Question: -Answer the following question with a multi-paragraph analytical response What are you asked to do? The case asks you to draw the CBP and identify

-Answer the following question with a multi-paragraph analytical response

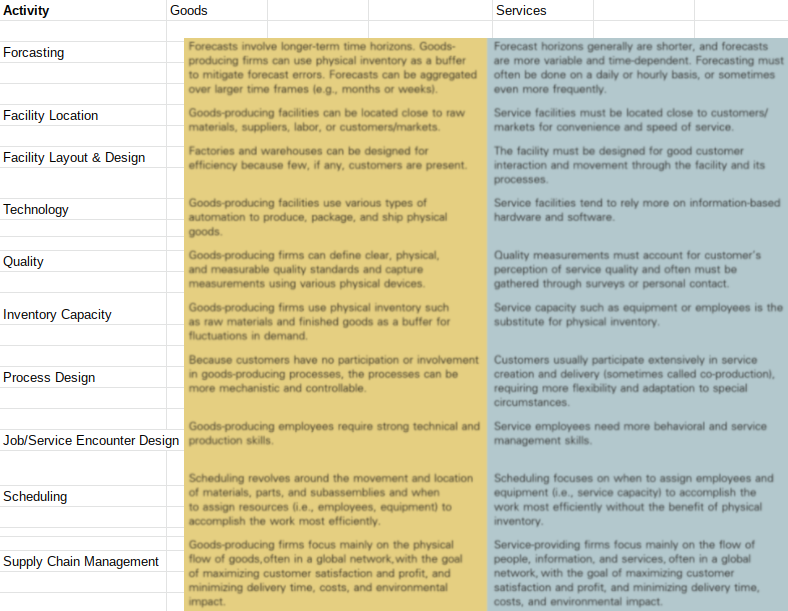

What are you asked to do? The case asks you to draw the CBP and identify one primary support, and general management process. You must also think about manufacturing/production encounters and service management skills. Finally, build a table like table below to begin to understand OM activities for the goods and services applied to Zappos business.

Zappos Zappas provides free shipping in both directions on all purchases. Zappos (www.zappos.com) is a Las Vegas-based on line retailer that has been cited in Fortune's list of the Best Companies to Work For and Fast Company's list of the world's most innovative companies. In fact, its remarkable success resulted in Zappos being bought by Amazon for $550 million in 2009. Zappos was founded in San Francisco in 1999 and moved to Las Vegas for the cheap real estate and abundant call center workers. The company sells a large variety of shoes from nearly every major manufacturer and has expanded its offerings to handbags, apparel, sunglasses, watches, and electronics Despite the crippling economic downturn, sales jumped almost 20 percent in 2005, passing the $1 billion mark two years ahead of schedule. The company's first core value is "Deliver WOW through service," which is obvious if you've ever ordered from Zappos. It provides free shipping in both directions on all purchases. It often gives customers surprise up grades for faster shipping. And it has a 365-day return policy. In 2003, Zappos made a decision about customer service: It views any expense that enhances the customer experience as a marketing cost because it generates more repeat customers through word of mouth. CEO Tony Hsieh never outsourced his call center because he considers the function too important to be sent to over seas. Job one for these frontliners is to delight callers. Unlike most inbound telemarketers, they don't work from a script. They're trained to encourage callers to or- der more than one size or color, because shipping is free in both directions, and to refer shoppers to competitors when a product is out of stock. Most important, though, they're implored to use their imaginations. This means that a customer having a tough day might find flowers on his or her doorstep the next morning. One Minnesota customer complained that her boots had begun leaking after almost a year of use. Not only did the Zappos cus tomer service representative send out a new pair-in spite of a policy that only unworn shoes are returnable- but she also told the customer to keep the old ones, and mailed a hand-written thank you." Over 95 percent of Zappo's transactions take place on the Web, so each ac tual customer phone call is a special opportunity. "They may only call once in their life, but that is our chance to wow them," Hsieh says. Zappos uses a sophisticated computer system known as Genghis to manage its operations. This in cludes an order entry, purchasing, warehouse manage- ment, inventory, shipping, and e-commerce system, Genghis tracks inventory so closely that customers can check online how many pairs of size 12 Clarks Desert boots are available in the color sand. For em- ployees, it automatically sends daily e-mail reminders to call a customer back, coordinates the warehouse ro- bot system, and produces reports that can specifically assess the impact on margins of putting a particular item on sale. Free shipping has become a customer expectation Research has found that online customers abandon their virtual shopping carts up to 75 percent of the time at the end of their order entry process when they can't get free shipping Other online retailers have copied the free shipping policies of Zappos. L.L. Bean, for exam- ple, now provides free shipping and free returns with no minimum order amount.

Activity Goods Services Forcasting Forecasts involve longer-term time horizons. Goods Forecast horizons generally are shorter, and forecasts producing firms can use physical inventory as a buffer are more variable and time-dependent. Forecasting must to mitigate forecast errors. Forecasts can be aggregated often be done on a daily or hourly basis, or sometimes over larger time frames (e.g., months or weeks). even more frequently Facility Location Goods producing facilities can be located close to raw Service facilities must be located close to customers/ materials, suppliers, labor, or customers/markets. markets for convenience and speed of service. Facility Layout & Design Factories and warehouses can be designed for The facility must be designed for good customer efficiency because few, if any, customers are present. interaction and movement through the facility and its processes Technology Goods producing facilities use various types of Service facilities tend to rely more on information-based automation to produce, package, and ship physical hardware and software. goods. Quality Goods producing firms can define clear, physical, Quality measurements must account for customer's and measurable quality standards and capture perception of service quality and often must be measurements using various physical devices gathered through surveys or personal contact Goods producing firms use physical inventory such Inventory Capacity Service capacity such as equipment or employees is the as raw materials and finished goods as a buffer for substitute for physical inventory fluctuations in demand. Because customers have no participation or involvement Customers usually participate extensively in service Process Design in goods producing processes, the processes can be creation and delivery (sometimes called co-production), more mechanistic and controllable. requiring more flexibility and adaptation to special circumstances Goods-producing employees require strong technical and Service employees need more behavioral and service Job/Service Encounter Design production skills management skills Scheduling Scheduling revolves around the movement and location of materials, parts, and subassemblies and when to assign resources (.e., employees, equipment to accomplish the work most efficiently. Goods producing firms focus mainly on the physical flow of goods, often in a global network with the goal of maximizing customer satisfaction and profit, and minimizing delivery time, costs, and environmental impact Scheduling focuses on when to assign employees and equipment 6.0., service capacity to accomplish the work most efficiently without the benefit of physical inventory Service providing firms focus mainly on the flow of people, information, and services, often in a global network, with the goal of maximizing customer satisfaction and profit, and minimizing delivery time, costs, and environmental impact. Supply Chain Management Activity Goods Services Forcasting Forecasts involve longer-term time horizons. Goods Forecast horizons generally are shorter, and forecasts producing firms can use physical inventory as a buffer are more variable and time-dependent. Forecasting must to mitigate forecast errors. Forecasts can be aggregated often be done on a daily or hourly basis, or sometimes over larger time frames (e.g., months or weeks). even more frequently Facility Location Goods producing facilities can be located close to raw Service facilities must be located close to customers/ materials, suppliers, labor, or customers/markets. markets for convenience and speed of service. Facility Layout & Design Factories and warehouses can be designed for The facility must be designed for good customer efficiency because few, if any, customers are present. interaction and movement through the facility and its processes Technology Goods producing facilities use various types of Service facilities tend to rely more on information-based automation to produce, package, and ship physical hardware and software. goods. Quality Goods producing firms can define clear, physical, Quality measurements must account for customer's and measurable quality standards and capture perception of service quality and often must be measurements using various physical devices gathered through surveys or personal contact Goods producing firms use physical inventory such Inventory Capacity Service capacity such as equipment or employees is the as raw materials and finished goods as a buffer for substitute for physical inventory fluctuations in demand. Because customers have no participation or involvement Customers usually participate extensively in service Process Design in goods producing processes, the processes can be creation and delivery (sometimes called co-production), more mechanistic and controllable. requiring more flexibility and adaptation to special circumstances Goods-producing employees require strong technical and Service employees need more behavioral and service Job/Service Encounter Design production skills management skills Scheduling Scheduling revolves around the movement and location of materials, parts, and subassemblies and when to assign resources (.e., employees, equipment to accomplish the work most efficiently. Goods producing firms focus mainly on the physical flow of goods, often in a global network with the goal of maximizing customer satisfaction and profit, and minimizing delivery time, costs, and environmental impact Scheduling focuses on when to assign employees and equipment 6.0., service capacity to accomplish the work most efficiently without the benefit of physical inventory Service providing firms focus mainly on the flow of people, information, and services, often in a global network, with the goal of maximizing customer satisfaction and profit, and minimizing delivery time, costs, and environmental impact. Supply Chain ManagementStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts