Question: Appendix 1 1 A Economic Order Quantity Objective Derive the economic order quantity ( EOQ ) formula. Analysis: Given an annual demand D , order

Appendix A

Economic Order Quantity

Objective

Derive the economic order quantity EOQ formula.

Analysis:

Given an annual demand order cost unit cost and annual holding cost our goal is to estimate the lot size that minimizes the total annual cost. For a lot size of the total annual cost is given by

Total annual cost,

To minimize the total cost, we take the first derivative with respect to the lot size and set it to zero. Taking the first derivative with respect to we have

Setting the first derivative to be zero, the EOQ is given by

DShCorQ

A

Case Study Moon Chem.pdf

Case Study

Delivery Strategy at MoonChem

John Kresge, vice president of supply chain, was very concerned as he left the meeting at MoonChem, a manufacturer of specialty chemicals. The yearend meeting evaluated financial performance and discussed the fact that the firm was achieving only two inventory turns a year. A more careful look revealed that more than half the inventory MoonChem owned was in consignment with its customers. This was very surprising, given that only percent of its customers carried consignment inventory. John was responsible for inventory as well as transportation costs. He decided to take a careful look at the management of consignment inventory and come up with an appropriate plan.

MoonChem Operations

MoonChem, a manufacturer of specialty chemicals, had eight manufacturing plants and distribution centers. The plants manufactured the base chemicals, and the distribution centers mixed them to produce hundreds of end products that fit customer specifications. In the specialty chemicals market, MoonChem decided to differentiate itself in the Midwest region by providing consignment inventory to its customers. The company wanted to take this strategy national if it proved effective. MoonChem kept the chemicals required by each customer in the Midwest region on consignment at the customers' sites. Customers used the chemicals as needed, and MoonChem managed replenishment to ensure availability. In most instances, consumption of chemicals by customers was stable.

:

A

Case Study Moon Chem.pdf

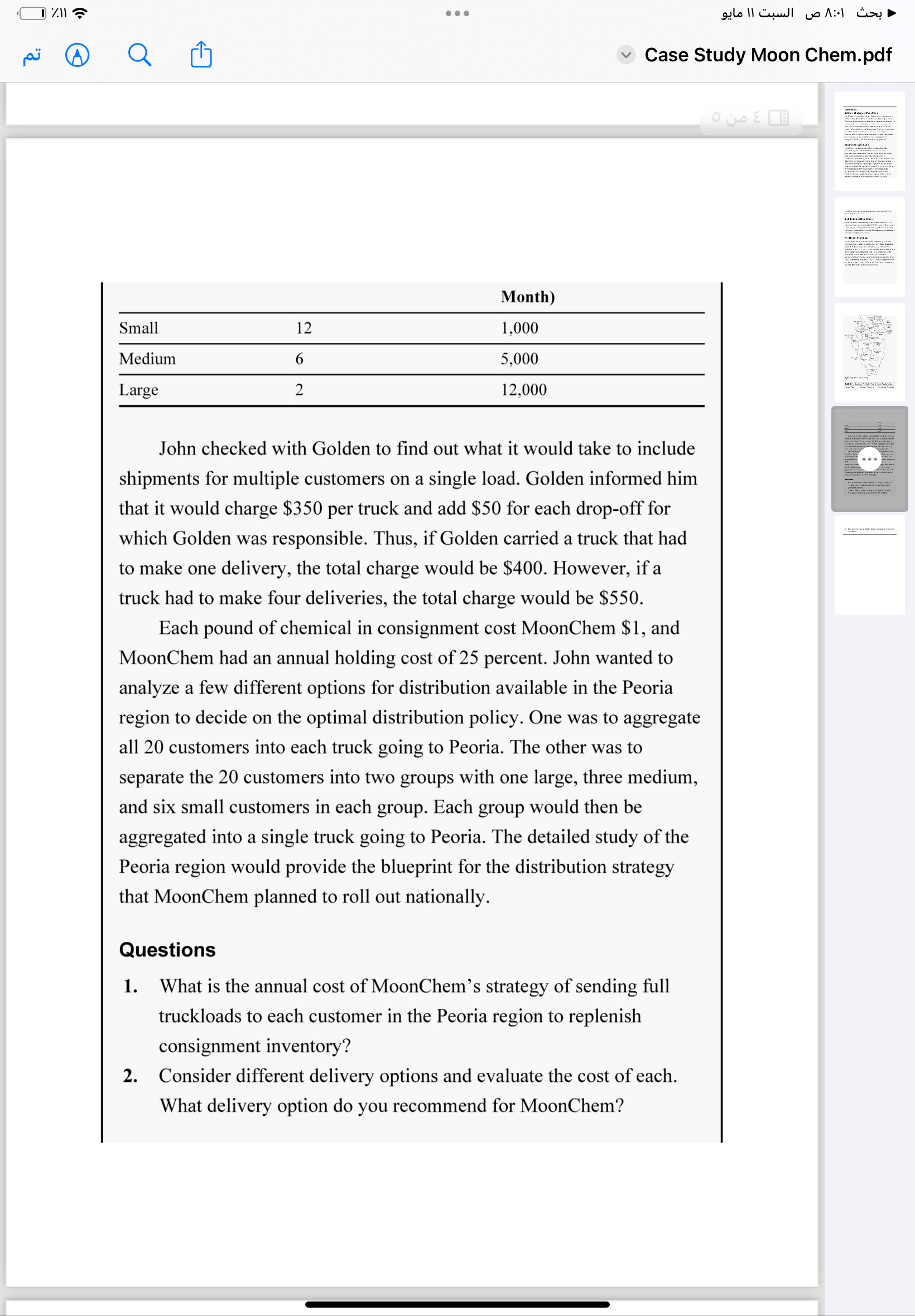

Table Customer Profile for MoonChem in Peoria Region

Customer Type

Number of Customers

Consumption Pounds per

Case Study Moon Chem.pdf

tableMonthSmallMediumLarge

John checked with Golden to find out what it would take to include shipments for multiple customers on a single load. Golden informed him that it would charge $ per truck and add $ for each dropoff for which Golden was responsible. Thus, if Golden carried a truck that had to make one delivery, the total charge would be $ However, if a truck had to make four deliveries, the total charge would be $

Each pound of chemical in consignment cost MoonChem $ and MoonChem had an annual holding cost of percent. John wanted to analyze a few different options for distribution available in the Peoria region to decide on the optimal distribution policy. One was to aggregate all customers into each truck going to Peoria. The other was to separate the customers into two groups with one large, three medium, and six small customers in each group. Each group would then be aggregated into a single truck going to Peoria. The detailed study of the Peoria region would provide the blueprint for the distribution strategy that MoonChem planned to roll out nationally.

Questions

What is the annual cost of MoonChem's strategy of sending full truckloads to each customer in the Peoria region to replenish consignment inventory?

Consider different delivery options and evaluate the cost of each. What delivery option do you recommend for MoonChem?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock