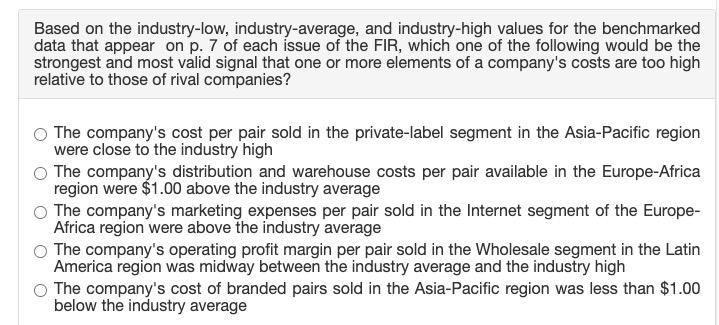

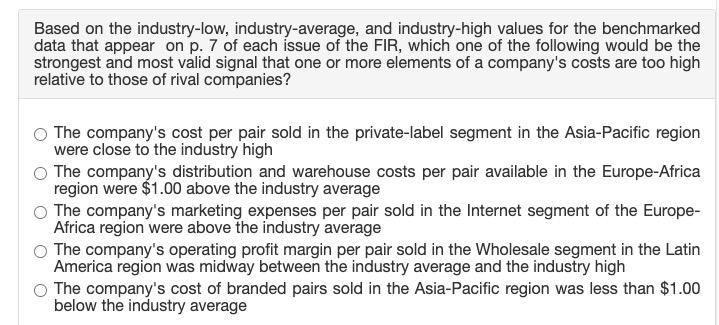

Question: Based on the industry-low, industry-average, and industry-high values for the benchmarked data that appear on p. 7 of each issue of the FIR, which one

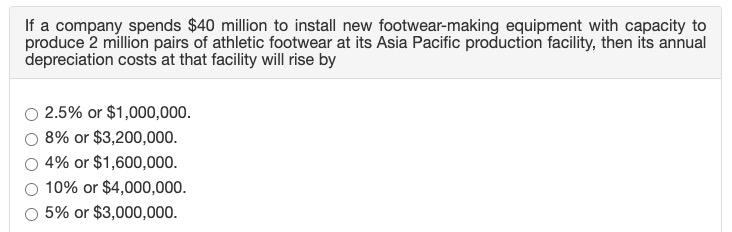

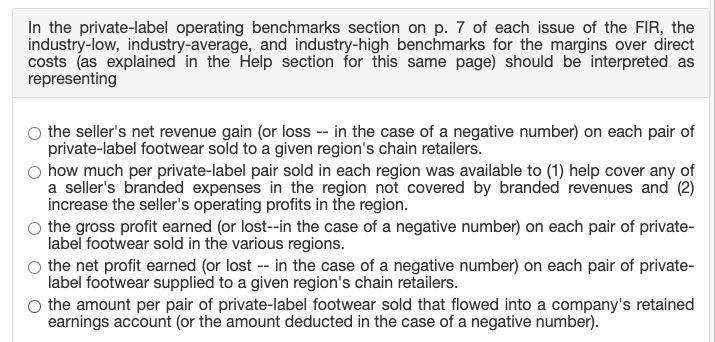

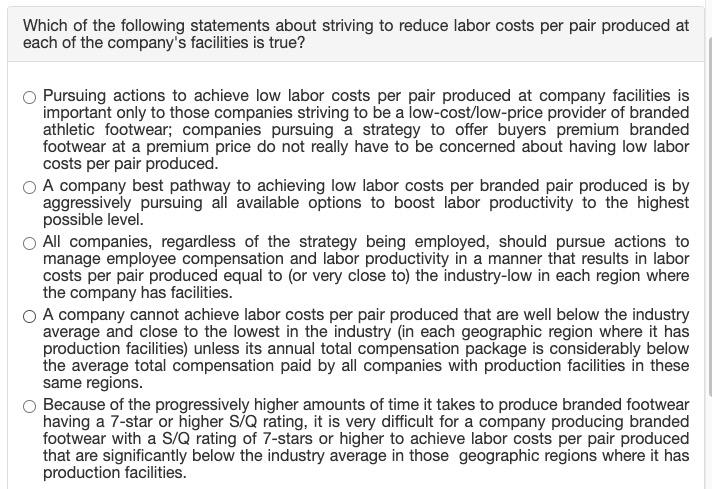

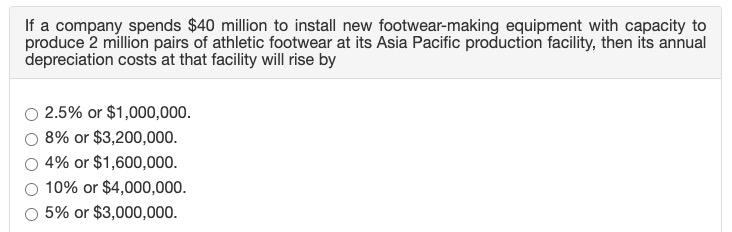

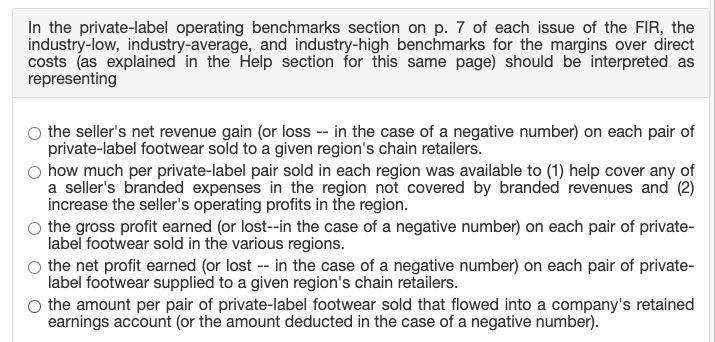

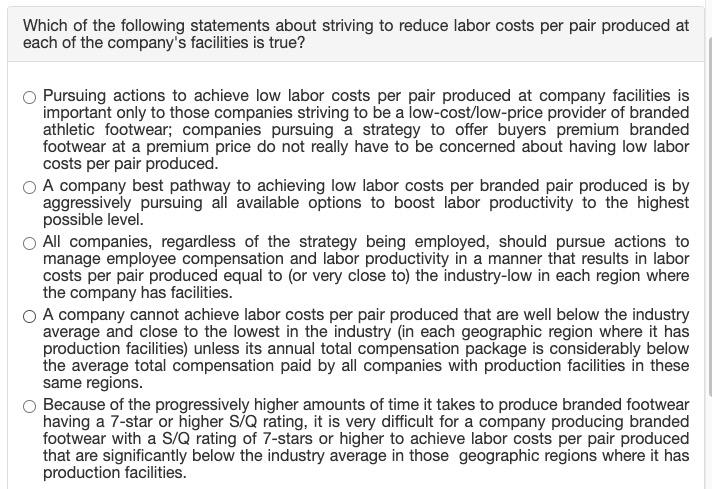

Based on the industry-low, industry-average, and industry-high values for the benchmarked data that appear on p. 7 of each issue of the FIR, which one of the following would be the strongest and most valid signal that one or more elements of a company's costs are too high relative to those of rival companies? The company's cost per pair sold in the private-label segment in the Asia-Pacific region were close to the industry high The company's distribution and warehouse costs per pair available in the Europe-Africa region were $1.00 above the industry average The company's marketing expenses per pair sold in the Internet segment of the Europe- Africa region were above the industry average The company's operating profit margin per pair sold in the Wholesale segment in the Latin America region was midway between the industry average and the industry high The company's cost of branded pairs sold in the Asia-Pacific region was less than $1.00 below the industry average If a company spends $40 million to install new footwear-making equipment with capacity to produce 2 million pairs of athletic footwear at its Asia Pacific production facility, then its annual depreciation costs at that facility will rise by 2.5% or $1,000,000 8% or $3,200,000 4% or $1,600,000. 10% or $4,000,000 5% or $3,000,000. In the private-label operating benchmarks section on p. 7 of each issue of the FIR, the industry-low, industry-average, and industry-high benchmarks for the margins over direct costs (as explained in the Help section for this same page) should be interpreted as representing the seller's net revenue gain (or loss -- in the case of a negative number) on each pair of private-label footwear sold to a given region's chain retailers. how much per private-label pair sold in each region was available to (1) help cover any of a seller's branded expenses in the region not covered by branded revenues and (2) increase the seller's operating profits in the region. the gross profit earned (or lost--in the case of a negative number) on each pair of private- label footwear sold in the various regions. the net profit earned (or lost -- in the case of a negative number) on each pair of private- label footwear supplied to a given region's chain retailers. the amount per pair of private-label footwear sold that flowed into a company's retained earnings account (or the amount deducted in the case of a negative number). Which of the following statements about striving to reduce labor costs per pair produced at each of the company's facilities is true? Pursuing actions to achieve low labor costs per pair produced at company facilities is important only to those companies striving to be a low-cost/low-price provider of branded athletic footwear; companies pursuing a strategy to offer buyers premium branded footwear at a premium price do not really have to be concerned about having low labor costs per pair produced. A company best pathway to achieving low labor costs per branded pair produced is by aggressively pursuing all available options to boost labor productivity to the highest possible level. All companies, regardless of the strategy being employed, should pursue actions to manage employee compensation and labor productivity in a manner that results in labor costs per pair produced equal to (or very close to) the industry-low in each region where the company has facilities. O A company cannot achieve labor costs per pair produced that are well below the industry average and close to the lowest in the industry (in each geographic region where it has production facilities) unless its annual total compensation package is considerably below the average total compensation paid by all companies with production facilities in these same regions. Because of the progressively higher amounts of time it takes to produce branded footwear having a 7-star or higher S/Q rating, it is very difficult for a company producing branded footwear with a S/Q rating of 7-stars or higher to achieve labor costs per pair produced that are significantly below the industry average in those geographic regions where it has production facilities