Question: b) How many orders do we have to place for Component C and in what quantities? c) Suppose the lead time for Component G is

b) How many orders do we have to place for Component C and in what quantities?

c) Suppose the lead time for Component G is two weeks instead of one week, what will its impact be on the planning process?

d) Suppose that the economic order quantity for Component C is 320 units. What will the appropriate POQ lot-sizing rule be for Component C?

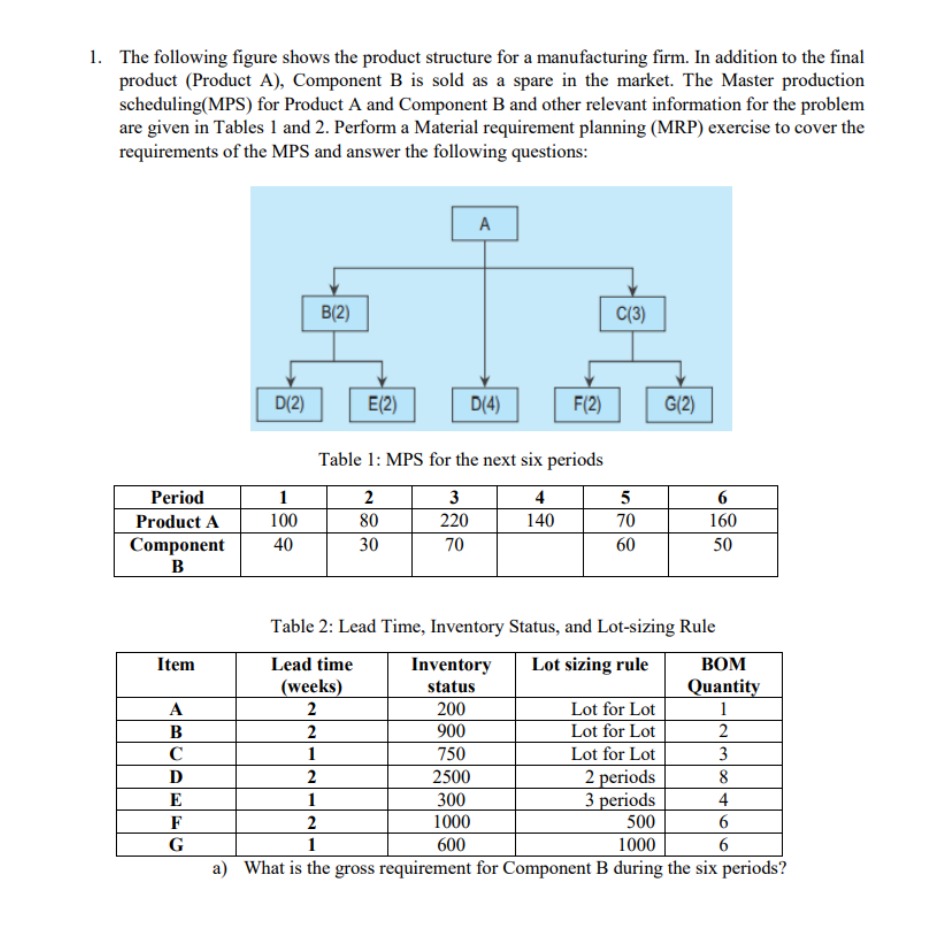

The following figure shows the product structure for a manufacturing firm. In addition to the final product (Product A), Component B is sold as a spare in the market. The Master production scheduling(MPS) for Product A and Component B and other relevant information for the problem are given in Tables 1 and 2. Perform a Material requirement planning (MRP) exercise to cover the requirements of the MPS and answer the following questions: Table 1: MPS for the next six periods Table 2: Lead Time, Inventory Status, and Lot-sizing Rule a) What is the gross requirement for Component B during the six periods

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts