Question: answer asap QUESTION FOUR (25 MARKS) A. Based on the MRP diagram below, complete the MRP tables based on the given lot sizing together with

answer asap

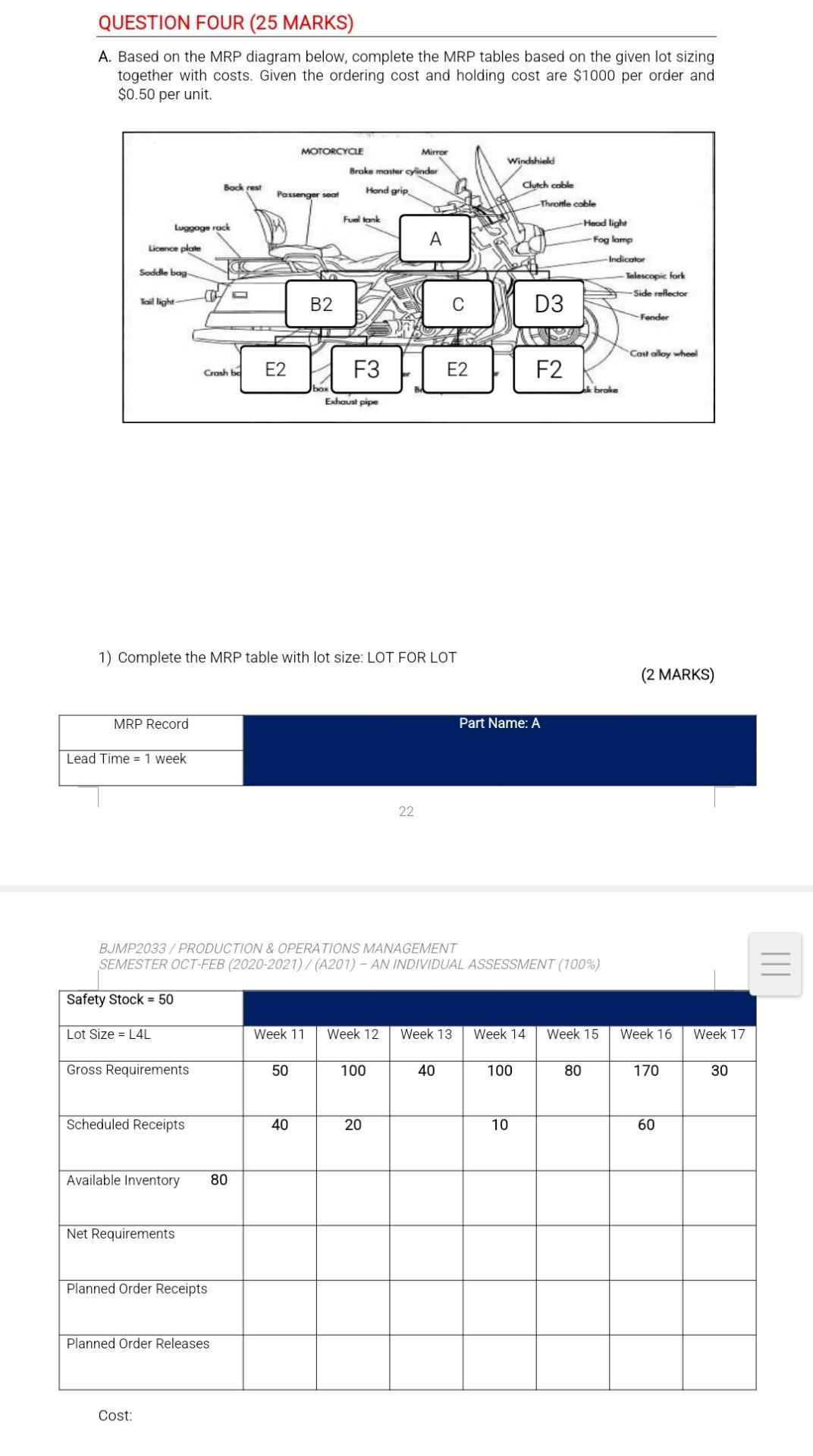

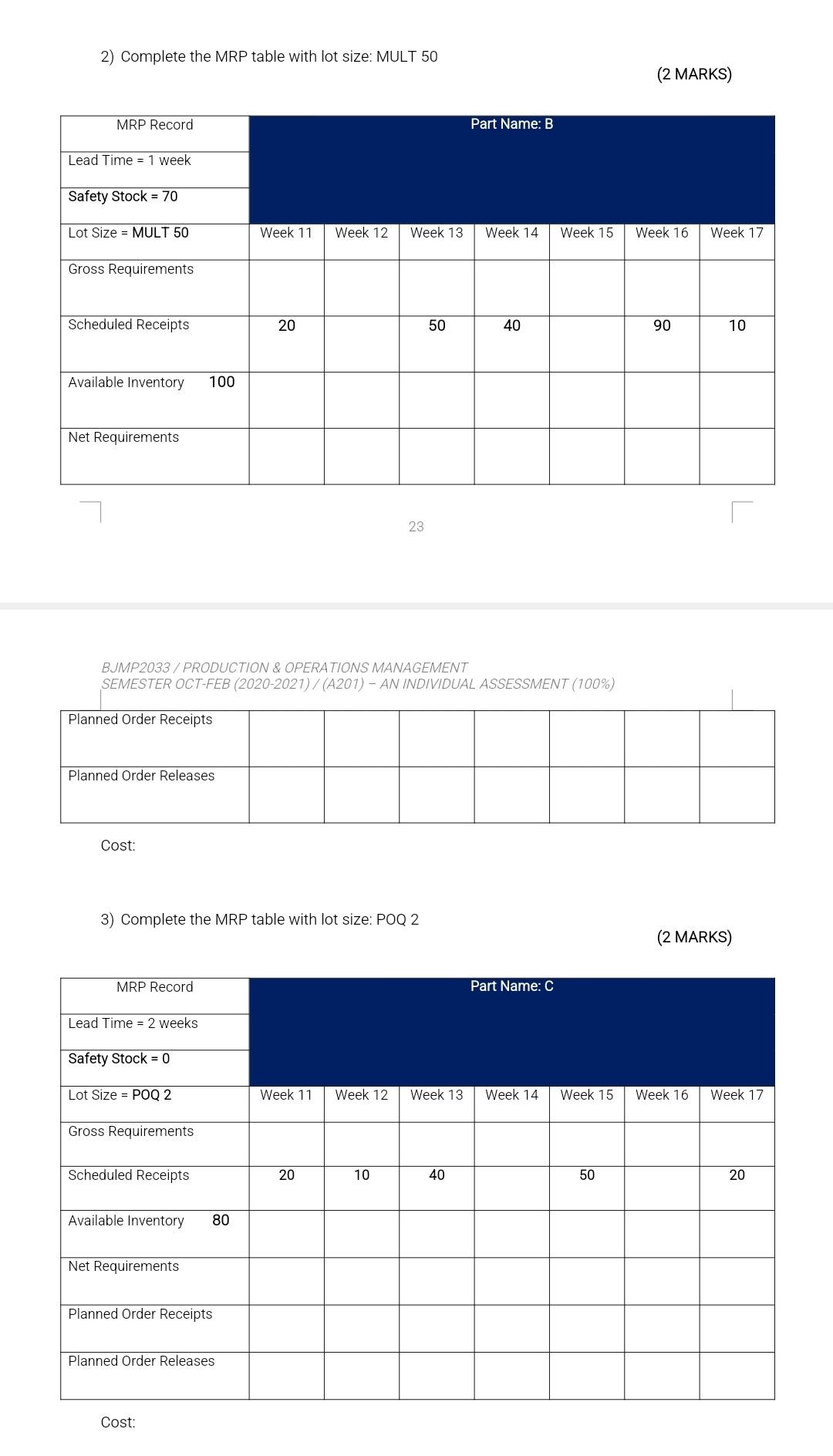

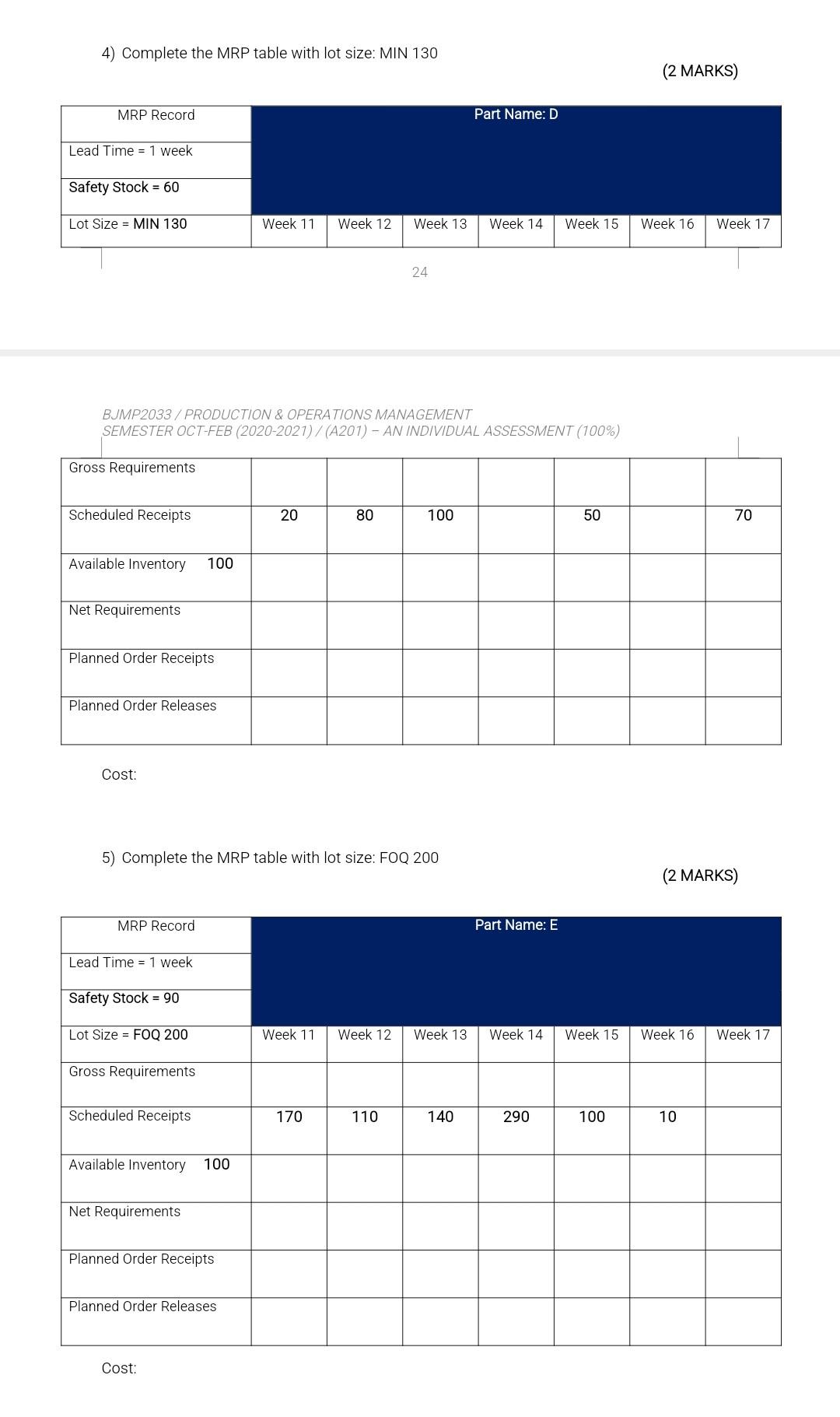

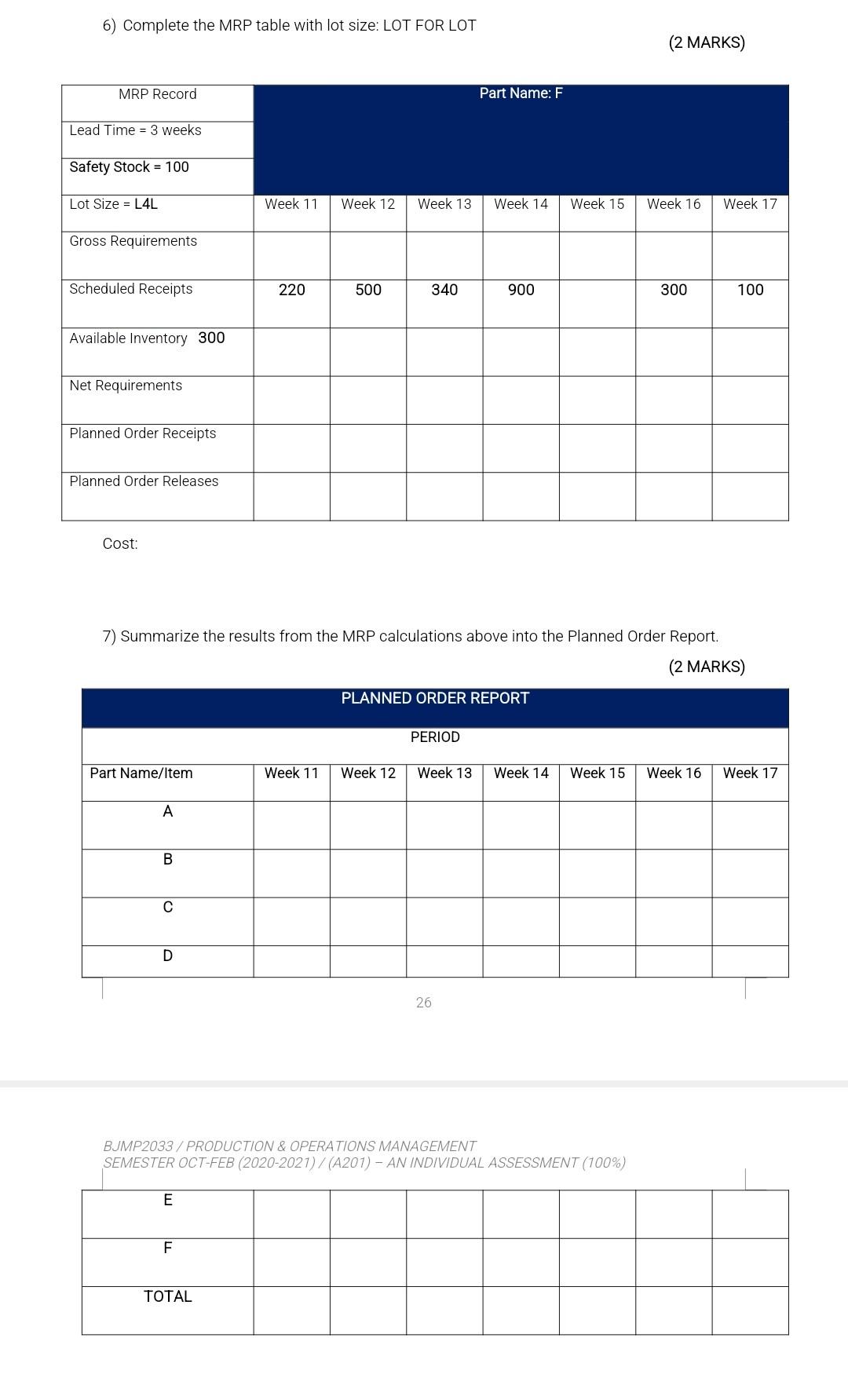

QUESTION FOUR (25 MARKS) A. Based on the MRP diagram below, complete the MRP tables based on the given lot sizing together with costs. Given the ordering cost and holding cost are $1000 per order and $0.50 per unit. MOTORCYCLE Mirror Broke master cylinder Windshield Bock rest Passenger seat Hond grip Clutch cable Fuel tank Luggage rock A Licence plate Throttle cable Head light -Fog lamp Indicator Telescopic fork Side reflector Soddle bag TH Tail light B2 D3 Fender Cow alloy wheel Grosh bo E2 F3 E2 F2 broke Exhaust pipe 1) Complete the MRP table with lot size: LOT FOR LOT (2 MARKS) MRP Record Part Name: A Lead Time = 1 week 22 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB (2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) Safety Stock = 50 Lot Size = L4L Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements 50 100 40 100 80 170 30 Scheduled Receipts 40 20 10 60 Available Inventory 80 Net Requirements Planned Order Receipts Planned Order Releases Cost: 2) Complete the MRP table with lot size: MULT 50 (2 MARKS) MRP Record Part Name: B Lead Time = 1 week Safety Stock = 70 Lot Size = MULT 50 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 20 50 40 90 10 Available Inventory 100 Net Requirements L 23 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB (2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) Planned Order Receipts Planned Order Releases Cost: 3) Complete the MRP table with lot size: POQ 2 (2 MARKS) MRP Record Part Name: C Lead Time = 2 weeks Safety Stock = 0 Lot Size = POQ 2 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 20 10 40 50 20 Available Inventory 80 Net Requirements Planned Order Receipts Planned Order Releases Cost: 4) Complete the MRP table with lot size: MIN 130 (2 MARKS) MRP Record Part Name: D Lead Time = 1 week Safety Stock = 60 Lot Size = MIN 130 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 24 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB 2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) Gross Requirements Scheduled Receipts 20 80 100 50 70 Available Inventory 100 Net Requirements Planned Order Receipts Planned Order Releases Cost: 5) Complete the MRP table with lot size: FOQ 200 (2 MARKS) MRP Record Part Name: E Lead Time = 1 week Safety Stock = 90 Lot Size = FOQ 200 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 170 110 140 290 100 10 Available Inventory 100 Net Requirements Planned Order Receipts Planned Order Releases Cost: 6) Complete the MRP table with lot size: LOT FOR LOT (2 MARKS) MRP Record Part Name: F Lead Time = 3 weeks Safety Stock = 100 Lot Size = L4L Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 220 500 340 900 300 100 Available Inventory 300 Net Requirements Planned Order Receipts Planned Order Releases Cost: 7) Summarize the results from the MRP calculations above into the planned Order Report. (2 MARKS) PLANNED ORDER REPORT PERIOD Part Name/Item Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 A B D 26 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB (2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) E F TOTAL QUESTION FOUR (25 MARKS) A. Based on the MRP diagram below, complete the MRP tables based on the given lot sizing together with costs. Given the ordering cost and holding cost are $1000 per order and $0.50 per unit. MOTORCYCLE Mirror Broke master cylinder Windshield Bock rest Passenger seat Hond grip Clutch cable Fuel tank Luggage rock A Licence plate Throttle cable Head light -Fog lamp Indicator Telescopic fork Side reflector Soddle bag TH Tail light B2 D3 Fender Cow alloy wheel Grosh bo E2 F3 E2 F2 broke Exhaust pipe 1) Complete the MRP table with lot size: LOT FOR LOT (2 MARKS) MRP Record Part Name: A Lead Time = 1 week 22 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB (2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) Safety Stock = 50 Lot Size = L4L Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements 50 100 40 100 80 170 30 Scheduled Receipts 40 20 10 60 Available Inventory 80 Net Requirements Planned Order Receipts Planned Order Releases Cost: 2) Complete the MRP table with lot size: MULT 50 (2 MARKS) MRP Record Part Name: B Lead Time = 1 week Safety Stock = 70 Lot Size = MULT 50 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 20 50 40 90 10 Available Inventory 100 Net Requirements L 23 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB (2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) Planned Order Receipts Planned Order Releases Cost: 3) Complete the MRP table with lot size: POQ 2 (2 MARKS) MRP Record Part Name: C Lead Time = 2 weeks Safety Stock = 0 Lot Size = POQ 2 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 20 10 40 50 20 Available Inventory 80 Net Requirements Planned Order Receipts Planned Order Releases Cost: 4) Complete the MRP table with lot size: MIN 130 (2 MARKS) MRP Record Part Name: D Lead Time = 1 week Safety Stock = 60 Lot Size = MIN 130 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 24 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB 2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) Gross Requirements Scheduled Receipts 20 80 100 50 70 Available Inventory 100 Net Requirements Planned Order Receipts Planned Order Releases Cost: 5) Complete the MRP table with lot size: FOQ 200 (2 MARKS) MRP Record Part Name: E Lead Time = 1 week Safety Stock = 90 Lot Size = FOQ 200 Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 170 110 140 290 100 10 Available Inventory 100 Net Requirements Planned Order Receipts Planned Order Releases Cost: 6) Complete the MRP table with lot size: LOT FOR LOT (2 MARKS) MRP Record Part Name: F Lead Time = 3 weeks Safety Stock = 100 Lot Size = L4L Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 Gross Requirements Scheduled Receipts 220 500 340 900 300 100 Available Inventory 300 Net Requirements Planned Order Receipts Planned Order Releases Cost: 7) Summarize the results from the MRP calculations above into the planned Order Report. (2 MARKS) PLANNED ORDER REPORT PERIOD Part Name/Item Week 11 Week 12 Week 13 Week 14 Week 15 Week 16 Week 17 A B D 26 BJMP2033 / PRODUCTION & OPERATIONS MANAGEMENT SEMESTER OCT-FEB (2020-2021)/(A201) - AN INDIVIDUAL ASSESSMENT (100%) E F TOTAL

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock