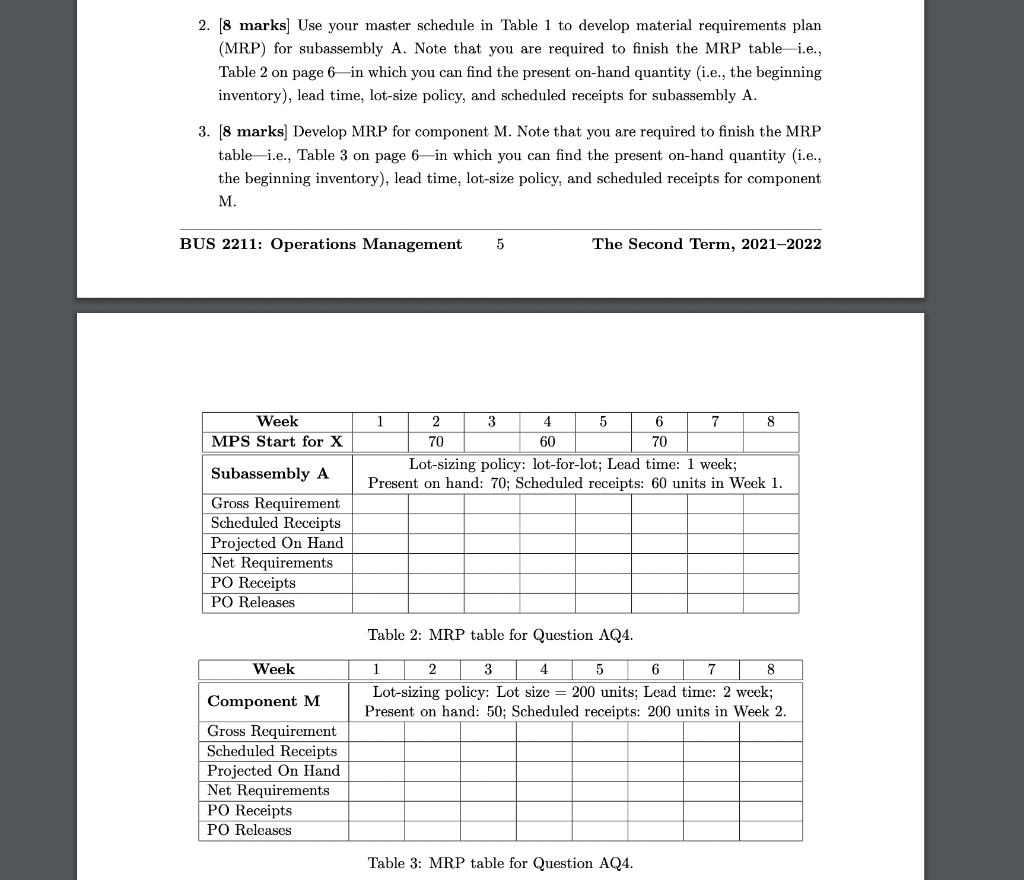

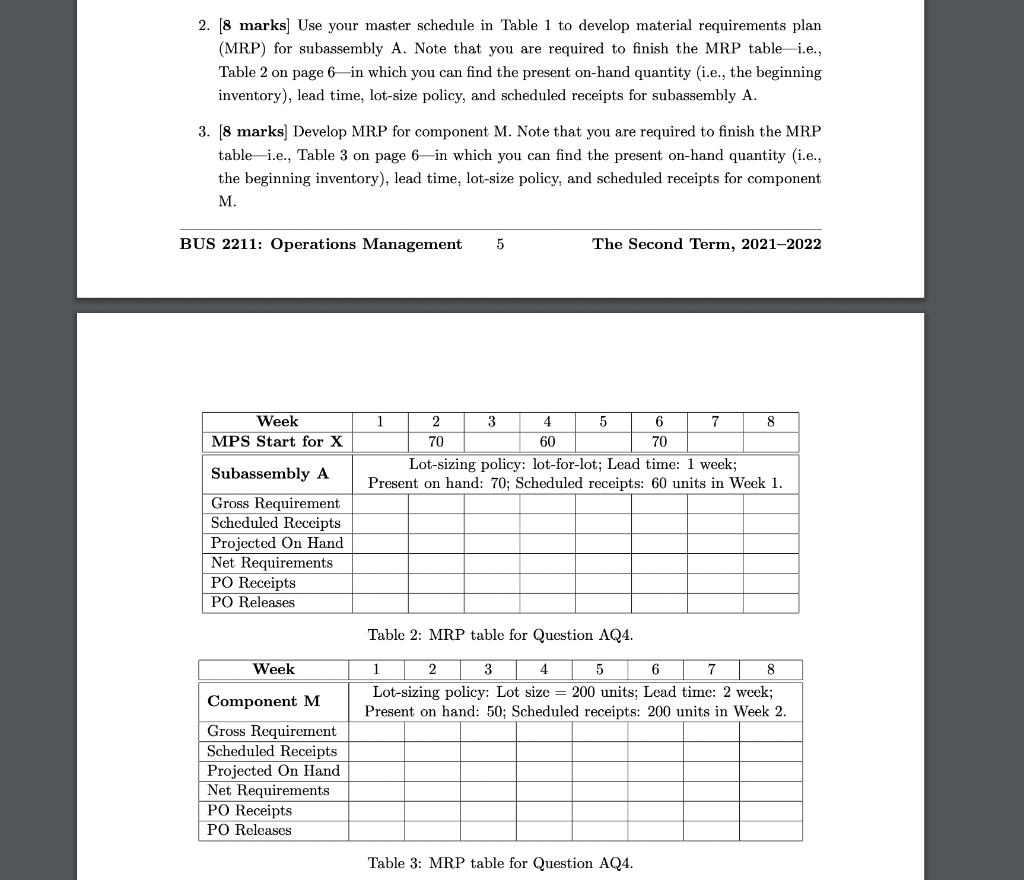

AQ4. MPS and MRP [30 marks) A firm assembles two final products X and Y, following the bill of materials in Figure 1. The X Y A(2) B(1) M(3) P(2) M(2) N(3) Figure 1: Bill of materials used for Question AQ4. assembly schedule (i.e., the master production schedule or MPS) for final product Y is as follows: 1 7 8 Week MPS Start for Y 2 3 4 20 0 20 5 6 40 0 0 20 20 1. [10 marks) You are required to fill in Table 1 to prepare a master schedule for product X. Each time when the firm assembles the product, the firm always uses the fired period of two rule to make X. The firm's assembly time for product X is 1 week. The beginning inventory for X is 82 units; the forecast and promised customer orders for this final product are provided in Table 1. 8 7 30 40 0 2 Week 0 1 2 3 5 6 Forecast 30 40 40 40 30 30 Customer orders (committed) 28 42 30 22 10 5 Projected on-hand inventory Net inventory before MPS MPS Receipt MPS Start Available-to-promise inventory (uncommitted) Table 1: MPS table for final product X in Question AQ4. 2. [8 marks] Use your master schedule in Table 1 to develop material requirements plan (MRP) for subassembly A. Note that you are required to finish the MRP table i.e., Table 2 on page 6-in which you can find the present on-hand quantity (i.e., the beginning inventory), lead time, lot-size policy, and scheduled receipts for subassembly A. 3. (8 marks) Develop MRP for component M. Note that you are required to finish the MRP tablei.e., Table 3 on page 6-in which you can find the present on-hand quantity (i.e., the beginning inventory), lead time, lot-size policy, and scheduled receipts for component M. BUS 2211: Operations Management 5 The Second Term, 2021-2022 3 6 Week MPS Start for X 1 2 5 7 8 70 60 70 Lot-sizing policy: lot-for-lot; Lead time: 1 week; Present on hand: 70; Scheduled receipts: 60 units in Week 1. Subassembly A Gross Requirement Scheduled Receipts Projected On Hand Net Requirements PO Receipts PO Releases Table 2: MRP table for Question AQ4. Week 6 1 2 3 4 5 7 8 Lot-sizing policy: Lot size = 200 units; Lead time: 2 week; Present on hand: 50; Scheduled receipts: 200 units in Week 2. Component M Gross Requirement Scheduled Receipts Projected On Hand Net Requirements PO Receipts PO Releases Table 3: MRP table for Question AQ4. AQ4. MPS and MRP [30 marks) A firm assembles two final products X and Y, following the bill of materials in Figure 1. The X Y A(2) B(1) M(3) P(2) M(2) N(3) Figure 1: Bill of materials used for Question AQ4. assembly schedule (i.e., the master production schedule or MPS) for final product Y is as follows: 1 7 8 Week MPS Start for Y 2 3 4 20 0 20 5 6 40 0 0 20 20 1. [10 marks) You are required to fill in Table 1 to prepare a master schedule for product X. Each time when the firm assembles the product, the firm always uses the fired period of two rule to make X. The firm's assembly time for product X is 1 week. The beginning inventory for X is 82 units; the forecast and promised customer orders for this final product are provided in Table 1. 8 7 30 40 0 2 Week 0 1 2 3 5 6 Forecast 30 40 40 40 30 30 Customer orders (committed) 28 42 30 22 10 5 Projected on-hand inventory Net inventory before MPS MPS Receipt MPS Start Available-to-promise inventory (uncommitted) Table 1: MPS table for final product X in Question AQ4. 2. [8 marks] Use your master schedule in Table 1 to develop material requirements plan (MRP) for subassembly A. Note that you are required to finish the MRP table i.e., Table 2 on page 6-in which you can find the present on-hand quantity (i.e., the beginning inventory), lead time, lot-size policy, and scheduled receipts for subassembly A. 3. (8 marks) Develop MRP for component M. Note that you are required to finish the MRP tablei.e., Table 3 on page 6-in which you can find the present on-hand quantity (i.e., the beginning inventory), lead time, lot-size policy, and scheduled receipts for component M. BUS 2211: Operations Management 5 The Second Term, 2021-2022 3 6 Week MPS Start for X 1 2 5 7 8 70 60 70 Lot-sizing policy: lot-for-lot; Lead time: 1 week; Present on hand: 70; Scheduled receipts: 60 units in Week 1. Subassembly A Gross Requirement Scheduled Receipts Projected On Hand Net Requirements PO Receipts PO Releases Table 2: MRP table for Question AQ4. Week 6 1 2 3 4 5 7 8 Lot-sizing policy: Lot size = 200 units; Lead time: 2 week; Present on hand: 50; Scheduled receipts: 200 units in Week 2. Component M Gross Requirement Scheduled Receipts Projected On Hand Net Requirements PO Receipts PO Releases Table 3: MRP table for Question AQ4