Question: ANSWER THE THIRD QUESTION 3. List the steps in the production process, beginning with purchasing ingredients, and ending with the sale, and state how quality

ANSWER THE THIRD QUESTION

3. List the steps in the production process, beginning with purchasing ingredients, and ending with the sale, and state how quality can be positively affected at each step.

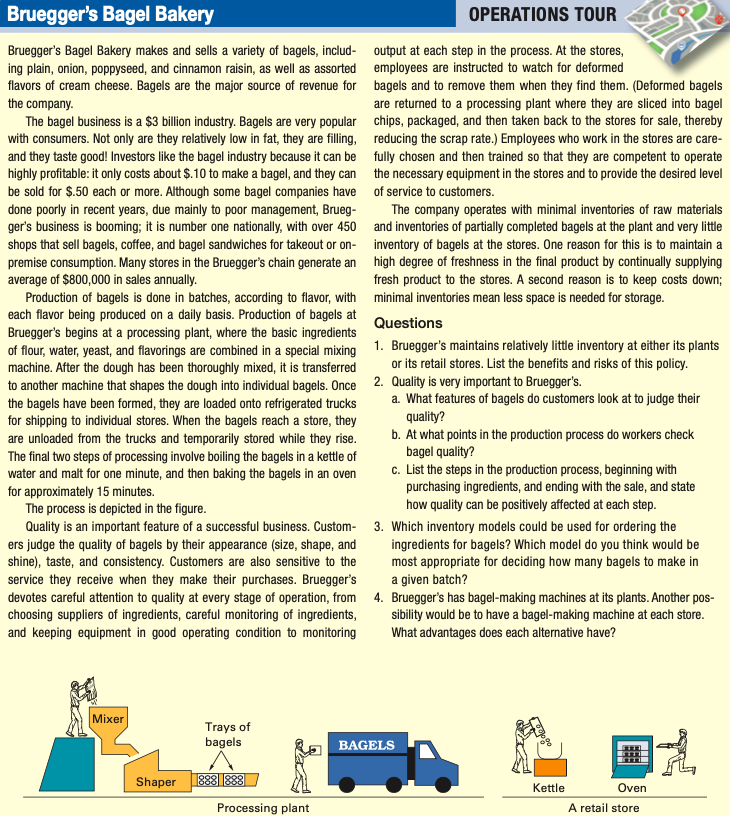

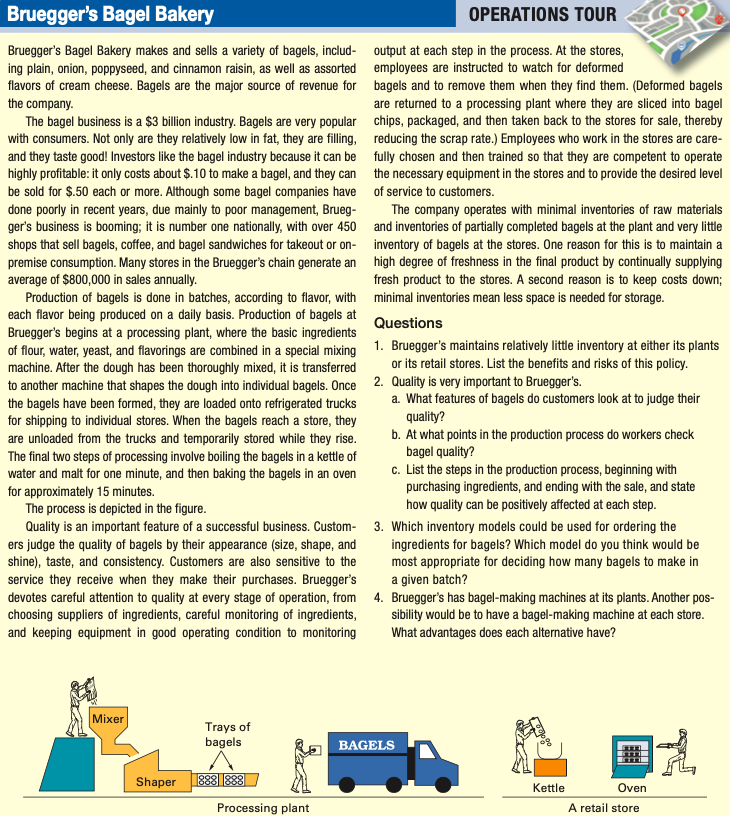

Bruegger's Bagel Bakery OPERATIONS TOUR Bruegger's Bagel Bakery makes and sells a variety of bagels, includ- output at each step in the process. At the stores, ing plain, onion, poppyseed, and cinnamon raisin, as well as assorted employees are instructed to watch for deformed flavors of cream cheese. Bagels are the major source of revenue for bagels and to remove them when they find them. (Deformed bagels the company. are returned to a processing plant where they are sliced into bagel The bagel business is a $3 billion industry. Bagels are very popular chips, packaged, and then taken back to the stores for sale, thereby with consumers. Not only are they relatively low in fat, they are filling, reducing the scrap rate.) Employees who work in the stores are care- and they taste good! Investors like the bagel industry because it can be fully chosen and then trained so that they are competent to operate highly profitable: it only costs about $.10 to make a bagel, and they can the necessary equipment in the stores and to provide the desired level be sold for $.50 each or more. Although some bagel companies have of service to customers. done poorly in recent years, due mainly to poor management, Brueg- The company operates with minimal inventories of raw materials ger's business is booming; it is number one nationally, with over 450 and inventories of partially completed bagels at the plant and very little shops that sell bagels, coffee, and bagel sandwiches for takeout or on- inventory of bagels at the stores. One reason for this is to maintain a premise consumption. Many stores in the Bruegger's chain generate an high degree of freshness in the final product by continually supplying average of $800,000 in sales annually. fresh product to the stores. A second reason is to keep costs down; Production of bagels is done in batches, according to flavor, with minimal inventories mean less space is needed for storage. each flavor being produced on a daily basis. Production of bagels at Questions Bruegger's begins at a processing plant, where the basic ingredients of flour, water, yeast, and flavorings are combined in a special mixing 1. Bruegger's maintains relatively little inventory at either its plants machine. After the dough has been thoroughly mixed, it is transferred or its retail stores. List the benefits and risks of this policy. to another machine that shapes the dough into individual bagels. Once 2. Quality is very important to Bruegger's. the bagels have been formed, they are loaded onto refrigerated trucks a What features of bagels do customers look at to judge their for shipping to individual stores. When the bagels reach a store, they quality? are unloaded from the trucks and temporarily stored while they rise. b. At what points in the production process do workers check The final two steps of processing involve boiling the bagels in a kettle of bagel quality? water and malt for one minute, and then baking the bagels in an oven c. List the steps in the production process, beginning with for approximately 15 minutes. purchasing ingredients, and ending with the sale, and state The process is depicted in the figure. how quality can be positively affected at each step. Quality is an important feature of a successful business. Custom- 3. Which inventory models could be used for ordering the ers judge the quality of bagels by their appearance (size, shape, and ingredients for bagels? Which model do you think would be shine), taste, and consistency. Customers are also sensitive to the most appropriate for deciding how many bagels to make in service they receive when they make their purchases. Bruegger's a given batch? devotes careful attention to quality at every stage of operation, from 4. Bruegger's has bagel-making machines at its plants. Another pos- choosing suppliers of ingredients, careful monitoring of ingredients, sibility would be to have a bagel-making machine at each store. and keeping equipment in good operating condition to monitoring What advantages does each alternative have? Mixer Trays of bagels BAGELS ILLE PA lif Shaper Kettle Oven A retail store Processing plant