Question: Assembly - Line Design and Balancing Step 1 : Identify tasks and immediate predecessors in the assembly line process. Step 2 : Determine output rate

AssemblyLine Design and Balancing

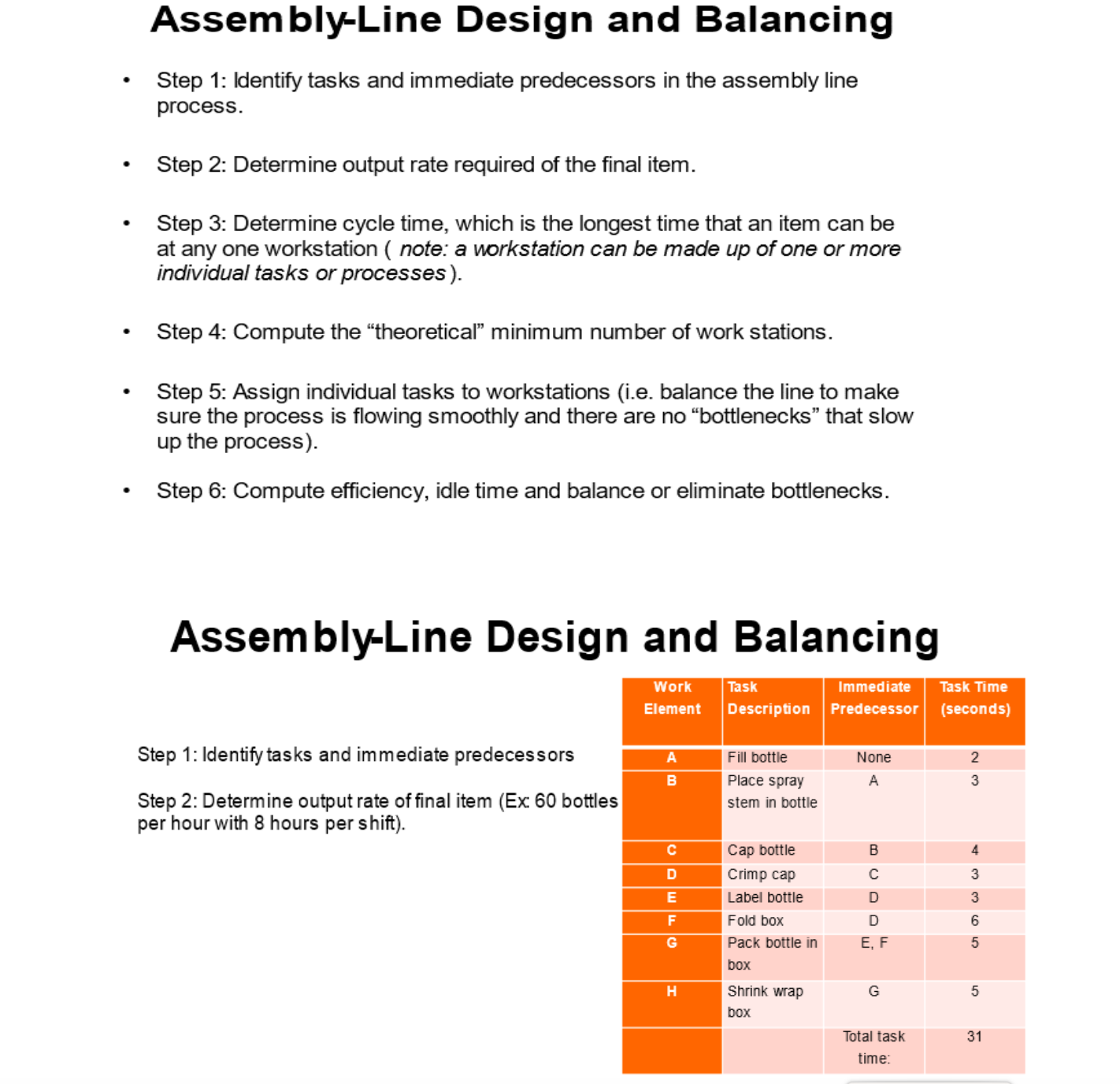

Step : Identify tasks and immediate predecessors in the assembly line

process.

Step : Determine output rate required of the final item.

Step : Determine cycle time, which is the longest time that an item can be

at any one workstation note: a workstation can be made up of one or more

individual tasks or processes

Step : Compute the "theoretical" minimum number of work stations.

Step : Assign individual tasks to workstations ie balance the line to make

sure the process is flowing smoothly and there are no "bottlenecks" that slow

up the process

Step : Compute efficiency, idle time and balance or eliminate bottlenecks.

AssemblyLine Design and Balancing

Step : Identify tasks and immediate predecessors

Step : Determine output rate of final item Ex bottles

per hour with hours per shift

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock