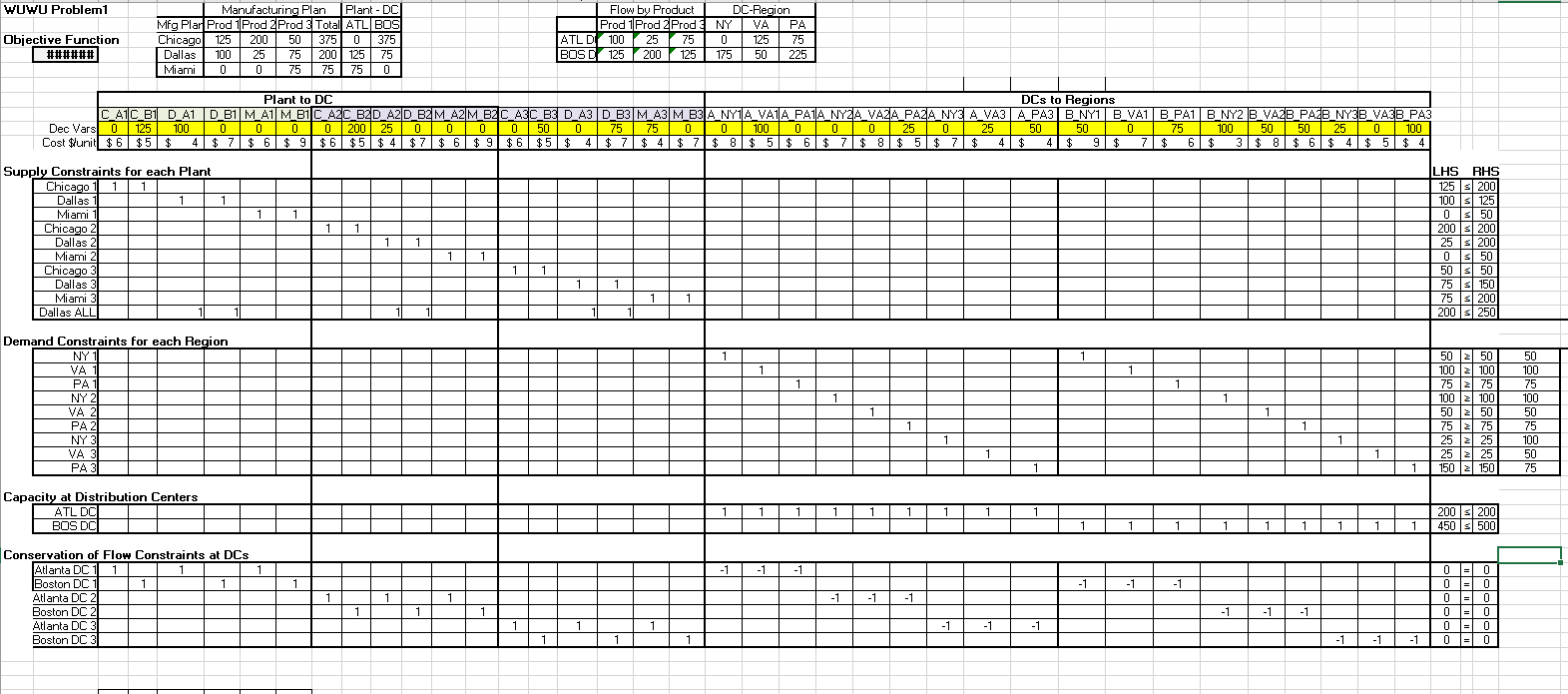

Question: As it stands now, the objective function for WUWU1 problem has an optimal value of $6,525.00. Try solving for the problem in its current form:

As it stands now, the objective function for WUWU1 problem has an optimal value of $6,525.00. Try solving for the problem in its current form: you should get the same value. The questions below will ask you to modify the parameters of this model, and the model itself, to include new constraints and products.

Q1: For the first variation of the problem, we will change the capacity in both our DCs. Please increase the capacity of the Atlanta DC from 200 widgets to 300 widgets, and decrease the capacity of the Boston DC from 500 widgets to 400 widgets. Solve optimally. What is the new minimum cost of the optimal solution? Ans: 6250

Q2: For the second variation, we will build upon Q1 and add a new constraint to the problem: the Miami plant will now have an overall capacity constraint of 250 widgets of any type. Calculate the new minimum cost solution. Compare this new cost to the one in Q1. Did the new constraint that we just added to the problem make any difference in the solution? Ans: No

Q3: For the third variation, we will build upon Q2 and add a new constraint to the problem: the Chicago plant will now have an overall capacity constraint of 250 widgets of any type. Solve optimally. What is the new minimum cost of the optimal solution? Rounding your answers to the nearest integer.

Q4: The fourth variation builds upon Q3 and adds two new constraints. First, we add a 150 widget capacity constraint at the Atlanta DC specific to widget 1. In other words, the Atlanta DC can process at most 150 units of widget 1. Second, we add a similar constraint for the the Boston DC specific to widget 2: the Boston DC can now handle at most 200 units of widget 2. What is the new minimum cost of the optimal solution?

Q5: The fifth and last variation builds upon Q4 and adds a new commodity to the portfolio: Widget 4. Demand in the regions for Widget 4 are as follows: 20 units in NY 20 units in VA 10 units in PA Production capacity for Widget 4 in the different plants is as follows: Up to 20 in Chicago Up to 40 in Dallas Up to 25 in Miami For Widget 4, the transportation costs from plants to DCs are: 6 from Chicago to Atlanta 5 from Chicago to Boston 4 from Dallas to Atlanta 7 from Dallas to Boston 5 from Miami to Atlanta 8 from Miami to Boston For Widget 4, the transportation costs from DC to regions are: 8 from Atlanta to NY 6 from Atlanta to VA 6 from Atlanta to PA 5 from Boston to NY 6 from Boston to VA 5 from Boston to PA.

What is the new minimum cost of the optimal solution?

WUWU Problem1 Manufacturing Plan | Plant - DC Flow by Product DC-Region Ifg Plar Prod 1 Prod 2 Prod 3 Total ATL BOS Prod 1 Prod 2 Prod 3 NY VA PA Objective Function Chicago 125 200 50 375 0 375 ATL DI 100 25 0 125 75 ### # # # Dallas 100 25 75 200 125 75 BOS C 125 200 125 175 50 Miami 0 0 75 75 75 0 Plant to DC DCs to Regions C AIC B1 D A1 D B1 M A1 M BIC AZC BZD A2D BZM A2M BEC ASC BE D A3 D B3 M A3 M B3A NY1A VATA PATA NYZA VAZA PAZA NYE A VA3 A PA3 B NY1 B VAT B PAT B NY2 B VAZB PAZB NYEB VAEB PA3 Dec Vars 0 125 100 0 0 0 0 200 25 0 0 0 0 50 0 75 75 0 0 100 0 0 25 0 25 50 50 75 100 50 50 25 0 100 Cost $unit $6 $5 $ 4 $ 7 $ 6 $ 9 $6 $5 $4 $7 $ 6 $9 $6 $5 $ 4 $ 7 $ 4 $ 7 $ 8 $ 5 $ 6 $ 7 $ 8 $ 5 $ 7 $ 4 $ 4 $ 9 4 7 $ 6 $ 3 $ 8 $ 6 $ 4 $ 5 $4 Supply Constraints for each Plant LHS RHS Chicago 1 125 6 200 Dallas 100 3 125 Miami 1 0 8 50 Chicago 2 200 3 200 Dallas 2 25 5 200 Miami 2 0 8 50 Chicago 3 50 8 50 Dallas 3 75 5 150 Miami 3 75 5 200 Dallas ALL 200 3 250 Demand Constraints for each Region NY VA 1 PA 1 NY 2 100 2 100 VA 2 50 2 50 50 PA 2 75 2 75 75 NY 3 100 VA 3 25 2 25 50 PA 3 150 2 150 75 Capacity at Distribution Centers ATL DO 200 5 200 BOS DC] 450 3 500 Conservation of Flow Constraints at DCs Atlanta DC 1 Boston DC 1 0 = 0 Atlanta DC 2 0 0 Boston DC 2 10 Atlanta DC 3 -1 0 Boston DC 3 0 = 0

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts