Question: ANSWER - A-ii and C Please, will give 100% Thumbs up if answered ANSWER - A-ii and C Please, will give 100% Thumbs up if

ANSWER - A-ii and C Please, will give 100% Thumbs up if answered

ANSWER - A-ii and C Please, will give 100% Thumbs up if answered

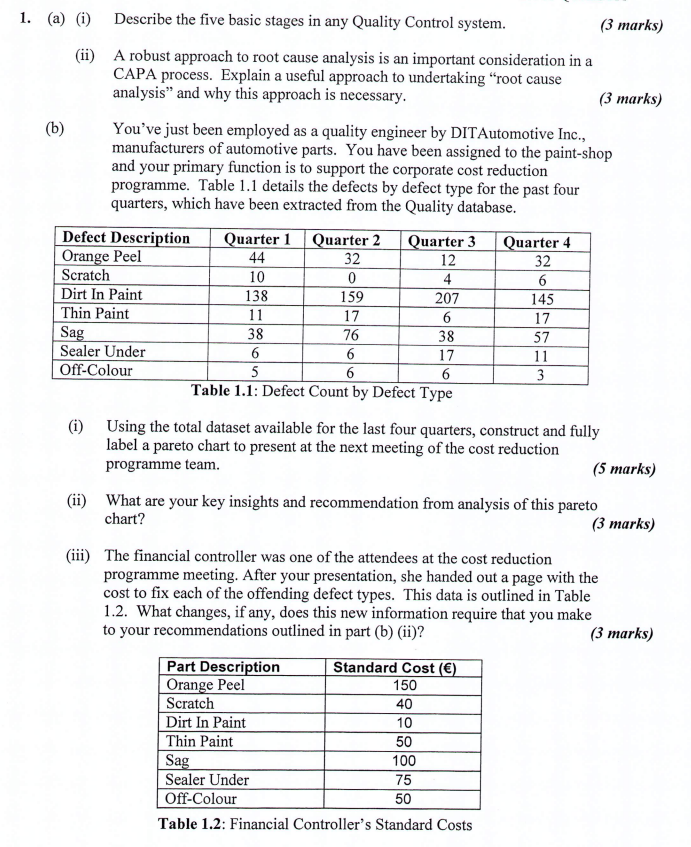

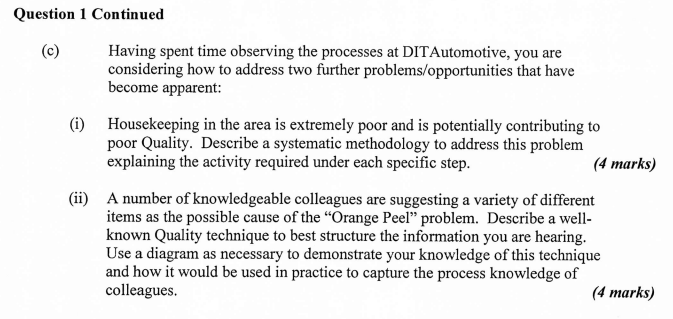

1. (a) (i) Describe the five basic stages in any Quality Control system. (3 marks) (ii) A robust approach to root cause analysis is an important consideration in a CAPA process. Explain a useful approach to undertaking root cause analysis and why this approach is necessary. (3 marks) (b) You've just been employed as a quality engineer by DITAutomotive Inc., manufacturers of automotive parts. You have been assigned to the paint-shop and your primary function is to support the corporate cost reduction programme. Table 1.1 details the defects by defect type for the past four quarters, which have been extracted from the Quality database. Defect Description Quarter 1 Quarter 2 Quarter 3 Quarter 4 Orange Peel 44 32 12 32 Scratch 10 0 4 6 Dirt In Paint 138 159 207 145 Thin Paint 11 17 6 17 Sag 38 76 38 57 Sealer Under 6 6 17 11 Off-Colour 5 6 6 3 Table 1.1: Defect Count by Defect Type (1) Using the total dataset available for the last four quarters, construct and fully label a pareto chart to present at the next meeting of the cost reduction programme team. (5 marks) (ii) What are your key insights and recommendation from analysis of this pareto chart? (3 marks) (iii) The financial controller was one of the attendees at the cost reduction programme meeting. After your presentation, she handed out a page with the cost to fix each of the offending defect types. This data is outlined in Table 1.2. What changes, if any, does this new information require that you make to your recommendations outlined in part (b) (ii)? (3 marks) Part Description Standard Cost () Orange Peel 150 Scratch 40 Dirt In Paint 10 Thin Paint 50 Sag 100 Sealer Under 75 Off-Colour 50 Table 1.2: Financial Controller's Standard Costs Question 1 Continued Having spent time observing the processes at DITAutomotive, you are considering how to address two further problems/opportunities that have become apparent: (1) Housekeeping in the area is extremely poor and is potentially contributing to poor Quality. Describe a systematic methodology to address this problem explaining the activity required under each specific step. (4 marks) (ii) A number of knowledgeable colleagues are suggesting a variety of different items as the possible cause of the "Orange Peel" problem. Describe a well- known Quality technique to best structure the information you are hearing. Use a diagram as necessary to demonstrate your knowledge of this technique and how it would be used in practice to capture the process knowledge of colleagues. (4 marks)Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts