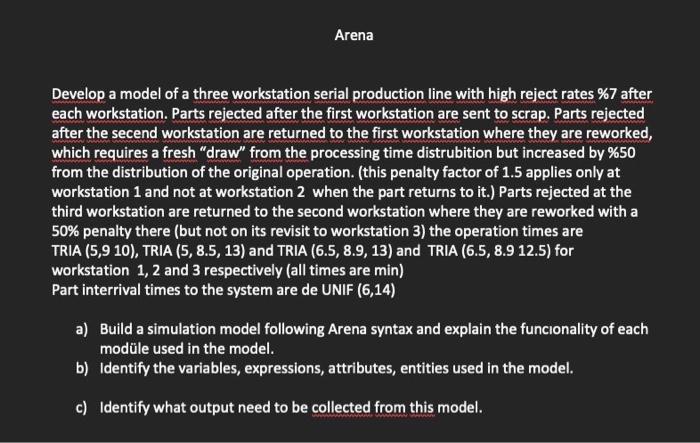

Question: Arena Develop a model of a three workstation serial production line with high reject rates %7 after each workstation. Parts rejected after the first workstation

Arena Develop a model of a three workstation serial production line with high reject rates %7 after each workstation. Parts rejected after the first workstation are sent to scrap. Parts rejected after the secend workstation are returned to the first workstation where they are reworked, which requires a fresh "draw" from the processing time distrubition but increased by %50 from the distribution of the original operation. (this penalty factor of 1.5 applies only at workstation 1 and not at workstation 2 when the part returns to it.) Parts rejected at the third workstation are returned to the second workstation where they are reworked with a 50% penalty there (but not on its revisit to workstation 3 ) the operation times are TRIA (5,910), TRIA (5,8.5,13) and TRIA (6.5,8.9,13) and TRIA (6.5,8.912.5) for workstation 1,2 and 3 respectively (all times are min) Part interrival times to the system are de UNIF (6,14) a) Build a simulation model following Arena syntax and explain the funcionality of each modle used in the model. b) Identify the variables, expressions, attributes, entities used in the model. c) Identify what output need to be collected from this model

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts