigue. Assuming that the maximum tensile and compressive stresses are equal, calculate the maximum load that can be applied to the beam. Use Figure below.

Figure SN curves for a steel and aluminum.

The majority of the time fatigue failures occur even when we have eliminated every possible surface defect. How do you understand that to be the case? Explain.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock