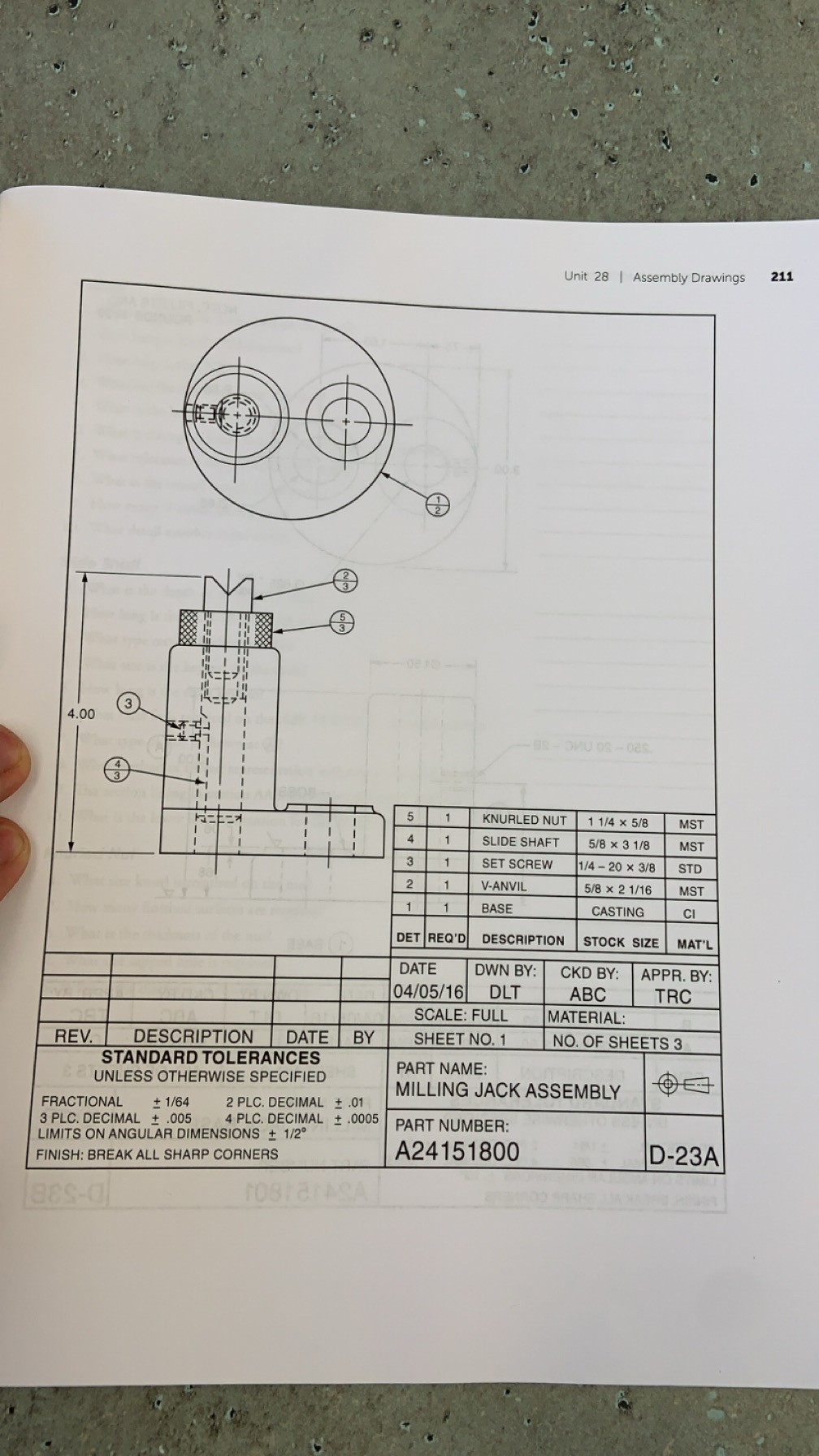

Question: ASSIGNMENT D - 2 3 : MILLING JACK 1 . How many details make up the jack assembly 3 . What is the diameter of

ASSIGNMENT D: MILLING JACK How many details make up the jack assembly What is the diameter of the boss on the jack base? What is the distance from the top of the boss to the top of the base? What is the thickness of the section of the base, not How far is the centerline of the hole from the centerline Whar is the overall height of the assembled jack when it is in Print Reading for including the boss? of the hole? its lowest position? What size is the hole in the slide shaft? What is the detail number of the slide shaft? What is detail How many sheets make up the drawing set? What material is the jack base made of Of what material is the knurled nut made? What is the roughcut stock size of the slide shaft? What is the maximum allowable diameter of the jack base? What is the size of the tapped hole in the jack base? UNLESS OTHERWISE SPECIFIED ANGULAR DWENSIONS EN NL SHARP CORNERS PLC DECIMAL PART NUMBER: Un h Dww IR KNURLED NUT MST MST STO SLIDE SHAFT SET SCREW VANVIL x X ve x X CASTING MST BASE CI DET REQ'D DESCRIPTION STOCK SIZE MATL BEL. DESCRIPTION STANDARD TOLERANCES DATE BY DATE DWN BY: CKD BY: APPR. BY: DLT ABC TRC SCALE: FULL MATERIAL: SHEET NO NO OF SHEETS PART NAME: MILLING JACK ASSEMBLY M PLC DECIMAL DA A What derul number is the anvil? Whats the diameter of the knurled nut? VA How deep is the V What size chamfer is required on the anvil? How long is the diameter? that are the dimensions for the neck? What is the largest diameter for the anvil? What is the upper limit dimension for the diameter Whar tolerance is allowed on the deg angle? What is the overall length of the part? What is the depth of the hole? How long is the UNFA thread? Vanvils are required? How many Whar pe section is shown at AA sat size is the keyseat on the shaft? How long is the shaft keysear? What class fit is required on the UNFa threaded section What type of line is shown ar L What method of thread representation is shown in the front view? The section lining in section AA indicates what type of material: What is the lower limit dimension for the diameter? Shan tuled Nut What size knurl is required on the nut? How many finished surfaces are required? That is the thickness of the nut? Wam size tapped hole is required TY PLC DECIMAL PART NUMBER: MOTE. FILLER R UNC BOSS it BASE ABC WAS A WAS REV DESCRIPTION DATE STANDARD TOLERANCES UNLESS OTHERWISE SPECIFIED PLO DECIMAL DATE DWN BY: CKD BY: HRM DLT HRM SCALE: FULL BY SHEET NO APPRO TRC MATERIAL OI NO OF SHEETS FRACTIONAL BAL DECIMAL UMTS ON ANGULAR DIMENSIONS : PUSH BREAK ALL SHARP CORNERS PART NAME: MILLING JACK BASE AUnit Assembly Drawings

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock