Question: ANSWER 3 & 4 BASED ON 1 & 2 answers given below: 1. Recently I had watched a How It's Made episode on toothpicks. During

ANSWER 3 & 4 BASED ON 1 & 2 answers given below: 1. Recently I had watched a "How It's Made" episode on toothpicks. During the manufacturing process of toothpicks, a top priority that must always be sought after, is the length of the toothpicks. If a manufacturing line is aiming to produce 250 millimeter long toothpicks, SPC can be utilized to determine the range of error that might occur during the manufacturing process. 2. I believe utilizing Statistical Process Control in this case is appropriate because we can accept toothpicks in the range of 240-260 millimeters. This range can be considered our upper and lower specification limits. Otherwise, the toothpicks would be too small or too large for packaging.

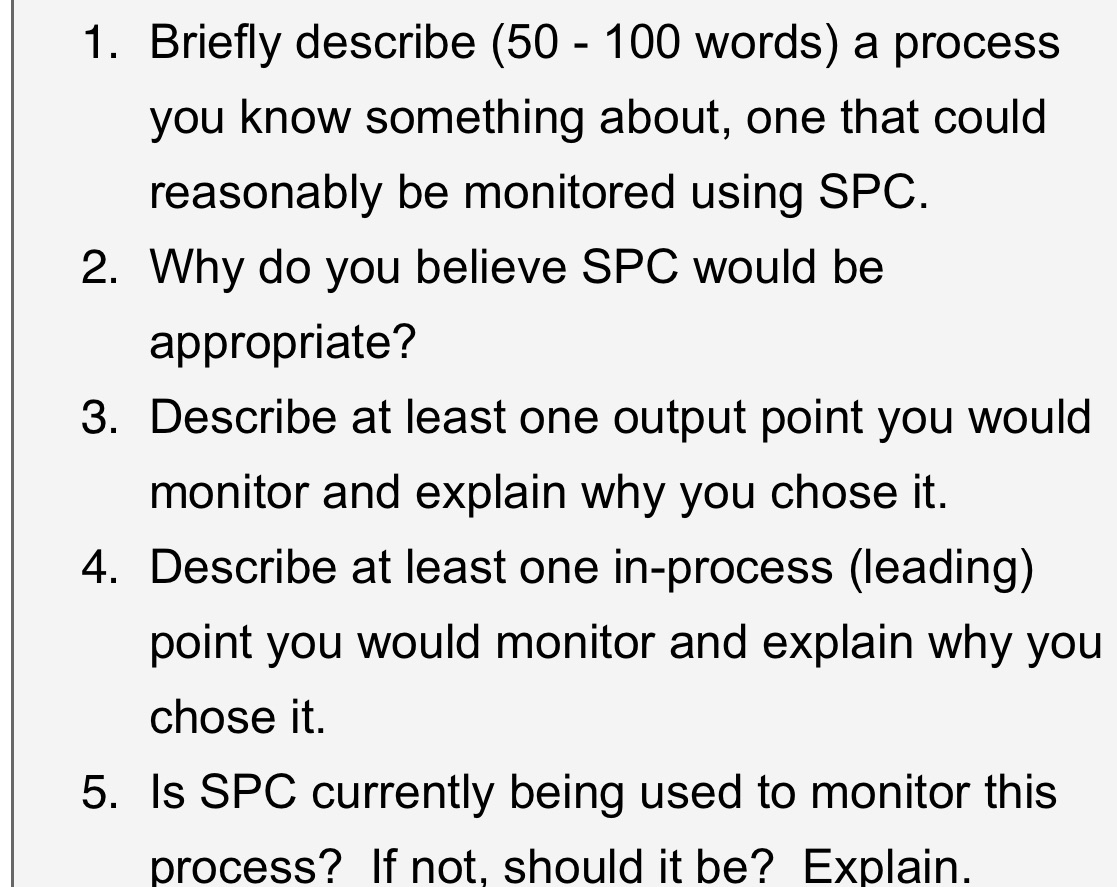

1. Briefly describe (50 - 100 words) a process you know something about, one that could reasonably be monitored using SPC. Why do you believe SPC would be appropriate? Describe at least one output point you would monitor and explain why you chose it. Describe at least one in-process (leading) point you would monitor and explain why you choseit Is SPC currently being used to monitor this Drocess? If not. should it be? Explain

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts