Question: Based on the text provided need help answering these two accounting questions. The speed of the canning line is a common chokepoint in craft breweries,

Based on the text provided need help answering these two accounting questions.

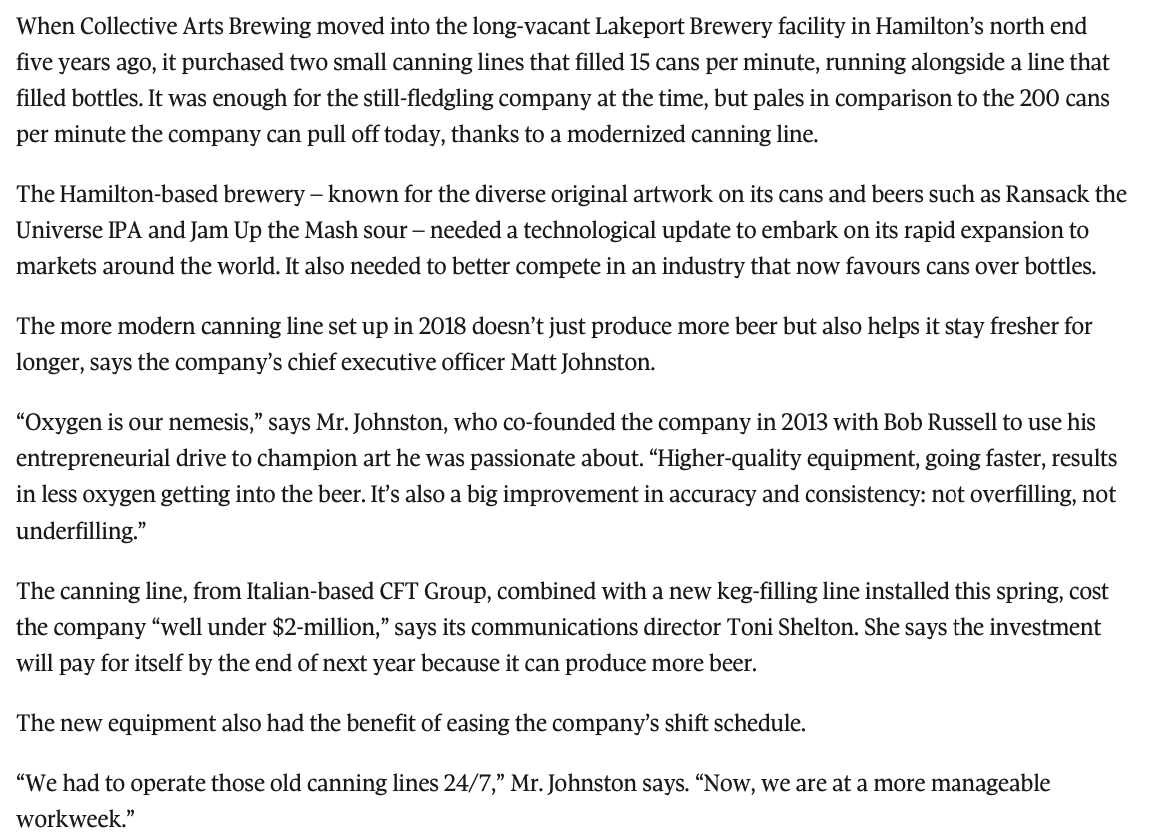

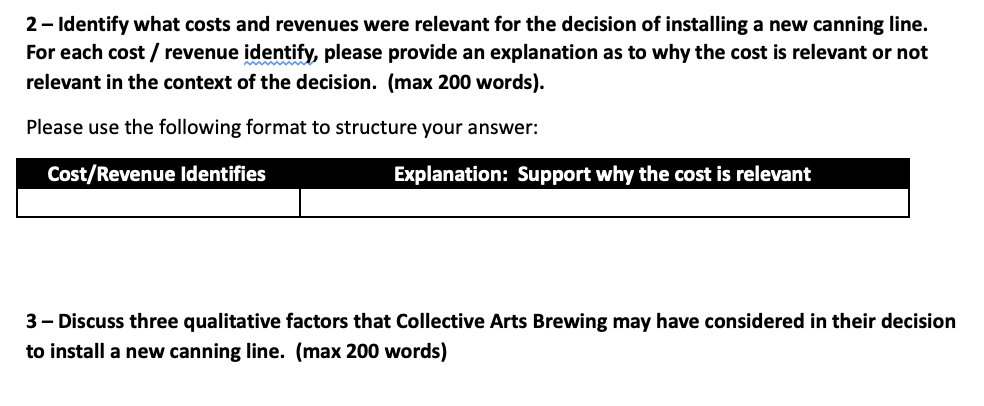

The speed of the canning line is a common chokepoint in craft breweries, according to Niagara College professor Jon Downing, a professor in the school's brewmaster program. The line typically sanitizes the cans, dries them, fills them with beer and attaches the lid. Better lines move more quickly and fill more cans per minute, sometimes simultaneously, says Downing, who opened Ontario's first brewpub, The Atlas Hotel, in Welland in 1986. The fancy ones evacuate the air from the cans and pressurize them with carbon dioxide so the can is filled faster, Mr. Downing adds. Very tiny amounts of oxygen will spoil beer - 60 or 70 parts per billion, he explains, adding that a 200-can- per-minute line, such as the one at Collective Arts, is likely faster than lines at most craft breweries in Canada. Many breweries fill between 40 cans and 80 cans per minute. On the other end of the spectrum are giants such Molson and Labatt, whose lines run somewhere near 500 cans a minute, Mr. Downing says. For a small brewery trying to expand, the technology is the difference, he says. Contrary to expectations, a more automated canning line doesn't typically reduce the number of employees needed in the brewery, Mr. Downing adds. To make the most of the new asset, brewers will move workers into areas such as quality control and lab work and increase brewing capacity so that the canning line doesn't sit idle. Collective Arts, which has about 150 employees, has kept its canning staff in packaging roles and eliminated the need for night shifts. In addition to speed and quality improvements, a new canning line can also help breweries reduce their losses, says brewing consultant Kyle Smith, owner of Gorman & Smith Beverage Equipment. Mr. Smith says older lines tend to be less precise, meaning the cans end up underfilled and unsuitable for sale. "You have so much hat you're starting with, and you want to get as much in the packaged product as possible, Mr. Smith says. To correct or prevent short fills, brewers tend to overfill the package to help reduce the chance of ... being out of spec. Better to be over than under. He says a more consistent packaging line can "easily save 3 per cent to 4 per cent more beer that would otherwise have been used for overfilling. That's ... a big increase to your total product volume, Mr. Smith says. With the new canning line in place, Collective Arts has removed its bottling line completely. The industry has shifted over to cans, and for us, it's a better representation of the artists, Mr. Johnston says. Collective Arts does use bottles for its gin, but that is bottled off-site, says Ms. Shelton. Collective Arts plans to open a small brewpub in Toronto this month and is working on opening a brewery in New York City, where it sees strong sales of its products today. We're still working to expand globally, quickly, Mr. Johnston says, adding the brand is now in nearly 20 countries, focused on markets with vibrant arts communities such as Seoul, London and Stockholm. We want to be seen as the beer of creativity. The company's creative branding, investment in technology and, of course, its beer, has helped its sales grow by an average annual compound growth rate of 60 per cent since 2015 demand that has been met by the addition of the new canning line. At this point, it's sustainable, he says of the company's growth. 2- Identify what costs and revenues were relevant for the decision of installing a new canning line. For each cost / revenue identify, please provide an explanation as to why the cost is relevant or not relevant in the context of the decision. (max 200 words). Please use the following format to structure your answer: Cost/Revenue Identifies Explanation: Support why the cost is relevant 3 - Discuss three qualitative factors that Collective Arts Brewing may have considered in their decision to install a new canning line. (max 200 words) The speed of the canning line is a common chokepoint in craft breweries, according to Niagara College professor Jon Downing, a professor in the school's brewmaster program. The line typically sanitizes the cans, dries them, fills them with beer and attaches the lid. Better lines move more quickly and fill more cans per minute, sometimes simultaneously, says Downing, who opened Ontario's first brewpub, The Atlas Hotel, in Welland in 1986. The fancy ones evacuate the air from the cans and pressurize them with carbon dioxide so the can is filled faster, Mr. Downing adds. Very tiny amounts of oxygen will spoil beer - 60 or 70 parts per billion, he explains, adding that a 200-can- per-minute line, such as the one at Collective Arts, is likely faster than lines at most craft breweries in Canada. Many breweries fill between 40 cans and 80 cans per minute. On the other end of the spectrum are giants such Molson and Labatt, whose lines run somewhere near 500 cans a minute, Mr. Downing says. For a small brewery trying to expand, the technology is the difference, he says. Contrary to expectations, a more automated canning line doesn't typically reduce the number of employees needed in the brewery, Mr. Downing adds. To make the most of the new asset, brewers will move workers into areas such as quality control and lab work and increase brewing capacity so that the canning line doesn't sit idle. Collective Arts, which has about 150 employees, has kept its canning staff in packaging roles and eliminated the need for night shifts. In addition to speed and quality improvements, a new canning line can also help breweries reduce their losses, says brewing consultant Kyle Smith, owner of Gorman & Smith Beverage Equipment. Mr. Smith says older lines tend to be less precise, meaning the cans end up underfilled and unsuitable for sale. "You have so much hat you're starting with, and you want to get as much in the packaged product as possible, Mr. Smith says. To correct or prevent short fills, brewers tend to overfill the package to help reduce the chance of ... being out of spec. Better to be over than under. He says a more consistent packaging line can "easily save 3 per cent to 4 per cent more beer that would otherwise have been used for overfilling. That's ... a big increase to your total product volume, Mr. Smith says. With the new canning line in place, Collective Arts has removed its bottling line completely. The industry has shifted over to cans, and for us, it's a better representation of the artists, Mr. Johnston says. Collective Arts does use bottles for its gin, but that is bottled off-site, says Ms. Shelton. Collective Arts plans to open a small brewpub in Toronto this month and is working on opening a brewery in New York City, where it sees strong sales of its products today. We're still working to expand globally, quickly, Mr. Johnston says, adding the brand is now in nearly 20 countries, focused on markets with vibrant arts communities such as Seoul, London and Stockholm. We want to be seen as the beer of creativity. The company's creative branding, investment in technology and, of course, its beer, has helped its sales grow by an average annual compound growth rate of 60 per cent since 2015 demand that has been met by the addition of the new canning line. At this point, it's sustainable, he says of the company's growth. 2- Identify what costs and revenues were relevant for the decision of installing a new canning line. For each cost / revenue identify, please provide an explanation as to why the cost is relevant or not relevant in the context of the decision. (max 200 words). Please use the following format to structure your answer: Cost/Revenue Identifies Explanation: Support why the cost is relevant 3 - Discuss three qualitative factors that Collective Arts Brewing may have considered in their decision to install a new canning line. (max 200 words)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts