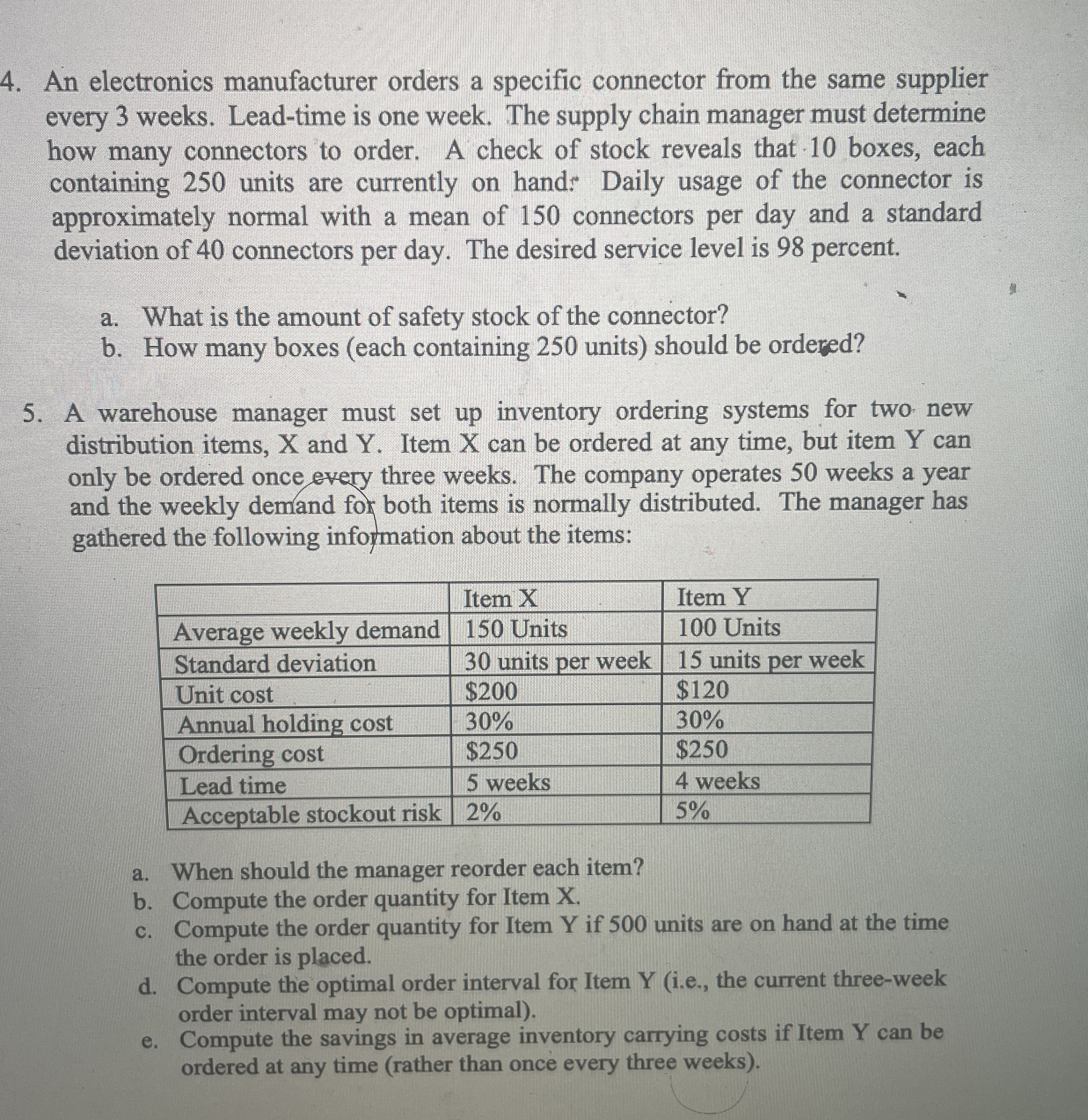

Question: An electronics manufacturer orders a specific connector from the same supplier every 3 weeks. Lead - time is one week. The supply chain manager must

An electronics manufacturer orders a specific connector from the same supplier

every weeks. Leadtime is one week. The supply chain manager must determine

how many connectors to order. A check of stock reveals that boxes, each

containing units are currently on hand: Daily usage of the connector is

approximately normal with a mean of connectors per day and a standard

deviation of connectors per day. The desired service level is percent.

a What is the amount of safety stock of the connector?

b How many boxes each containing units should be ordered?

A warehouse manager must set up inventory ordering systems for two new

distribution items, X and Y Item X can be ordered at any time, but item Y can

only be ordered once every three weeks. The company operates weeks a year

and the weekly demand for both items is normally distributed. The manager has

gathered the following information about the items:

a When should the manager reorder each item?

b Compute the order quantity for Item

c Compute the order quantity for Item Y if units are on hand at the time

the order is placed.

d Compute the optimal order interval for Item Y ie the current threeweek

order interval may not be optimal

e Compute the savings in average inventory carrying costs if Item Y can be

ordered at any time rather than once every three weeks

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock