Question: Assignment: Derive Little's Law START ASSIGNMENT Due Sep 15 by 11:59pm Points 15 Submitting a file upload This Assignment Focus (S01 Complex Problem 905 Experiments,

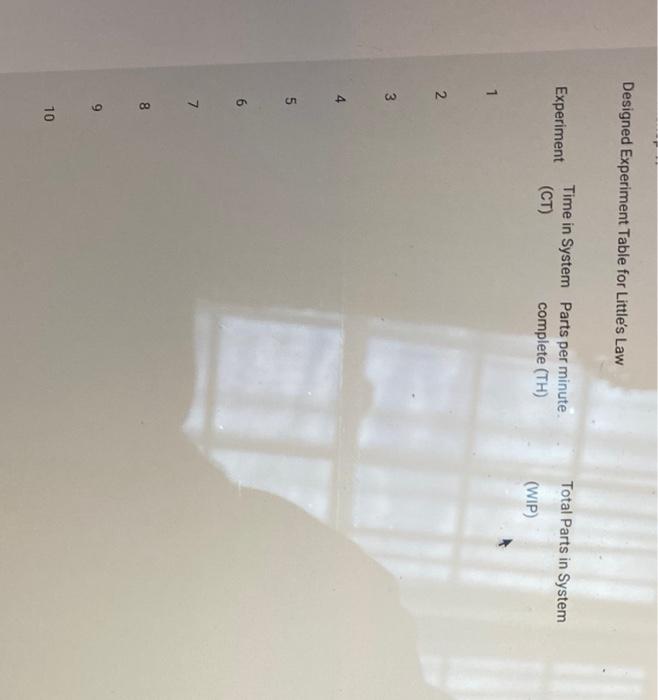

Assignment: Derive Little's Law START ASSIGNMENT Due Sep 15 by 11:59pm Points 15 Submitting a file upload This Assignment Focus (S01 Complex Problem 905 Experiments, S07 Acquire New Independent knowledge) Assignment Instructions Consider the formula for Little's Law where work in process (WIP) is equal to throughput of parts (parts/min) times cycle time (min). In words, the number of parts you have sitting on the production line or in buffers on the line (ie number of chassis on the line for cars) for any manufacturing process will be based on the throughput (number of finished goods or cars per minute) times the time it takes a single chassis to move completely (start to finish) through the entire production process. Little's Law can be applied to a single work-station, multiple workstations, a group workstations working in series/or parallel/or any combination thereof Little's Law is very important to understand how mush work-in-process inventory we will have on average over the long-term basis. That means if you took several sample readings of a production process throughout a given month of production, the number of parts in WIP should converge to Little's Law Also, Little's Law requires that a process be capable of attaining a steady-state'. A steady state means that two things for Little's Law. First, each work station is not unduly starved of work. The means that you don't send one part per day when the system is capable of handling 1,000 parts per day Secondly, it means that the buffers don't build up inventory at any steady or exponential rate. You can't send 1,000 parts per second if the line can only handle 1 part per hour WIP is also considered by the business as a negative thing or dollars on the floor, so businesses like to reduce WIP as much as possible by either increasing TH (parts/min) or decreasing CT (total time in processing) Your assignment here is to research Little's Law and then interpret Little's Law by analyzing the results of your experiment that you ran for your first workshop in your results you have Number in System, Time in System, and Throughput through hour. These correspond to WIP, CT, and TH. In a Word document, please describe Little's Law and then use the data to prove Little's Law. Please complete the following table that is based on your results from Workshop 1. Designed Experiment Table for Little's Law Total Parts in System Experiment Time in Syster Parts per minute (CT) complete (TH) (WIP) Designed Experiment Table for Little's Law Experiment Time in System Parts per minute (CT) complete (TH) Total Parts in System (WIP) 2 3 4 5 6 7 8 9 10 Assignment: Derive Little's Law START ASSIGNMENT Due Sep 15 by 11:59pm Points 15 Submitting a file upload This Assignment Focus (S01 Complex Problem 905 Experiments, S07 Acquire New Independent knowledge) Assignment Instructions Consider the formula for Little's Law where work in process (WIP) is equal to throughput of parts (parts/min) times cycle time (min). In words, the number of parts you have sitting on the production line or in buffers on the line (ie number of chassis on the line for cars) for any manufacturing process will be based on the throughput (number of finished goods or cars per minute) times the time it takes a single chassis to move completely (start to finish) through the entire production process. Little's Law can be applied to a single work-station, multiple workstations, a group workstations working in series/or parallel/or any combination thereof Little's Law is very important to understand how mush work-in-process inventory we will have on average over the long-term basis. That means if you took several sample readings of a production process throughout a given month of production, the number of parts in WIP should converge to Little's Law Also, Little's Law requires that a process be capable of attaining a steady-state'. A steady state means that two things for Little's Law. First, each work station is not unduly starved of work. The means that you don't send one part per day when the system is capable of handling 1,000 parts per day Secondly, it means that the buffers don't build up inventory at any steady or exponential rate. You can't send 1,000 parts per second if the line can only handle 1 part per hour WIP is also considered by the business as a negative thing or dollars on the floor, so businesses like to reduce WIP as much as possible by either increasing TH (parts/min) or decreasing CT (total time in processing) Your assignment here is to research Little's Law and then interpret Little's Law by analyzing the results of your experiment that you ran for your first workshop in your results you have Number in System, Time in System, and Throughput through hour. These correspond to WIP, CT, and TH. In a Word document, please describe Little's Law and then use the data to prove Little's Law. Please complete the following table that is based on your results from Workshop 1. Designed Experiment Table for Little's Law Total Parts in System Experiment Time in Syster Parts per minute (CT) complete (TH) (WIP) Designed Experiment Table for Little's Law Experiment Time in System Parts per minute (CT) complete (TH) Total Parts in System (WIP) 2 3 4 5 6 7 8 9 10