Question: As a Reliability Engineer, you have been hired to work on the optimization of an automotive assembly line (see figure below). Aware of the flaws

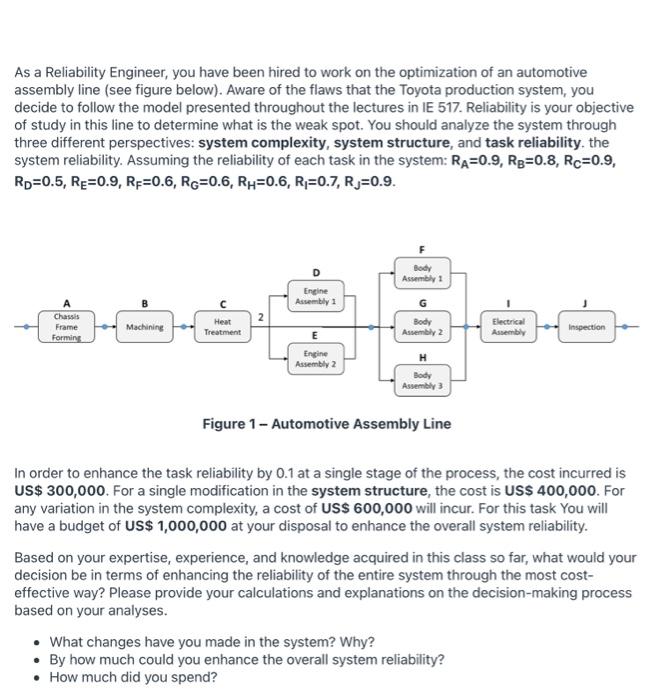

As a Reliability Engineer, you have been hired to work on the optimization of an automotive assembly line (see figure below). Aware of the flaws that the Toyota production system, you decide to follow the model presented throughout the lectures in IE 517. Reliability is your objective of study in this line to determine what is the weak spot. You should analyze the system through three different perspectives: system complexity, system structure, and task reliability, the system reliability. Assuming the reliability of each task in the system: RA=0.9, Rg=0.8, Rc=0.9, Rp=0.5, Re=0.9, Rp=0.6, RG=0.6, RH=0.6, R=0.7, R=0.9. Body Assembly Engine Assembly 1 2 Body Chassis Frame Forming Machining Heat Treatment Electrical Assembly Inspection Assembly 2 Engine Assembly 2 H Body Assembly 3 Figure 1 - Automotive Assembly Line In order to enhance the task reliability by 0.1 at a single stage of the process, the cost incurred is US$ 300,000. For a single modification in the system structure, the cost is US$ 400,000. For any variation in the system complexity, a cost of US$ 600,000 will incur. For this task You will have a budget of US$ 1,000,000 at your disposal to enhance the overall system reliability. Based on your expertise, experience, and knowledge acquired in this class so far, what would your decision be in terms of enhancing the reliability of the entire system through the most cost- effective way? Please provide your calculations and explanations on the decision-making process based on your analyses. What changes have you made in the system? Why? By how much could you enhance the overall system reliability? How much did you spend? As a Reliability Engineer, you have been hired to work on the optimization of an automotive assembly line (see figure below). Aware of the flaws that the Toyota production system, you decide to follow the model presented throughout the lectures in IE 517. Reliability is your objective of study in this line to determine what is the weak spot. You should analyze the system through three different perspectives: system complexity, system structure, and task reliability, the system reliability. Assuming the reliability of each task in the system: RA=0.9, Rg=0.8, Rc=0.9, Rp=0.5, Re=0.9, Rp=0.6, RG=0.6, RH=0.6, R=0.7, R=0.9. Body Assembly Engine Assembly 1 2 Body Chassis Frame Forming Machining Heat Treatment Electrical Assembly Inspection Assembly 2 Engine Assembly 2 H Body Assembly 3 Figure 1 - Automotive Assembly Line In order to enhance the task reliability by 0.1 at a single stage of the process, the cost incurred is US$ 300,000. For a single modification in the system structure, the cost is US$ 400,000. For any variation in the system complexity, a cost of US$ 600,000 will incur. For this task You will have a budget of US$ 1,000,000 at your disposal to enhance the overall system reliability. Based on your expertise, experience, and knowledge acquired in this class so far, what would your decision be in terms of enhancing the reliability of the entire system through the most cost- effective way? Please provide your calculations and explanations on the decision-making process based on your analyses. What changes have you made in the system? Why? By how much could you enhance the overall system reliability? How much did you spend

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts