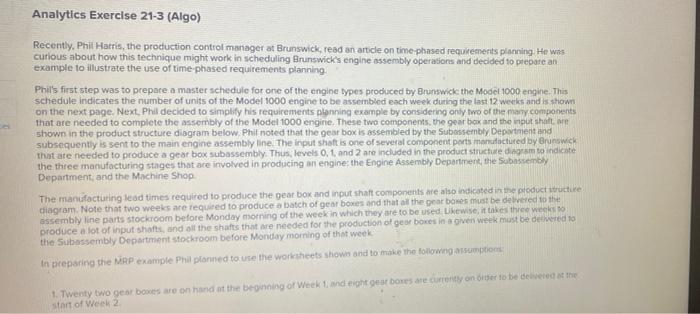

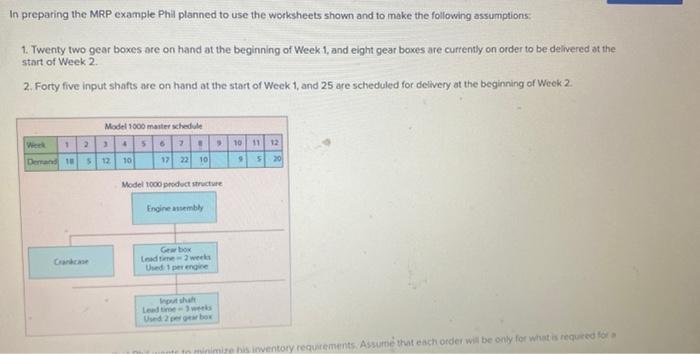

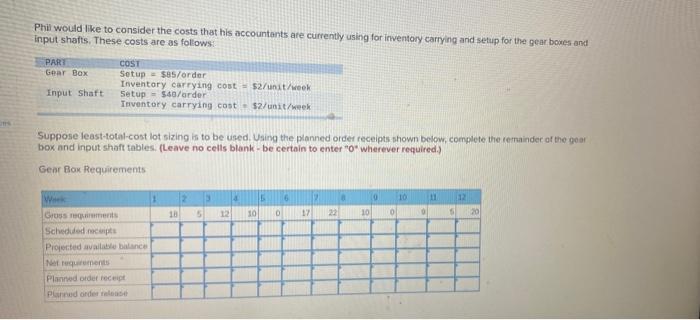

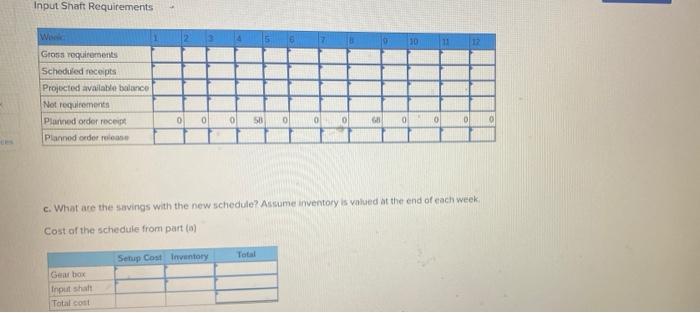

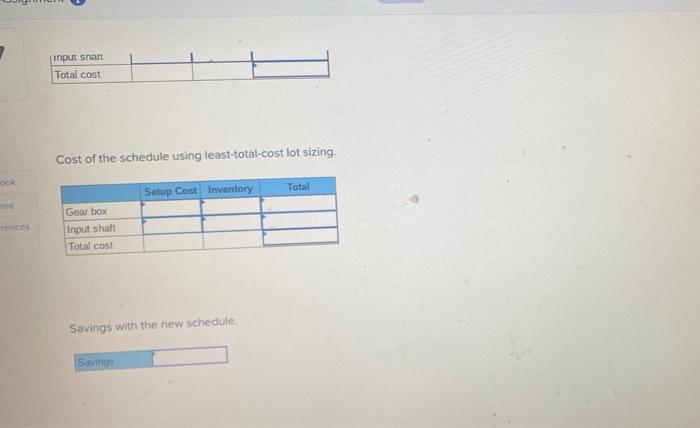

Question: Analytics Exercise 21-3 (Algo) Recently, Phil Hatris, the production control manager at Brunswick, read an article on time phased requirements planning. He was curious about

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock