Question: b. Develop an aggregate plan using the same strategy from part a, except that backlogs are allowed here. There should be no backlog remaining at

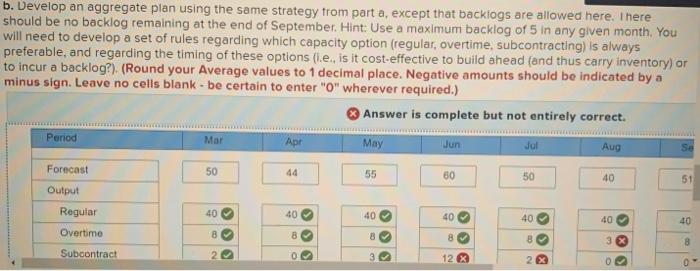

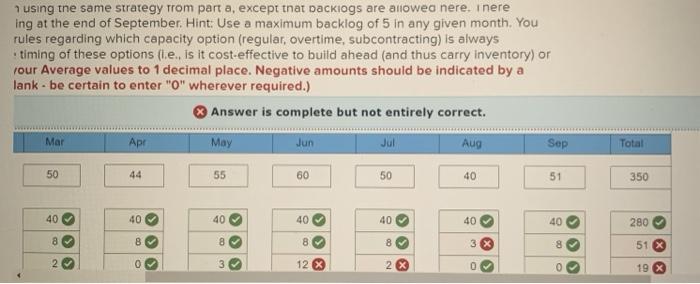

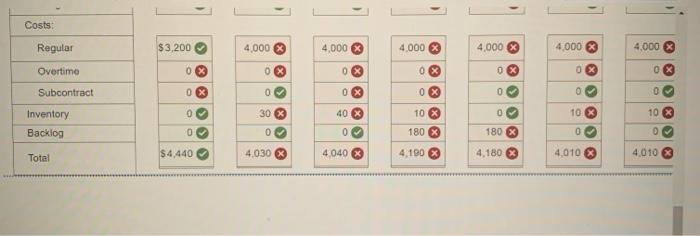

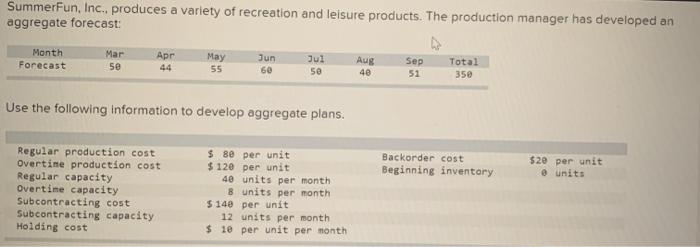

b. Develop an aggregate plan using the same strategy from part a, except that backlogs are allowed here. There should be no backlog remaining at the end of September. Hint: Use a maximum backlog of 5 in any given month. You will need to develop a set of rules regarding which capacity option (regular, overtime, subcontracting) is always preferable, and regarding the timing of these options (l.e., is it cost-effective to build ahead (and thus carry inventory) or to incur a backlog?). (Round your Average values to 1 decimal place. Negative amounts should be indicated by a minus sign. Leave no cells blank.be certain to enter "0" wherever required.) Answer is complete but not entirely correct. Period Mar Apr May Jun Jul Aug 50 Forecast Output 55 60 50 10 51 40 40 40 40 40 > > > 40 Regular Overtime Subcontract 40 8 8 8 > 8 3 8 0 8 2 3 12 2 x 0 . using the same strategy from part a, except that backlogs are allowed nere, inere ing at the end of September. Hint: Use a maximum backlog of 5 in any given month. You rules regarding which capacity option (regular, overtime, subcontracting) is always timing of these options (l.e., Is it cost-effective to build ahead (and thus carry Inventory) or your Average values to 1 decimal place. Negative amounts should be indicated by a lank - be certain to enter "0" wherever required.) Answer is complete but not entirely correct. Mar Apr May Jun Jul Aug Sep Total 50 44 55 60 50 40 51 350 40 40 10 40 40 S 40 40 S 280 8 8 8 8 3 X 51 X 8 0 2 0 3 12 X 2 0 19 Costs Regular $3,200 4.000 4,000 4.000 4,000 X 4.000 4,000 X Overtime 0 % 0 X OX 0 % 0 X 0 X Subcontract 0 0 0 X 0 0 x x oo > >> 0 30 X 10 X 0 > 10 10 % Inventory Backlog 40 % 0 0 > 180 180 0 0 Total $4,440 4.030 X 4.040 4.180 4.180 4,010 4,010 SummerFun, Inc., produces a variety of recreation and leisure products. The production manager has developed an aggregate forecast: Month Forecast Mar 5e Apr May 44 Jun 60 55 Jui 50 Aug 40 Sep 51 Total 350 Use the following information to develop aggregate plans. Backorder cost Beginning inventory $20 per unit @ units Regular production cost Overtime production cost Regular capacity Overtine capacity Subcontracting cost Subcontracting capacity Holding cost $ 8e per unit $ 120 per unit 40 units per month 8 units per month $ 140 per unit 12 units per month $10 per unit per month b. Develop an aggregate plan using the same strategy from part a, except that backlogs are allowed here. There should be no backlog remaining at the end of September. Hint: Use a maximum backlog of 5 in any given month. You will need to develop a set of rules regarding which capacity option (regular, overtime, subcontracting) is always preferable, and regarding the timing of these options (l.e., is it cost-effective to build ahead (and thus carry inventory) or to incur a backlog?). (Round your Average values to 1 decimal place. Negative amounts should be indicated by a minus sign. Leave no cells blank.be certain to enter "0" wherever required.) Answer is complete but not entirely correct. Period Mar Apr May Jun Jul Aug 50 Forecast Output 55 60 50 10 51 40 40 40 40 40 > > > 40 Regular Overtime Subcontract 40 8 8 8 > 8 3 8 0 8 2 3 12 2 x 0 . using the same strategy from part a, except that backlogs are allowed nere, inere ing at the end of September. Hint: Use a maximum backlog of 5 in any given month. You rules regarding which capacity option (regular, overtime, subcontracting) is always timing of these options (l.e., Is it cost-effective to build ahead (and thus carry Inventory) or your Average values to 1 decimal place. Negative amounts should be indicated by a lank - be certain to enter "0" wherever required.) Answer is complete but not entirely correct. Mar Apr May Jun Jul Aug Sep Total 50 44 55 60 50 40 51 350 40 40 10 40 40 S 40 40 S 280 8 8 8 8 3 X 51 X 8 0 2 0 3 12 X 2 0 19 Costs Regular $3,200 4.000 4,000 4.000 4,000 X 4.000 4,000 X Overtime 0 % 0 X OX 0 % 0 X 0 X Subcontract 0 0 0 X 0 0 x x oo > >> 0 30 X 10 X 0 > 10 10 % Inventory Backlog 40 % 0 0 > 180 180 0 0 Total $4,440 4.030 X 4.040 4.180 4.180 4,010 4,010 SummerFun, Inc., produces a variety of recreation and leisure products. The production manager has developed an aggregate forecast: Month Forecast Mar 5e Apr May 44 Jun 60 55 Jui 50 Aug 40 Sep 51 Total 350 Use the following information to develop aggregate plans. Backorder cost Beginning inventory $20 per unit @ units Regular production cost Overtime production cost Regular capacity Overtine capacity Subcontracting cost Subcontracting capacity Holding cost $ 8e per unit $ 120 per unit 40 units per month 8 units per month $ 140 per unit 12 units per month $10 per unit per month