Question: Assignment # 2 OPM 4 0 0 Due Nov. 2 6 , 2 0 2 3 1 1 : 5 9 pm ABC Interiors, Toronto,

Assignment # OPM Due Nov. :pm

ABC Interiors, Toronto, ON

ABC Interiors. is a leading North American automotive seating supplier and manufacturer to several automotive manufacturers in Canada, committed to continuously optimizing seat manufacturing costs as well as constantly exceeding quality expectations for all of their customers.

All seats are manufactured to the specifications provided by the individual automotive customer. They currently supply Honda, General Motors and Ford Motor Company.

Recently, customers have advised that the number of defects has risen to unacceptable levels. ABC Interiors. needs to reduce defects immediately because this could jeopardize customer relationships as well as causing the need to replace defective seats, increasing material waste and total costs.

As a result, ABC Interiors has added an extra inspection step at the end of the process with two inspectors who carefully check all aspects of each seat before being loaded onto the truck for shipping. Although this adds cost, it was felt that this was an urgent, temporary step until problems are solved. Although necessary, the cost of added multiple inspections are having an adverse impact on the bottom line.

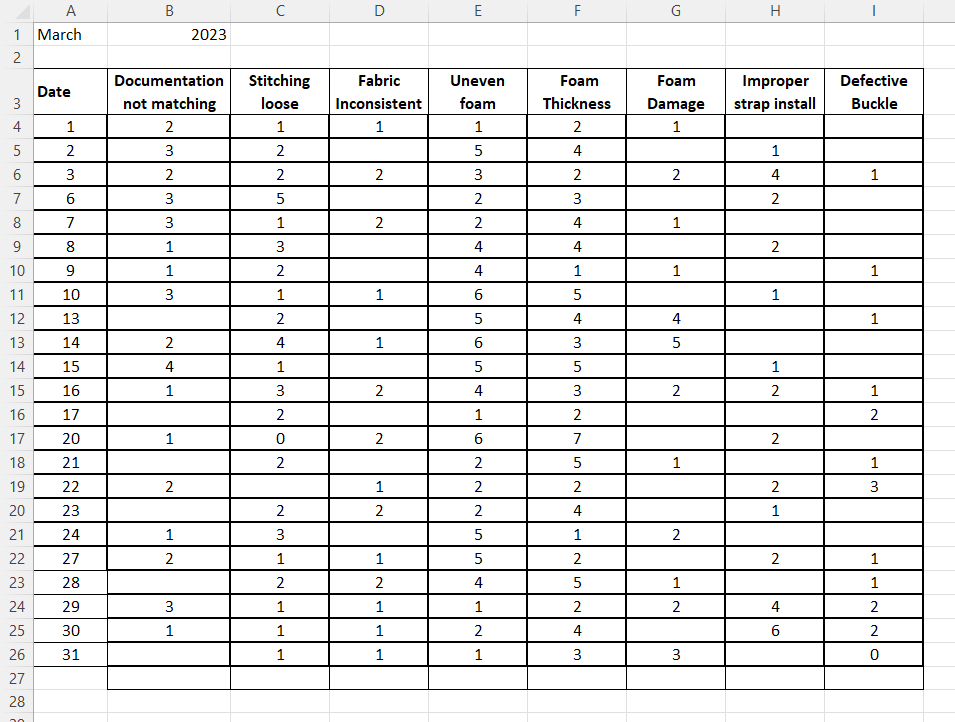

As a new hire from Seneca College, you have been asked to review and analyze the quality data recorded by the new inspection operation. You have been provided with the defect data shown in the next tab and also have observed the following during the evaluation process.

All the components fabric foam, straps, coils, buckles, threads are purchased in bulk, ready to assemble into seats. Suppliers are from a variety of countries.

With the recent addition of a new contract last month, additional employees were hired to operate some of the equipment.

One new machine was added within the last month to increase capacity. Some feel that this machine is contributing to defects.

There was some opinion that many of the defects are created first thing in the morning, and also right after the lunch break.

Recently, an additional fabric supplier was brought on for some seats.

When inspectors identify a defect, they notify supervisors who need to act quickly to have repairs completed or remake the item to ensure that is goes on the truck with the rest of the order. This can cause dangerous delays and jeopardizes ontime delivery to the customer. It also upsets the operation with last minute rushing for these exceptions. March Complete the following in the "Your Answer" tab below:

Create a PARETO TABLE and GRAPH using the reject data from March Marks

Create a RUN CHART line chart for each of the top three Defects in your Pareto Analysis. THREE charts needed Your goal is to look for and comment on any patterns or relationships. The dates belong on the X axis and the number of rejects on the Y axis. Note that the data was collected Mon Friday during March. Marks

Prepare a Fishbone Diagram indicating the reasons that might be contributing to the errors. Be sure to include a minimum of three points on each line. Marks

The management team has considered the possibility of implementing Total Quality Management into this facility. In ONE paragraph, discuss how TQM could assist ABC Interiors to increase the quality of their products. Use a TEXT box. Marks

Using information from this assignment and the topics learned IN THIS CLASS, give your specific THREE main recommendations to ABC Interiors Group for them to improve their quality. Use a TEXT BOX and list your recommendations as # # # Use only your course materials and ebook as references. Marks

Please note that prior to submitting any assignment to me that you check the print ranges of the documentspreadsheet I expect that the spreadsheet will print inside the paraeters of an X paper and all graphs are complete ie not spread over two pages. This can be accomplished by:

a Checking the print range

b Adjusting the margins to minimums of custom margins

c Look a Scaling as an option

Why? Because many managers will print a document given to them as they go into a meeting so they have a hard copy to reference. If you don't set the print ranges and parameters properly, your page document may print as pages that are completely disjointed. Also by setting the parameters in the orginal document, it will print CORRECTLY, every time. This is a good habit to get into!

How do you check? Print the document and check it on your own screen prior to sending. If you fail to do this....I will deduct marks from the mark attained.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock