Question: As mentioned in Section 2.2 (Deen), polymeric additives can greatly reduce the resistance in turbulent pipe flow. That is manifested by a decrease in f

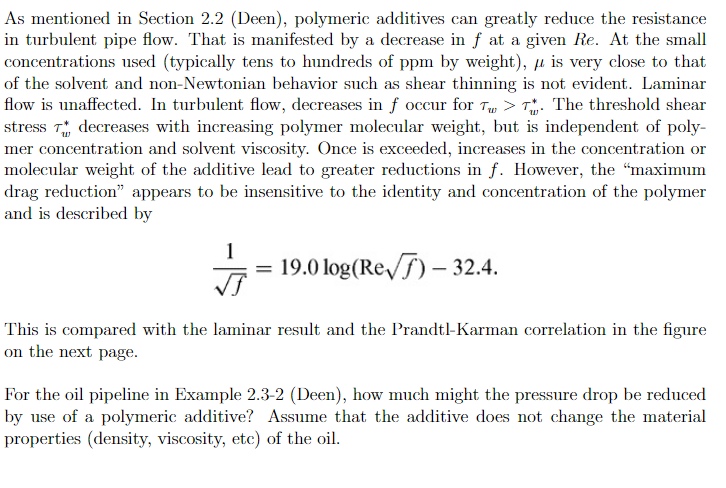

As mentioned in Section 2.2 (Deen), polymeric additives can greatly reduce the resistance in turbulent pipe flow. That is manifested by a decrease in f at a given Re. At the small concentrations used (typically tens to hundreds of ppm by weight), u is very close to that of the solvent and non-Newtonian behavior such as shear thinning is not evident. Laminar flow is unaffected. In turbulent flow, decreases in f occur for Ty > The threshold shear stress the decreases with increasing polymer molecular weight, but is independent of poly- mer concentration and solvent viscosity. Once is exceeded, increases in the concentration or molecular weight of the additive lead to greater reductions in f. However, the maximum drag reduction" appears to be insensitive to the identity and concentration of the polymer and is described by 1 = 19.0 log(Re) 32.4. This is compared with the laminar result and the Prandtl-Karman correlation in the figure on the next page. For the oil pipeline in Example 2.3-2 (Deen), how much might the pressure drop be reduced by use of a polymeric additive? Assume that the additive does not change the material properties (density, viscosity, etc) of the oil. As mentioned in Section 2.2 (Deen), polymeric additives can greatly reduce the resistance in turbulent pipe flow. That is manifested by a decrease in f at a given Re. At the small concentrations used (typically tens to hundreds of ppm by weight), u is very close to that of the solvent and non-Newtonian behavior such as shear thinning is not evident. Laminar flow is unaffected. In turbulent flow, decreases in f occur for Ty > The threshold shear stress the decreases with increasing polymer molecular weight, but is independent of poly- mer concentration and solvent viscosity. Once is exceeded, increases in the concentration or molecular weight of the additive lead to greater reductions in f. However, the maximum drag reduction" appears to be insensitive to the identity and concentration of the polymer and is described by 1 = 19.0 log(Re) 32.4. This is compared with the laminar result and the Prandtl-Karman correlation in the figure on the next page. For the oil pipeline in Example 2.3-2 (Deen), how much might the pressure drop be reduced by use of a polymeric additive? Assume that the additive does not change the material properties (density, viscosity, etc) of the oil

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts