Question: answer B, using the answers i provide for A (below) A) The cost of processing cartons through the facility To calculate the cost of processing

answer B, using the answers i provide for A (below)

A)

The cost of processing cartons through the facility

To calculate the cost of processing cartons through the facility we need to first subtract the truck drivers expenses from the personnel expenses as it includes both warehouse and truck drivers expense and then we need to add warehouse expenses (excluding personnel) to it.

Cost of processing = ($2,570,000 - $250,000) + $2,000,000

= $4,320,000

Capacity that could be handled = 80,000 cartons

Cost per carton = $4,320,000/80,000 = $54 per carton

This scenario is solved by assuming all the cartons used for processing are of the same size, arrived and stored in the facility for the same amount of time. Otherwise, the calculations will be complex, and a detailed ABC cost system should be used to solve it.

The cost of entering electronic and manual customer orders

As mentioned, Midwest employed 16 order entry operators with annual expenses of $840,000 which includes salaries, supervision and equipment costs and other benefits for the operators.

Order entry expenses = $840,000

Number of employees employed = 16

Each employee works for average of 1,500 productive hours per year after removing vacations, breaks and holidays

Capacity of resources = 1500 x 16 = 24,000 hours

Cost of manual order entry = $35/hour.

Time taken to enter a customer order manually = Time taken to enter basic information +

Additional time taken to enter each line item on the order

= 0.15 hour + 0.075 hour = 0.225 hour

Total cost to entering manual customer order = 0.225hr x $35/ hour = $7.875 per entry

Operator spends an average of 0.10 hour to verify electronic order information and it requires no additional time for line item.

Cost for verifying information on electronic customer order = 0.10 hour x $35/ hour = $3.5 per entry

The main assumption when calculating the cost of order entry is that the complexity of all electronic orders requires the same amount of time to validate or verify, and all manual orders take the same amount of time to enter the basic information (except line items)

The cost of shipping cartons on commercial carriers

Assuming that each carton shipped by commercial carrier costs around the same, whatever the weight or distance, we can estimate the cost per carton using the total freight expenses and the total number of cartons shipped by commercial freight.

Cost of commercial freight = $450,000

Number of cartons shipped = 75,000

Shipping cost of each carton = $450,000/75,000 = $6 per carton

The cost per hour for desktop deliveries

Midwest leased 4 trucks and hired 4 drivers for desktop delivery services.

Each truck driver worked for a max of 1500 hours and the maximum available time for each truck is 1500 hours after service and maintenance.

Therefore, hours available for desktop delivery = 1500 hours x 4 = 6000hrs

Based on Time-Driven approach we can calculate the delivery cost per hour for desktops

Delivery resources cost is calculated by adding delivery truck expenses and truck driver compensation = $200,000 + $250,000 = $450,000

Cost per hour to deliver desktops = $450,000/6000 = $75/ hour

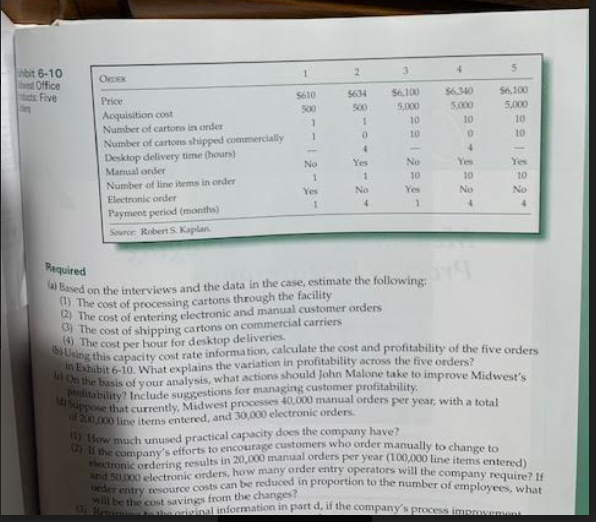

Pequired (a) Bived on the interviews and the data in the case, estimate the following: (1) The cost of processing cartons through the facility (2) The cost of entering electronic and manual customer orders (3) The cost of shipping cartons on commercial carriers (4) The cost per hour for desktop de liveries. b) Using this capacity cost rate information, calculate the cost and profitability of the five onders in tyhibit 6-10. What explains the variation in profitability across the five orders? ki go the basis of your analysis, what actions should John Malone take to improve Midwest's pelitability? Include saggestions for managing customer profitability. Grgere that currently, Midwest processes 40,000 manual orders per year, with a total 10) How much unused practical capacity does the company have? (2) If the company's efforts to encourage castomers who order manually to change to rectronic ordering results in 20,000 manual orders per year (100,000 line items entered) at \\( 5(1,000 \\) electronic orders, how many order entry operators will the company require? If order entry cesource costs can be reduced in proportion to the number of employees, what Wille the cost savings from the changes

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts