Question: Assignument 2 - Managing Quality This assigrment may be done intividualy or in a group of two students. You will be submating ene completed MSExicel

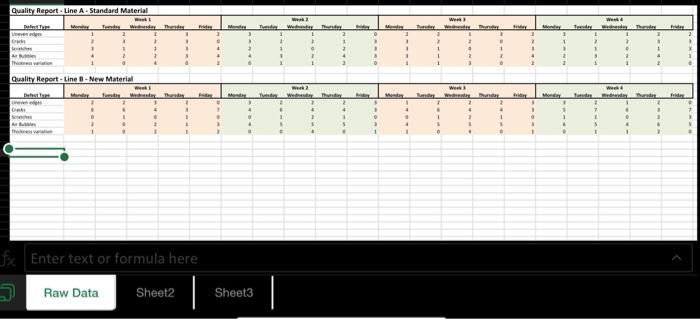

Assignument 2 - Managing Quality This assigrment may be done intividualy or in a group of two students. You will be submating ene completed MSExicel file and a MSWord of POS file in the Assizements tool on Sahai. it you are working with a partser, only one of you should submit the assignmeot, but make sure that hoth names angear prominently on the rubmitted file. Duta for the following evestions are contained in the file oefrap51_F22_Aasignenent2_data. alk. Crse Study-ChckSnop Containers ClickSnap Containers manulacture food grade platic concainers. Ins h\&D Department has recently been working on a aew Bermulation, which will produce plastic that is moch more solerant of changet is tiemperature. Marketing beleves that this new plastic will let Clicksinap obtain much higher market whare in the food container indurtry. At an executive meeting, the Director of asD argued for further testing and fint-hining on the new maserial before in was gut inte production. Marketing argued that in was very important te be first-to-market in ordet to gain a competitive advantage in the market. The tro asked it the preduct was safe and the RsD Director said that there was no doubt absut the materiars safety. Clicisnap has two identical production lines - Line A and Lise s. The CEO made the deciaien to stant preduction using the hew maberial en line B. One month later, the Ogerations Manager was legking at defect reporti from the two lines. This data is shown in the file OPERCPS1_F22_Assienmena2_data als. Wae this data to create the requested quainy eafagement tools and anaeer the following questionk. 1. Use MS Encel colamn chorta to create fwo Parete tharts to analyse the delecth, ohe lor the Standard materal (Line A) and one foe the New material \{line al. in each chart, the columns should be endered trom largest te smallest. The xasis should show the type of defect and the y-axis should shew the sotal number of defests caver the 4 weeki. The y anes should be adjuled so that they show the wame manimum number of delects on both charts. (This makes it easier te viswally cempare the twe charts.) (2 marks) 2. Use MS Excel lise charts to create five Control Chartr, ene for each type of deledt. The x. anis for each chart ahould show the fwenty davi and the -axis should shew Number of Delects. On each control chart, show che fice for the Standard defects and a secend lint for the New defects. The Lower Control Umit for at of the charts as vero. The Upper Centrol timits for each chart are shown is Table A below. is merkif Table A 3. Anwer the following quettions in as MS Word or Por tle. (3 marks ) a. What concluvisns do you reach frem the analpes of these tharts? b. What attions should the Ogerations Manager take? Submit both your MS Encel file with your Partes atd Control Charti and your MS Ward or FDr Hie with your answers to Question 3 . This assignment is due before 11:00 pm on December 1,2022 Quality Repoet - Line A - Standard Material. Quality Repert - tine f - New Material = Enter text or formula here Raw Data Sheet2 Sheet3 Assignument 2 - Managing Quality This assigrment may be done intividualy or in a group of two students. You will be submating ene completed MSExicel file and a MSWord of POS file in the Assizements tool on Sahai. it you are working with a partser, only one of you should submit the assignmeot, but make sure that hoth names angear prominently on the rubmitted file. Duta for the following evestions are contained in the file oefrap51_F22_Aasignenent2_data. alk. Crse Study-ChckSnop Containers ClickSnap Containers manulacture food grade platic concainers. Ins h\&D Department has recently been working on a aew Bermulation, which will produce plastic that is moch more solerant of changet is tiemperature. Marketing beleves that this new plastic will let Clicksinap obtain much higher market whare in the food container indurtry. At an executive meeting, the Director of asD argued for further testing and fint-hining on the new maserial before in was gut inte production. Marketing argued that in was very important te be first-to-market in ordet to gain a competitive advantage in the market. The tro asked it the preduct was safe and the RsD Director said that there was no doubt absut the materiars safety. Clicisnap has two identical production lines - Line A and Lise s. The CEO made the deciaien to stant preduction using the hew maberial en line B. One month later, the Ogerations Manager was legking at defect reporti from the two lines. This data is shown in the file OPERCPS1_F22_Assienmena2_data als. Wae this data to create the requested quainy eafagement tools and anaeer the following questionk. 1. Use MS Encel colamn chorta to create fwo Parete tharts to analyse the delecth, ohe lor the Standard materal (Line A) and one foe the New material \{line al. in each chart, the columns should be endered trom largest te smallest. The xasis should show the type of defect and the y-axis should shew the sotal number of defests caver the 4 weeki. The y anes should be adjuled so that they show the wame manimum number of delects on both charts. (This makes it easier te viswally cempare the twe charts.) (2 marks) 2. Use MS Excel lise charts to create five Control Chartr, ene for each type of deledt. The x. anis for each chart ahould show the fwenty davi and the -axis should shew Number of Delects. On each control chart, show che fice for the Standard defects and a secend lint for the New defects. The Lower Control Umit for at of the charts as vero. The Upper Centrol timits for each chart are shown is Table A below. is merkif Table A 3. Anwer the following quettions in as MS Word or Por tle. (3 marks ) a. What concluvisns do you reach frem the analpes of these tharts? b. What attions should the Ogerations Manager take? Submit both your MS Encel file with your Partes atd Control Charti and your MS Ward or FDr Hie with your answers to Question 3 . This assignment is due before 11:00 pm on December 1,2022 Quality Repoet - Line A - Standard Material. Quality Repert - tine f - New Material = Enter text or formula here Raw Data Sheet2 Sheet3