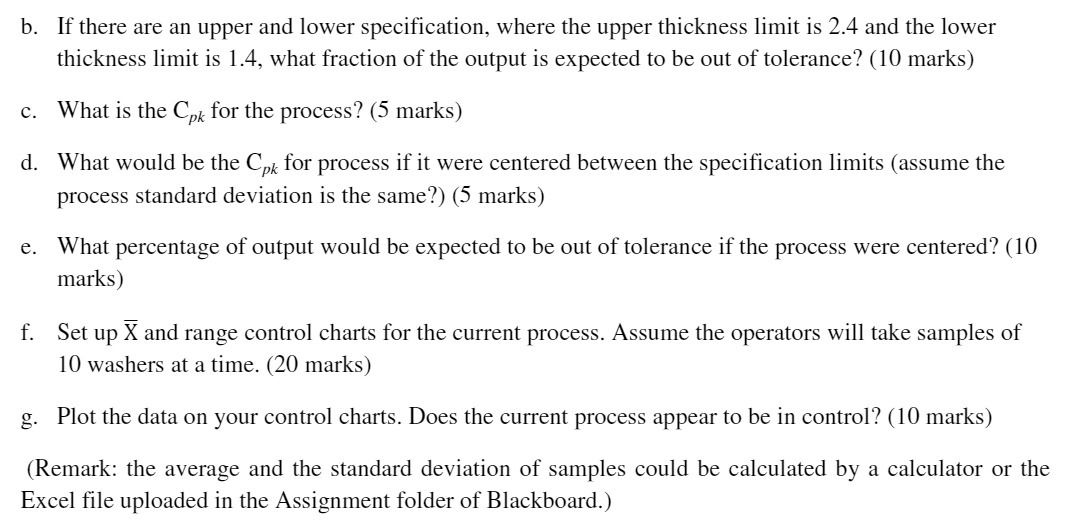

Question: b. If there are an upper and lower specification, where the upper thickness limit is 2.4 and the lower thickness limit is 1.4. what fraction

b. If there are an upper and lower specification, where the upper thickness limit is 2.4 and the lower thickness limit is 1.4. what fraction of the output is expected to be out of tolerance? (10 marks) c. What is the Cpk for the process? (5 marks) d. What would be the Cpk for process if it were centered between the specication limits (assume the process standard deviation is the same?) (5 marks) e. What percentage of output would be expected to be out of tolerance if the process were centered? (10 marks) f. Set up i and range control charts for the current process. Assume the operators will take samples of 10 washers at a time. (20 marks) g. Plot the data on your control charts. Does the current process appear to be in control? (10 marks) (Remark: the average and the standard deviation of samples could be calculated by a calculator or the Excel le uploaded in the Assignment folder of Blackboard.)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts