Question: Assessment 2 : Process Flowsheet Synthesis In this assessment, you are to synthesize a process flowsheet and determine process conditions by utilizing appropriate chemical engineering

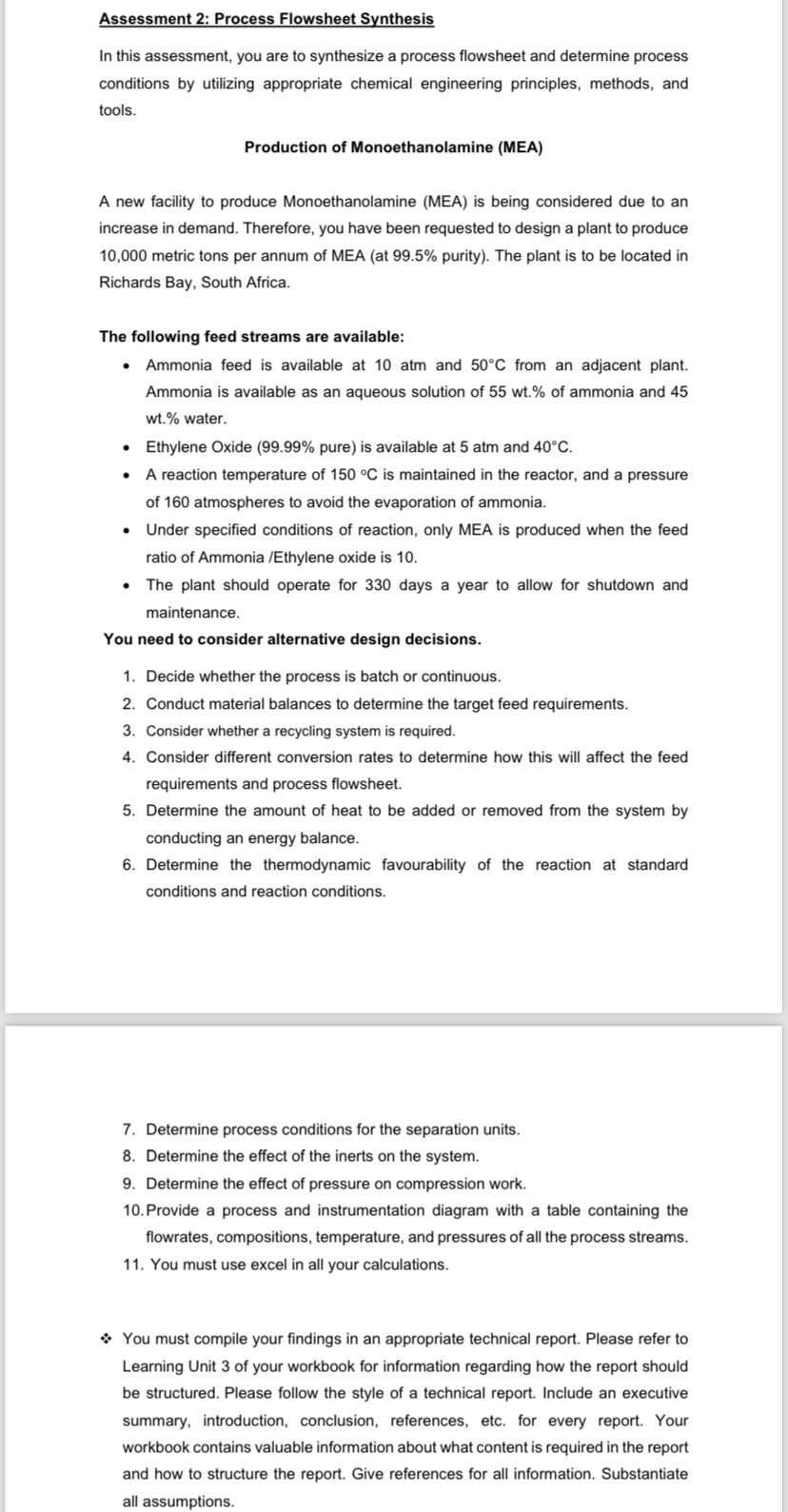

Assessment : Process Flowsheet Synthesis

In this assessment, you are to synthesize a process flowsheet and determine process conditions by utilizing appropriate chemical engineering principles, methods, and tools.

Production of Monoethanolamine MEA

A new facility to produce Monoethanolamine MEA is being considered due to an increase in demand. Therefore, you have been requested to design a plant to produce metric tons per annum of MEA at purity The plant is to be located in Richards Bay, South Africa.

The following feed streams are available:

Ammonia feed is available at atm and from an adjacent plant. Ammonia is available as an aqueous solution of of ammonia and wt water.

Ethylene Oxide pure is available at atm and

A reaction temperature of is maintained in the reactor, and a pressure of atmospheres to avoid the evaporation of ammonia.

Under specified conditions of reaction, only MEA is produced when the feed ratio of Ammonia Ethylene oxide is

The plant should operate for days a year to allow for shutdown and maintenance.

You need to consider alternative design decisions.

Decide whether the process is batch or continuous.

Conduct material balances to determine the target feed requirements.

Consider whether a recycling system is required.

Consider different conversion rates to determine how this will affect the feed requirements and process flowsheet.

Determine the amount of heat to be added or removed from the system by conducting an energy balance.

Determine the thermodynamic favourability of the reaction at standard conditions and reaction conditions.

Determine process conditions for the separation units.

Determine the effect of the inerts on the system.

Determine the effect of pressure on compression work.

Provide a process and instrumentation diagram with a table containing the flowrates, compositions, temperature, and pressures of all the process streams.

You must use excel in all your calculations.

You must compile your findings in an appropriate technical report. Please refer to Learning Unit of your workbook for information regarding how the report should be structured. Please follow the style of a technical report. Include an executive summary, introduction, conclusion, references, etc. for every report. Your workbook contains valuable information about what content is required in the report and how to structure the report. Give references for all information. Substantiate all assumptions.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock