Question: Answer please Dyer & Co. makes electronic components. Chris Dyer, the president, recently instructed Vice President Jim Bruegger to develop a total quality control program.

Answer please

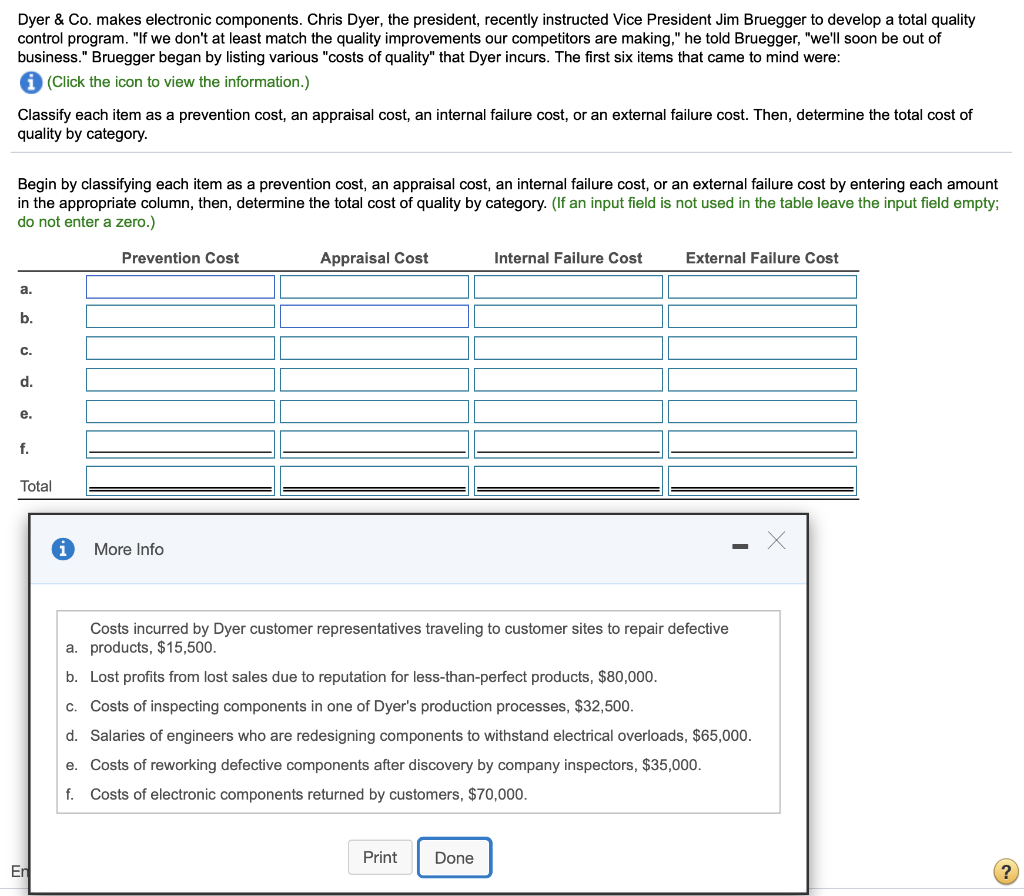

Dyer & Co. makes electronic components. Chris Dyer, the president, recently instructed Vice President Jim Bruegger to develop a total quality control program. "If we don't at least match the quality improvements our competitors are making," he told Bruegger, "we'll soon be out of business." Bruegger began by listing various "costs of quality" that Dyer incurs. The first six items that came to mind were: (Click the icon to view the information.) Classify each item as a prevention cost, an appraisal cost, an internal failure cost, or an external failure cost. Then, determine the total cost of quality by category. Begin by classifying each item as a prevention cost, an appraisal cost, an internal failure cost, or an external failure cost by entering each amount in the appropriate column, then, determine the total cost of quality by category. (If an input field is not used in the table leave the input field empty; do not enter a zero.) Prevention Cost Appraisal Cost Internal Failure Cost External Failure Cost a. b. c. d. e. f. Total More Info Costs incurred by Dyer customer representatives traveling to customer sites to repair defective a. products, $15,500. b. Lost profits from lost sales due to reputation for less-than-perfect products, $80,000. C. Costs of inspecting components in one of Dyer's production processes, $32,500. d. Salaries of engineers who are redesigning components to withstand electrical overloads, $65,000. e. Costs of reworking defective components after discovery by company inspectors, $35,000. f. Costs of electronic components returned by customers, $70,000. Print Done Done En

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts