Question: b. Using the bottleneck-based method, what is the optimal product mix and what is the overall profitability? Please A and B A.J.'s Wildlife Emporium manufactures

b. Using the bottleneck-based method, what is the optimal product mix and what is the overall profitability?

Please A and B

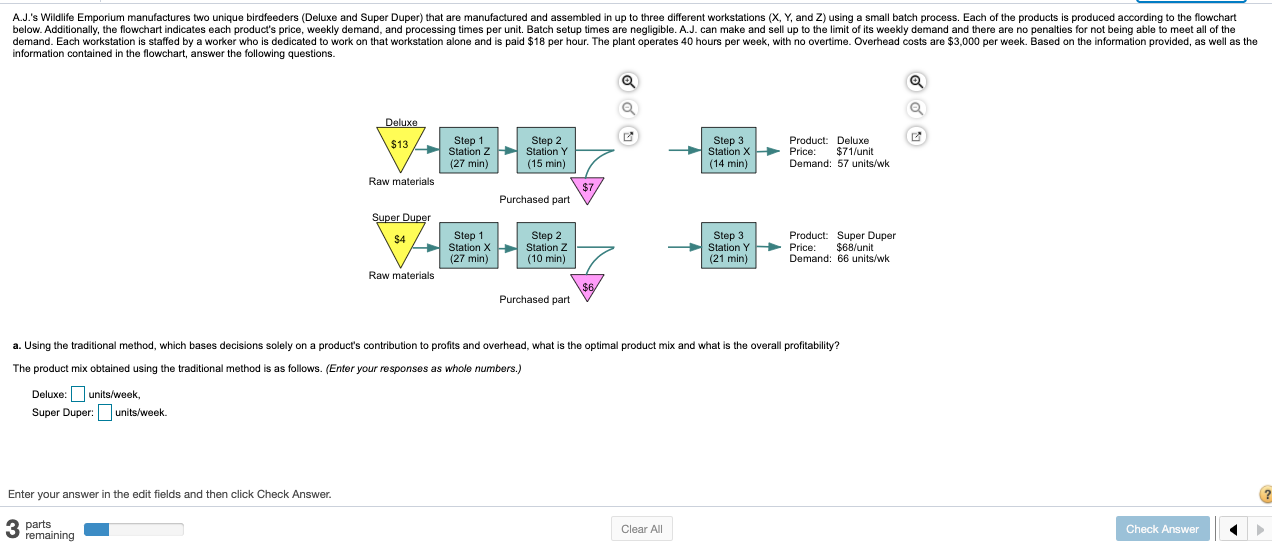

A.J.'s Wildlife Emporium manufactures two unique birdfeeders (Deluxe and Super Duper) that are manufactured and assembled in up to three different workstations (X, Y, and Z) using a small batch process. Each of the products is produced according to the flowchart below. Additionally, the flowchart indicates each product's price, weekly demand, and processing times per unit. Batch setup times are negligible. A.J. can make and sell up to the limit of its weekly demand and there are no penalties for not being able to meet all of the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $18 per hour. The plant operates 40 hours per week, with no overtime. Overhead costs are $3,000 per week. Based on the information provided, as well as the information contained in the flowchart, answer the following questions. Q Q Deluxe $13 Step 1 Station 2 (27 min) Step 2 Station Y (15 min) Step 3 Product: Deluxe Station X - Price: : $71/unit (14 min) Demand: 57 units/wk Raw materials $7 Purchased part Super Duper $4 Step 1 Station X (27 min) Step 2 Station 2 (10 min) Step 3 Station Y (21 min) Product: Super Duper Price: $68/unit Demand: 66 units/wk Raw materials $6 Purchased part a. Using the traditional method, which bases decisions solely on a product's contribution to profits and overhead, what is the optimal product mix and what is the overall profitability? The product mix obtained using the traditional method is as follows. (Enter your responses as whole numbers.) Deluxe: units/week, Super Duper: units/week. Enter your answer in the edit fields and then click Check Answer. ? 3 parts Clear All Check Answer remaining A.J.'s Wildlife Emporium manufactures two unique birdfeeders (Deluxe and Super Duper) that are manufactured and assembled in up to three different workstations (X, Y, and Z) using a small batch process. Each of the products is produced according to the flowchart below. Additionally, the flowchart indicates each product's price, weekly demand, and processing times per unit. Batch setup times are negligible. A.J. can make and sell up to the limit of its weekly demand and there are no penalties for not being able to meet all of the demand. Each workstation is staffed by a worker who is dedicated to work on that workstation alone and is paid $18 per hour. The plant operates 40 hours per week, with no overtime. Overhead costs are $3,000 per week. Based on the information provided, as well as the information contained in the flowchart, answer the following questions. Q Q Deluxe $13 Step 1 Station 2 (27 min) Step 2 Station Y (15 min) Step 3 Product: Deluxe Station X - Price: : $71/unit (14 min) Demand: 57 units/wk Raw materials $7 Purchased part Super Duper $4 Step 1 Station X (27 min) Step 2 Station 2 (10 min) Step 3 Station Y (21 min) Product: Super Duper Price: $68/unit Demand: 66 units/wk Raw materials $6 Purchased part a. Using the traditional method, which bases decisions solely on a product's contribution to profits and overhead, what is the optimal product mix and what is the overall profitability? The product mix obtained using the traditional method is as follows. (Enter your responses as whole numbers.) Deluxe: units/week, Super Duper: units/week. Enter your answer in the edit fields and then click Check Answer. ? 3 parts Clear All Check Answer remainingStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts