Question: BTF Engineering has received a one-time contract to design and build 20,000 units of a new product. During the proposal process, management felt that the

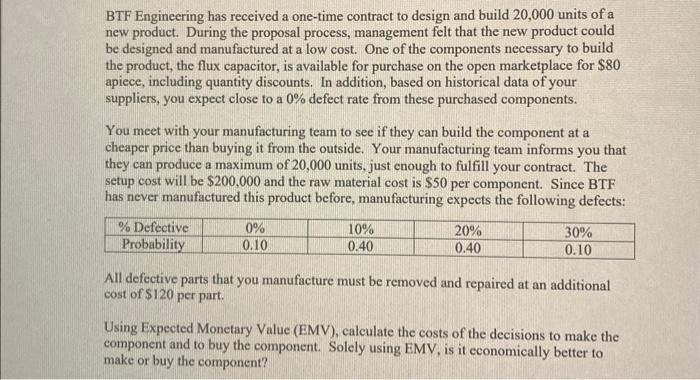

BTF Engineering has received a one-time contract to design and build 20,000 units of a new product. During the proposal process, management felt that the new product could be designed and manufactured at a low cost. One of the components necessary to build the product, the flux capacitor, is available for purchase on the open marketplace for $80 apiece, including quantity discounts. In addition, based on historical data of your suppliers, you expect close to a 0% defect rate from these purchased components. You meet with your manufacturing team to see if they can build the component at a cheaper price than buying it from the outside. Your manufacturing team informs you that they can produce a maximum of 20,000 units, just cnough to fulfill your contract. The setup cost will be $200,000 and the raw material cost is $50 per component. Since BTF has never manufactured this product before, manufacturing expects the following defects: All defective parts that you manufacture must be removed and repaired at an additional cost of $120 per part. Using Expected Monetary Value (EMV), calculate the costs of the decisions to make the component and to buy the component. Solely using EMV, is it economically better to make or buy the component

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts