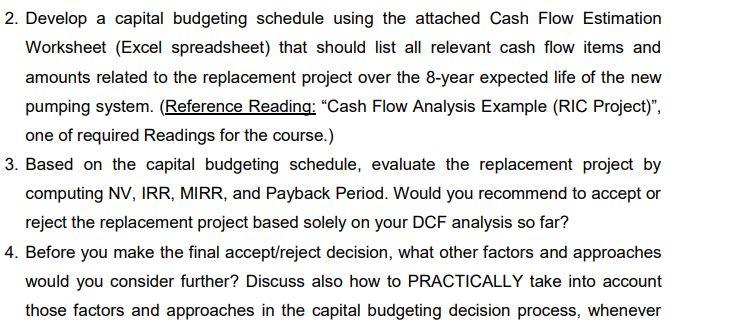

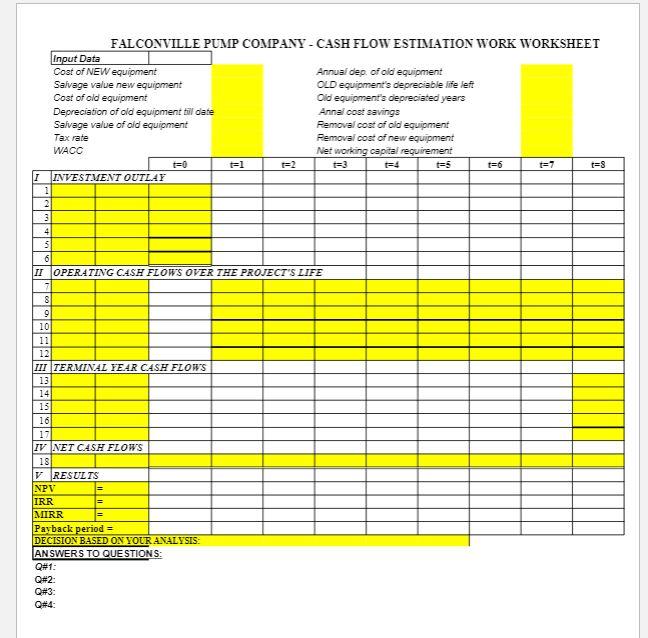

Question: Answer Doc for 2 looks like this below ( cash flow estimation chart) Joiner decided that the best course of action was first, to find

Answer Doc for 2 looks like this below ( cash flow estimation chart)

Joiner decided that the best course of action was first, to find out how well Stewart is versed in capital budgeting techniques, and second, if the training proves to be adequate, to ask her to work on the marketing division project during her internship. When Joiner questioned Stewart, he was delighted to learn that not only had she worked in the economic evaluation department in her former job, she also had taken an entire course dealing with capital expenditure decisions. (Stewart, for her part, was surprised to learn that FPC was still using the payback method.) She readily agreed to the assignment in the marketing department, and she and Avery decided to start by analyzing one of the standard pumping systems. The following facts, which Avery indicated were fairly typical, were to be used in the illustrative material: 1. The equipment has a delivered cost of $105,000. An additional $3,000 is required to install and test the new system. 2. The new pumping system is classified by the IRS as 5-year property, although it has an 8-year estimated service life. For assets classified by the IRS as 5-year property, the Modified Accelerated Cost Recovery System (MACRS) permits the company to depreciate the asset over 6 years at the following rates: Year 1 = 20 percent, Year 2 = 32 percent, Year 3 = 19 percent, Year 4 = 12 percent, Year 5 = 11 percent, Year 6 = 6 percent. At the end of 8 years, the salvage value is expected to be around 5 percent of the original purchase price, so the best estimate of salvage value at the end of the equipment's service life is $5,300, with removal costs of $1,200. 3. The existing pumping system was purchased at $45,000 eight years ago and has been depreciated on a straight-line basis over its economic life of 10 years. If the existing system is removed from the well and crated for pickup, it can be sold for $3,500 before tax. It will cost $1,000 to remove the system and crate it. 4. At the time of replacement, the firm will need to increase its net working capital requirements by $4,500 to support inventories. 5. The new pumping system offers lower maintenance costs and frees personnel who would otherwise have to monitor the system. In addition, it reduces product wastage because of a higher cooling efficiency. In total, it is estimated that the yearly savings will amount to $25,000 if the new pumping system is used. 6. The firm has its target debt ratio of 30 percent, and its cost of new debt is 10 percent. Its expected dividend per share next year, D1, is $2.00 with a future growth rate of 6 percent per year. The firm's current stock price, Po, is $40.00. The firm uses its overall weighted average cost of capital in evaluating average risk projects, and the replacement project is perceived to be of average risk. 7. The firm's federal-plus-state tax rate is 30 percent, and this rate is projected to remain fairly constant into the future. 1. Compute the firm's weighted average cost of capital given the info/data in the case. What other approaches/methods can be used to measure the firm's cost of equity and thus its WACC? To that end, what additional info/data would you need? (Hint: A firm's weighted average cost of capital is equal to Ka = W.(Ka)(1 - t) + W K, where We and We are the weights of debt and equity in the capital structure; Kd and Ke are the respective costs of debt and equity; and t is the corporate tax rate; Do no round up your WACC figure.) 2. Develop a capital budgeting schedule using the attached Cash Flow Estimation Worksheet (Excel spreadsheet) that should list all relevant cash flow items and amounts related to the replacement project over the 8-year expected life of the new pumping system. (Reference Reading: Cash Flow Analysis Example (RIC Project)", one of required Readings for the course.) 3. Based on the capital budgeting schedule, evaluate the replacement project by computing NV, IRR, MIRR, and Payback Period. Would you recommend to accept or reject the replacement project based solely on your DCF analysis so far? 4. Before you make the final accept/reject decision, what other factors and approaches would you consider further? Discuss also how to PRACTICALLY take into account those factors and approaches in the capital budgeting decision process, whenever FALCONVILLE PUMP COMPANY - CASH FLOW ESTIMATION WORK WORKSHEET Input Data Cost of NEW equipment Annual dep. of old equipment Salvage value new equipment OLD equipment's depreciable life left Coat of old equipment Olid equipment's depreciated years Depreciation of old equipment till dete Annal cost savings Salvage value of old equipment Removal cost of old equipment Tax rate Removal cost of new equipment WACC Networking capital requirement =0 =1 3 t=5 t=6 t=8 INVESTMENT OUTLAY 1 2 3 t=2 3 I 5 6 II OPERATING CASH FLOWS OVER THE PROJECT'S LIFE 7 8 9 10 11 12 III TERMINAL FEAR CASH FLOWS 13 14 15 16 17 IV NET CASH FLOWS 18 V RESULTS NPV IRR MIRR Payback period = DECISION BASED ON YOUR ANALYSIS: ANSWERS TO QUESTIONS: Q#1: Q#2: Q#3: Q#4 Joiner decided that the best course of action was first, to find out how well Stewart is versed in capital budgeting techniques, and second, if the training proves to be adequate, to ask her to work on the marketing division project during her internship. When Joiner questioned Stewart, he was delighted to learn that not only had she worked in the economic evaluation department in her former job, she also had taken an entire course dealing with capital expenditure decisions. (Stewart, for her part, was surprised to learn that FPC was still using the payback method.) She readily agreed to the assignment in the marketing department, and she and Avery decided to start by analyzing one of the standard pumping systems. The following facts, which Avery indicated were fairly typical, were to be used in the illustrative material: 1. The equipment has a delivered cost of $105,000. An additional $3,000 is required to install and test the new system. 2. The new pumping system is classified by the IRS as 5-year property, although it has an 8-year estimated service life. For assets classified by the IRS as 5-year property, the Modified Accelerated Cost Recovery System (MACRS) permits the company to depreciate the asset over 6 years at the following rates: Year 1 = 20 percent, Year 2 = 32 percent, Year 3 = 19 percent, Year 4 = 12 percent, Year 5 = 11 percent, Year 6 = 6 percent. At the end of 8 years, the salvage value is expected to be around 5 percent of the original purchase price, so the best estimate of salvage value at the end of the equipment's service life is $5,300, with removal costs of $1,200. 3. The existing pumping system was purchased at $45,000 eight years ago and has been depreciated on a straight-line basis over its economic life of 10 years. If the existing system is removed from the well and crated for pickup, it can be sold for $3,500 before tax. It will cost $1,000 to remove the system and crate it. 4. At the time of replacement, the firm will need to increase its net working capital requirements by $4,500 to support inventories. 5. The new pumping system offers lower maintenance costs and frees personnel who would otherwise have to monitor the system. In addition, it reduces product wastage because of a higher cooling efficiency. In total, it is estimated that the yearly savings will amount to $25,000 if the new pumping system is used. 6. The firm has its target debt ratio of 30 percent, and its cost of new debt is 10 percent. Its expected dividend per share next year, D1, is $2.00 with a future growth rate of 6 percent per year. The firm's current stock price, Po, is $40.00. The firm uses its overall weighted average cost of capital in evaluating average risk projects, and the replacement project is perceived to be of average risk. 7. The firm's federal-plus-state tax rate is 30 percent, and this rate is projected to remain fairly constant into the future. 1. Compute the firm's weighted average cost of capital given the info/data in the case. What other approaches/methods can be used to measure the firm's cost of equity and thus its WACC? To that end, what additional info/data would you need? (Hint: A firm's weighted average cost of capital is equal to Ka = W.(Ka)(1 - t) + W K, where We and We are the weights of debt and equity in the capital structure; Kd and Ke are the respective costs of debt and equity; and t is the corporate tax rate; Do no round up your WACC figure.) 2. Develop a capital budgeting schedule using the attached Cash Flow Estimation Worksheet (Excel spreadsheet) that should list all relevant cash flow items and amounts related to the replacement project over the 8-year expected life of the new pumping system. (Reference Reading: Cash Flow Analysis Example (RIC Project)", one of required Readings for the course.) 3. Based on the capital budgeting schedule, evaluate the replacement project by computing NV, IRR, MIRR, and Payback Period. Would you recommend to accept or reject the replacement project based solely on your DCF analysis so far? 4. Before you make the final accept/reject decision, what other factors and approaches would you consider further? Discuss also how to PRACTICALLY take into account those factors and approaches in the capital budgeting decision process, whenever FALCONVILLE PUMP COMPANY - CASH FLOW ESTIMATION WORK WORKSHEET Input Data Cost of NEW equipment Annual dep. of old equipment Salvage value new equipment OLD equipment's depreciable life left Coat of old equipment Olid equipment's depreciated years Depreciation of old equipment till dete Annal cost savings Salvage value of old equipment Removal cost of old equipment Tax rate Removal cost of new equipment WACC Networking capital requirement =0 =1 3 t=5 t=6 t=8 INVESTMENT OUTLAY 1 2 3 t=2 3 I 5 6 II OPERATING CASH FLOWS OVER THE PROJECT'S LIFE 7 8 9 10 11 12 III TERMINAL FEAR CASH FLOWS 13 14 15 16 17 IV NET CASH FLOWS 18 V RESULTS NPV IRR MIRR Payback period = DECISION BASED ON YOUR ANALYSIS: ANSWERS TO QUESTIONS: Q#1: Q#2: Q#3: Q#4

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts