Question: Assembly Department 1 5 machine hours Required: Question Content Area 1 . Complete the following table by calculating the sawmill's cost per board for each

Assembly Department machine hours Required: Question Content Area Complete the following table by calculating the sawmill's cost per board for each grade using both the physical units method and the salesvalueatsplitoff method. Begin by allocating the joint manufacturing costs to each grade, and calculate the cost per board foot for each grade using each method. Round unit cost answers to two decimal places. a Physical units method of allocation: Grades Allocation Unit Cost Firsts and seconds $fill in the blank $fill in the blank No common fill in the blank eaded fill in the blank eaded No common fill in the blank eaded fill in the blank eaded No common fill in the blank eaded fill in the blank eaded Totals $fill in the blank eaded Salesvalueatsplitoff method: Grades Allocation Unit Cost Firsts and seconds $fill in the blank No common fill in the blank fill in the blank eaded No common fill in the blank fill in the blank eaded No common fill in the blank eaded fill in the blank eaded Total $fill in the blank eaded Sawmill Cost and Production Data Grade Physical Units Method: Cost per Board Foot SalesValueatSplitOff Method: Cost per Board Foot Firsts and seconds $fill in the blank eaded $fill in the blank eaded No common fill in the blank eaded fill in the blank eaded No common fill in the blank eaded fill in the blank eaded No common fill in the blank eaded fill in the blank eaded b Given that the sawmill provides lumber at cost to the furniture plant, using the salesvalueatsplitoff method increases the cost of Job A by $fill in the blank eaded and increases the cost of Job B by $fill in the blank eaded c The physical units method, often used in the lumber industry, essentially assumes that it costs the same to produce each board foot regardless of the grade. Thus, the same cost of lumber would be assigned to a sofa or chair regardless of which grade is used. This approach has some drawbacks. Intuitively, the higher grades should cost more Certainly, if the company was buying this input from suppliers, there would be a cost difference for sofas and chairs depending on the grade of lumber purchased, because the higher grades have a higher selling price. The relative sales value method assigns a higher cost to grades that have a higher market value. Thus, the cost assigned to sofas and chairs would differ according to the grade of lumber used. d Review the data analytic concepts and metrics found in Exhibits and pp What are the data analytic models being considered for the Sawmill? Physical units method Which of the data analytic types is being used in Part a of Requirement Descriptive And for Part b Diagnostic and Predictive Part c Descriptive Note: More than one data analytic type may apply. Which of the data analytic models in play would you recommend for assigning the joint manufacturing sawmill costs? Descriptive, Diagnostic and Predictive Calculate the plantwide overhead rate for the fabric plant. $fill in the blank eaded per hour Calculate the amount of under or overapplied overhead for the fabric plant. $fill in the blank eaded overapplied a Using the weighted average method, complete the following information regarding the Weaving and Pattern production process: i Physical flow schedule measured in yards fill in the blank eaded ii Materials fill in the blank eaded Conversion Costs fill in the blank eaded iii. Unit cost $fill in the blank eaded iv Cost of goods transferred out $fill in the blank eaded b To convert the output of the Weaving and Pattern Department to the output of the Coloring and Bolting Department, yards transferred is divided by fill in the blank eaded c Using the weighted average method, complete the following for the Coloring and Bolting Department: i Physical flow schedule measured in bolts fill in the blank eaded Transferredin Materials Mater

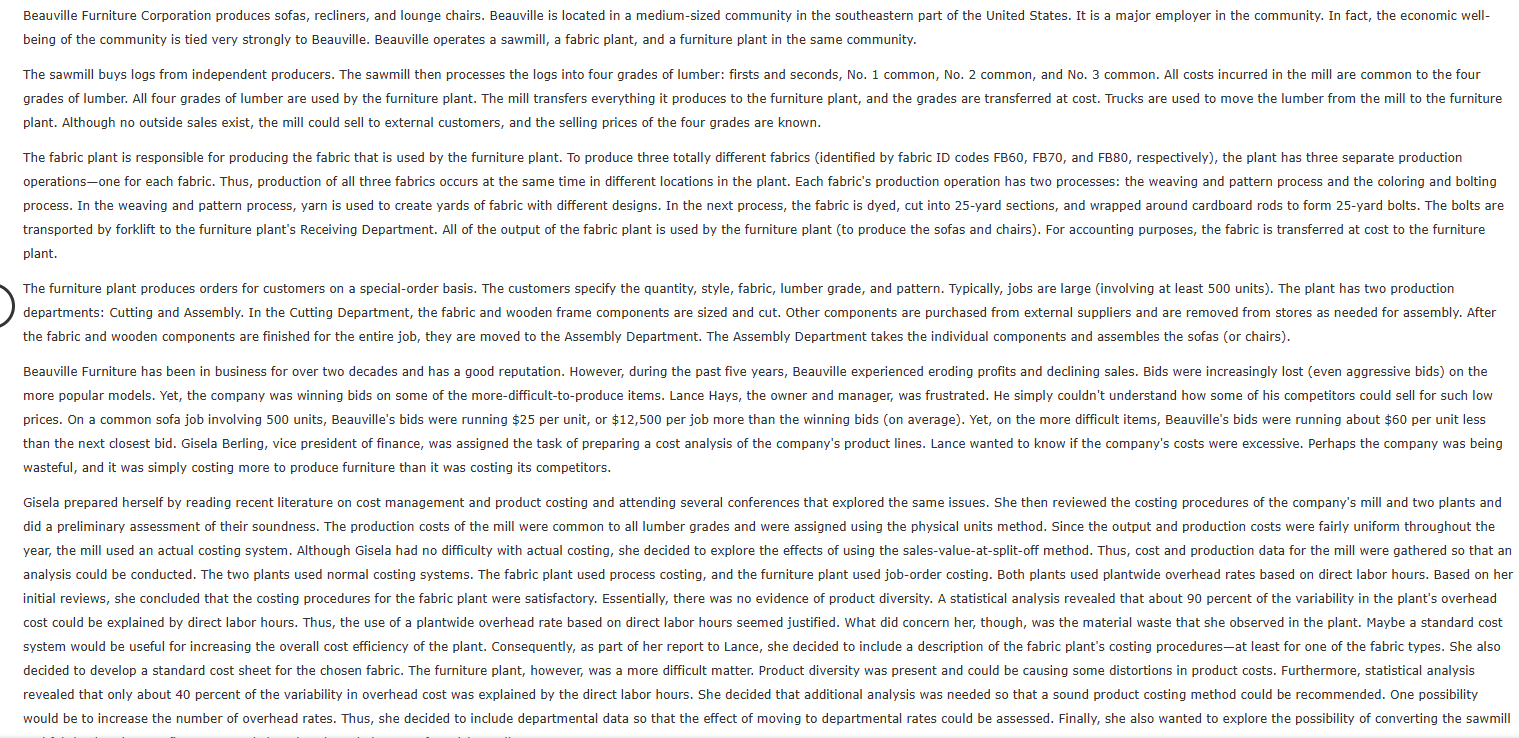

being of the community is tied ver

Sawmill:

Joint manufacturing costs: $

Fabric Plant:

Budgeted overhead: $ fixed

Practical volume direct labor hours: hours

Actual overhead: $ fixed

Actual hours worked:

Departmental data on Fabric FBactual costs and actual outcomes:

Pattern

Bolting

process. The cost of the rods is relatively ins

pr

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock