Question: answer all questions please :( A local company makes athletic clothing and they are preparing aggregate production plans on a quarterly basis for the coming

answer all questions please :(

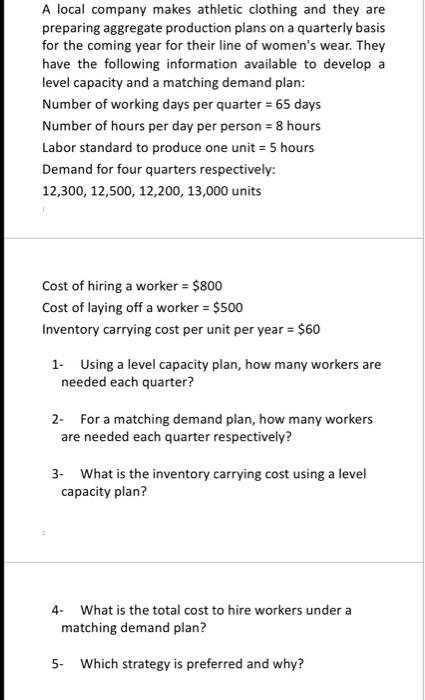

A local company makes athletic clothing and they are preparing aggregate production plans on a quarterly basis for the coming year for their line of women's wear. They have the following information available to develop a level capacity and a matching demand plan: Number of working days per quarter = 65 days Number of hours per day per person = 8 hours Labor standard to produce one unit = 5 hours Demand for four quarters respectively: 12,300, 12,500, 12,200, 13,000 units Cost of hiring a worker = $800 Cost of laying off a worker = $500 Inventory carrying cost per unit per year = $60 1. Using a level capacity plan, how many workers are needed each quarter? 2- For a matching demand plan, how many workers are needed each quarter respectively? 3- What is the inventory carrying cost using a level capacity plan? 4. What is the total cost to hire workers under a matching demand plan? 5- Which strategy is preferred and why

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock