Question: Answer the third question, I answered the first two. e CASE STUDY 10.1 Reliability: The Entire System In February 1965, Boeing began to produce the

Answer the third question, I answered the first two.

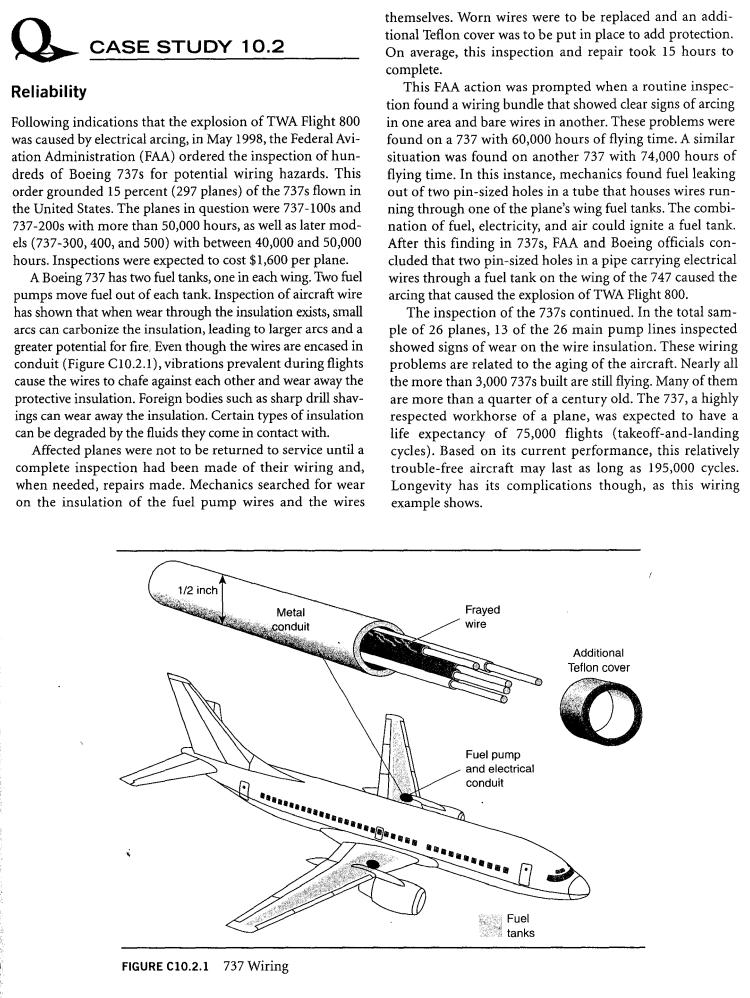

e CASE STUDY 10.1 Reliability: The Entire System In February 1965, Boeing began to produce the 737 twin- engine jet. This jet, a shorter version of the 707/727 with a more radically swept-back wing, filled a market need for a more fuel-efficient, no-frills aircraft. The smaller size of the 737 enables the jet to fly cost-effectively to smaller airports and more remote locations. In 1964, the original specifica- tions called for a plane with a capacity of between 60 and 85 passengers with an operating range of between 100 and 1,000 miles. Most importantly, the plane had to be able to break even economically with a 35 percent load factor. To- day's 737s carry 100 passengers with the range and load fac- tors remaining the same. Three decades and a few design and fuel-efficiency modifications later, the 737 continues to be manufactured. Over the years, it has become the best- selling aircraft ever built. At any one point in time, there are about 1,200 737s in the air. That means that a 737 takes off somewhere in the world every 5.3 seconds. The 737 fleet has flown about 124 million hours in service, traveling 49 bil- lion nautical miles or 90 billion kilometers. Of the 3,000 737s created, most are still flying, which means that many have lasted over a quarter of a century. When the 737 was originally conceived, engineers at Boeing predicted a life expectancy of 75,000 flights, or takeoff-and- landing cycles. Based on the behavior of the current planes still flying long after the predicted 75,000 flights, a Boeing 737 may last as long as 195,000 cycles (flights). Besides longevity, the 737 jets have the advantage of cockpit design and systems commonality with other Boeing jets. The Boeing 737 has wing-mounted engines that pro- vide less interference drag, a better center of gravity posi- tion, and more usable cabin space at the rear. From a reliability point of view, the wing-mounted engines allow better access to engines for maintenance and require less pipework for fuel. The weight of the engines also provides bending relief from the lift of the wings. The marked simi- larity in cockpit design has simplified pilot training. Cock- pit similarities allow pilots to transfer easily from cockpit to cockpit, and cockpit familiarity increases flight safety since in emergency situations pilots are not confused by control- surface differences. Cockpit and systems commonality provides the benefits of interchangeable parts, components, subassemblies, and subsystems. Maintenance is easier since repair people famil- iar with one plane can transfer that knowledge to another. Parts availability, and therefore aircraft availability, increases with interchangeable parts. The designers of the 737 kept reliability and cost in mind during the design phase. Much of the 727 design, particu- larly the fuselage cross section, is replicated in the 737. This gives cost savings in tooling commonality while providing nacelles, cockpit layout, avionics, components, and other fittings. Redundant and fail-safe systems are also a part of the Boeing 737. The plane has two engines but is able to fly with only one. The two engines support two electrical systems. Two fuel systems exist on the 737. If a loss of pressurization occurs on an aircraft, an emergency backup oxygen system exists. During its life, the 737 rudder has been redesigned to include three hydraulic rudder control devices instead of the original two. The added system provides better rudder con- trol in the event that one of the devices fails. All aircraft, whether private or commercial, maintain aircraft logs. In these logs, pilots record all flights and infor- mation pertaining to the length of flight, weather condi- tions, system failures, or repairs needed. The logs provide a record of routine maintenance, as well as information about loss of pressurization, turbine failure, engine overheat, false alarms with the warning lights, and other such failures. Extensive tests at Boeing and field-tested information from the 3,000 aircrafts' actual logs of flight experiences have been used to make system design changes, improve manufactur- ing methods, modify quality checks, and select the most reliable components. In an industry where 10 to 15 percent of the operating costs are devoted to maintenance, these aircraft are main- tained in such a manner that they will last indefinitely. Planes are systematically inspected, cleaned, repaired, rein- forced, rebolted, and resealed. This type of maintenance exceeds original factory standards and protects the planes from deterioration due to wear and tear and corrosion. However, as the planes age, the maintenance cost per flight hour increases significantly. The airline industry rule of thumb says that at the 25-year mark, a plane's maintenance will cost approximately double the maintenance costs asso- ciated with a new plane. The mean life of a jet engine is approximately 15,000 hours. Jet engines can be rebuilt, overhauled, or replaced to prolong the life of the entire jet. With the Boeing 737, pilots and mechanics have discovered that engine wear can be re- duced by decreasing the amount of engine thrust by 4 to 5 percent, enabling the engine to run 30 to 40 degrees cooler. Communication of this sort has resulted in significantly reduced engine wear and prolonged engine life. ASSIGNMENT Reliability programs have been used to prolong the lives of Boeing 737 airplanes. Using this chapter as a guide, describe the aspects of Boeing's reliability program. How did Boeing uses information about overall system reliability, communication maintenance, simplicity of design, humans in the system, redundant/fail-safe features, manufacturing methods, and maintenance records, etc., to improve the reliability of the 737? Then discuss the 737 in terms of the definition of CASE STUDY 10.2 Reliability Following indications that the explosion of TWA Flight 800 was caused by electrical arcing, in May 1998, the Federal Avi- ation Administration (FAA) ordered the inspection of hun- dreds of Boeing 737s for potential wiring hazards. This order grounded 15 percent (297 planes) of the 737s flown in the United States. The planes in question were 737-100s and 737-200s with more than 50,000 hours, as well as later mod- els (737-300, 400, and 500) with between 40,000 and 50,000 hours. Inspections were expected to cost $1,600 per plane. A Boeing 737 has two fuel tanks, one in each wing. Two fuel pumps move fuel out of each tank. Inspection of aircraft wire has shown that when wear through the insulation exists, small arcs can carbonize the insulation, leading to larger arcs and a greater potential for fire. Even though the wires are encased in conduit (Figure C10.2.1), vibrations prevalent during flights cause the wires to chafe against each other and wear away the protective insulation. Foreign bodies such as sharp drill shav- ings can wear away the insulation. Certain types of insulation can be degraded by the fluids they come in contact with. Affected planes were not to be returned to service until a complete inspection had been made of their wiring and, when needed, repairs made. Mechanics searched for wear on the insulation of the fuel pump wires and the wires themselves. Worn wires were to be replaced and an addi- tional Teflon cover was to be put in place to add protection. On average, this inspection and repair took 15 hours to complete. This FAA action was prompted when a routine inspec- tion found a wiring bundle that showed clear signs of arcing in one area and bare wires in another. These problems were found on a 737 with 60,000 hours of flying time. A similar situation was found on another 737 with 74,000 hours of flying time. In this instance, mechanics found fuel leaking out of two pin-sized holes in a tube that houses wires run- ning through one of the plane's wing fuel tanks. The combi- nation of fuel, electricity, and air could ignite a fuel tank. After this finding in 737s, FAA and Boeing officials con- cluded that two pin-sized holes in a pipe carrying electrical wires through a fuel tank on the wing of the 747 caused the arcing that caused the explosion of TWA Flight 800. The inspection of the 737s continued. In the total sam- ple of 26 planes, 13 of the 26 main pump lines inspected showed signs of wear on the wire insulation. These wiring problems are related to the aging of the aircraft. Nearly all the more than 3,000 737s built are still flying. Many of them are more than a quarter of a century old. The 737, a highly respected workhorse of a plane, was expected to have a life expectancy of 75,000 flights (takeoff-and-landing cycles). Based on its current performance, this relatively trouble-free aircraft may last as long as 195,000 cycles. Longevity has its complications though, as this wiring example shows. 1/2 inch Metal Frayed wire conduit Additional Teflon cover Fuel pump and electrical conduit Fuel tanks FIGURE C10.2.1 737 Wiring ASSIGNMENT The remaining planes showed no signs of failure when the test was terminated at 75,000 hours. The average time to inspect and/or repair any of the planes was 15 hours. CASE STUDY BIBLIOGRAPHY Investigate this 1998 incident with the Boeing 747 and 737 aircraft. If we consider the long life of the 737 aircraft, what reliability considerations might have been overlooked during the design, construction, or use of the 737s? In other words, what could have been done differently to improve the 737 aircraft reliability? Boeing recommends a life span of 20 years, 60,000 hours, and 20,000 flight cycles for a 747. What do they recommend for a 737? ASSIGNMENT Adcock, S. FAA Orders Fix on Older 737s. Newsday, May 8, 1998. Field, D. FAA Grounds Oldest 737's." USA Today, May 11, 1998. Field, D. "Order Causes Little Turbulence." USA Today, May 11, 1998. "Improving Airliner Reliability." SWE, November/December 1995. McMarthy, M. No. 19603 Still Flies After 27 Years' Service to a Number of Airlines." Wall Street Journal, August 9, 1995. Redesign Ordered for 737 Rudders." USA Today, September 14, 2000. U.S. FAA: FAA Orders Immediate Inspection for High-time Boeing 737s, Extends Inspection Order, M2." Press WIRE, May 11, 1998 Calculate the mean life and availability associated with the 26 airplanes sampled. Use the information provided as well as the following assumptions: A failure is considered to be any sign of worn wiring or insulation. Of the 13 failures, one occurred at 60,000 hours, the sec- ond at 74,000 hours, and the remainder at 50,000 hours. e CASE STUDY 10.1 Reliability: The Entire System In February 1965, Boeing began to produce the 737 twin- engine jet. This jet, a shorter version of the 707/727 with a more radically swept-back wing, filled a market need for a more fuel-efficient, no-frills aircraft. The smaller size of the 737 enables the jet to fly cost-effectively to smaller airports and more remote locations. In 1964, the original specifica- tions called for a plane with a capacity of between 60 and 85 passengers with an operating range of between 100 and 1,000 miles. Most importantly, the plane had to be able to break even economically with a 35 percent load factor. To- day's 737s carry 100 passengers with the range and load fac- tors remaining the same. Three decades and a few design and fuel-efficiency modifications later, the 737 continues to be manufactured. Over the years, it has become the best- selling aircraft ever built. At any one point in time, there are about 1,200 737s in the air. That means that a 737 takes off somewhere in the world every 5.3 seconds. The 737 fleet has flown about 124 million hours in service, traveling 49 bil- lion nautical miles or 90 billion kilometers. Of the 3,000 737s created, most are still flying, which means that many have lasted over a quarter of a century. When the 737 was originally conceived, engineers at Boeing predicted a life expectancy of 75,000 flights, or takeoff-and- landing cycles. Based on the behavior of the current planes still flying long after the predicted 75,000 flights, a Boeing 737 may last as long as 195,000 cycles (flights). Besides longevity, the 737 jets have the advantage of cockpit design and systems commonality with other Boeing jets. The Boeing 737 has wing-mounted engines that pro- vide less interference drag, a better center of gravity posi- tion, and more usable cabin space at the rear. From a reliability point of view, the wing-mounted engines allow better access to engines for maintenance and require less pipework for fuel. The weight of the engines also provides bending relief from the lift of the wings. The marked simi- larity in cockpit design has simplified pilot training. Cock- pit similarities allow pilots to transfer easily from cockpit to cockpit, and cockpit familiarity increases flight safety since in emergency situations pilots are not confused by control- surface differences. Cockpit and systems commonality provides the benefits of interchangeable parts, components, subassemblies, and subsystems. Maintenance is easier since repair people famil- iar with one plane can transfer that knowledge to another. Parts availability, and therefore aircraft availability, increases with interchangeable parts. The designers of the 737 kept reliability and cost in mind during the design phase. Much of the 727 design, particu- larly the fuselage cross section, is replicated in the 737. This gives cost savings in tooling commonality while providing nacelles, cockpit layout, avionics, components, and other fittings. Redundant and fail-safe systems are also a part of the Boeing 737. The plane has two engines but is able to fly with only one. The two engines support two electrical systems. Two fuel systems exist on the 737. If a loss of pressurization occurs on an aircraft, an emergency backup oxygen system exists. During its life, the 737 rudder has been redesigned to include three hydraulic rudder control devices instead of the original two. The added system provides better rudder con- trol in the event that one of the devices fails. All aircraft, whether private or commercial, maintain aircraft logs. In these logs, pilots record all flights and infor- mation pertaining to the length of flight, weather condi- tions, system failures, or repairs needed. The logs provide a record of routine maintenance, as well as information about loss of pressurization, turbine failure, engine overheat, false alarms with the warning lights, and other such failures. Extensive tests at Boeing and field-tested information from the 3,000 aircrafts' actual logs of flight experiences have been used to make system design changes, improve manufactur- ing methods, modify quality checks, and select the most reliable components. In an industry where 10 to 15 percent of the operating costs are devoted to maintenance, these aircraft are main- tained in such a manner that they will last indefinitely. Planes are systematically inspected, cleaned, repaired, rein- forced, rebolted, and resealed. This type of maintenance exceeds original factory standards and protects the planes from deterioration due to wear and tear and corrosion. However, as the planes age, the maintenance cost per flight hour increases significantly. The airline industry rule of thumb says that at the 25-year mark, a plane's maintenance will cost approximately double the maintenance costs asso- ciated with a new plane. The mean life of a jet engine is approximately 15,000 hours. Jet engines can be rebuilt, overhauled, or replaced to prolong the life of the entire jet. With the Boeing 737, pilots and mechanics have discovered that engine wear can be re- duced by decreasing the amount of engine thrust by 4 to 5 percent, enabling the engine to run 30 to 40 degrees cooler. Communication of this sort has resulted in significantly reduced engine wear and prolonged engine life. ASSIGNMENT Reliability programs have been used to prolong the lives of Boeing 737 airplanes. Using this chapter as a guide, describe the aspects of Boeing's reliability program. How did Boeing uses information about overall system reliability, communication maintenance, simplicity of design, humans in the system, redundant/fail-safe features, manufacturing methods, and maintenance records, etc., to improve the reliability of the 737? Then discuss the 737 in terms of the definition of CASE STUDY 10.2 Reliability Following indications that the explosion of TWA Flight 800 was caused by electrical arcing, in May 1998, the Federal Avi- ation Administration (FAA) ordered the inspection of hun- dreds of Boeing 737s for potential wiring hazards. This order grounded 15 percent (297 planes) of the 737s flown in the United States. The planes in question were 737-100s and 737-200s with more than 50,000 hours, as well as later mod- els (737-300, 400, and 500) with between 40,000 and 50,000 hours. Inspections were expected to cost $1,600 per plane. A Boeing 737 has two fuel tanks, one in each wing. Two fuel pumps move fuel out of each tank. Inspection of aircraft wire has shown that when wear through the insulation exists, small arcs can carbonize the insulation, leading to larger arcs and a greater potential for fire. Even though the wires are encased in conduit (Figure C10.2.1), vibrations prevalent during flights cause the wires to chafe against each other and wear away the protective insulation. Foreign bodies such as sharp drill shav- ings can wear away the insulation. Certain types of insulation can be degraded by the fluids they come in contact with. Affected planes were not to be returned to service until a complete inspection had been made of their wiring and, when needed, repairs made. Mechanics searched for wear on the insulation of the fuel pump wires and the wires themselves. Worn wires were to be replaced and an addi- tional Teflon cover was to be put in place to add protection. On average, this inspection and repair took 15 hours to complete. This FAA action was prompted when a routine inspec- tion found a wiring bundle that showed clear signs of arcing in one area and bare wires in another. These problems were found on a 737 with 60,000 hours of flying time. A similar situation was found on another 737 with 74,000 hours of flying time. In this instance, mechanics found fuel leaking out of two pin-sized holes in a tube that houses wires run- ning through one of the plane's wing fuel tanks. The combi- nation of fuel, electricity, and air could ignite a fuel tank. After this finding in 737s, FAA and Boeing officials con- cluded that two pin-sized holes in a pipe carrying electrical wires through a fuel tank on the wing of the 747 caused the arcing that caused the explosion of TWA Flight 800. The inspection of the 737s continued. In the total sam- ple of 26 planes, 13 of the 26 main pump lines inspected showed signs of wear on the wire insulation. These wiring problems are related to the aging of the aircraft. Nearly all the more than 3,000 737s built are still flying. Many of them are more than a quarter of a century old. The 737, a highly respected workhorse of a plane, was expected to have a life expectancy of 75,000 flights (takeoff-and-landing cycles). Based on its current performance, this relatively trouble-free aircraft may last as long as 195,000 cycles. Longevity has its complications though, as this wiring example shows. 1/2 inch Metal Frayed wire conduit Additional Teflon cover Fuel pump and electrical conduit Fuel tanks FIGURE C10.2.1 737 Wiring ASSIGNMENT The remaining planes showed no signs of failure when the test was terminated at 75,000 hours. The average time to inspect and/or repair any of the planes was 15 hours. CASE STUDY BIBLIOGRAPHY Investigate this 1998 incident with the Boeing 747 and 737 aircraft. If we consider the long life of the 737 aircraft, what reliability considerations might have been overlooked during the design, construction, or use of the 737s? In other words, what could have been done differently to improve the 737 aircraft reliability? Boeing recommends a life span of 20 years, 60,000 hours, and 20,000 flight cycles for a 747. What do they recommend for a 737? ASSIGNMENT Adcock, S. FAA Orders Fix on Older 737s. Newsday, May 8, 1998. Field, D. FAA Grounds Oldest 737's." USA Today, May 11, 1998. Field, D. "Order Causes Little Turbulence." USA Today, May 11, 1998. "Improving Airliner Reliability." SWE, November/December 1995. McMarthy, M. No. 19603 Still Flies After 27 Years' Service to a Number of Airlines." Wall Street Journal, August 9, 1995. Redesign Ordered for 737 Rudders." USA Today, September 14, 2000. U.S. FAA: FAA Orders Immediate Inspection for High-time Boeing 737s, Extends Inspection Order, M2." Press WIRE, May 11, 1998 Calculate the mean life and availability associated with the 26 airplanes sampled. Use the information provided as well as the following assumptions: A failure is considered to be any sign of worn wiring or insulation. Of the 13 failures, one occurred at 60,000 hours, the sec- ond at 74,000 hours, and the remainder at 50,000 hoursStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock