Question: . business is trying to achieve and what they are expected to do in their jobs. She knows that departmental managers should set and contribute

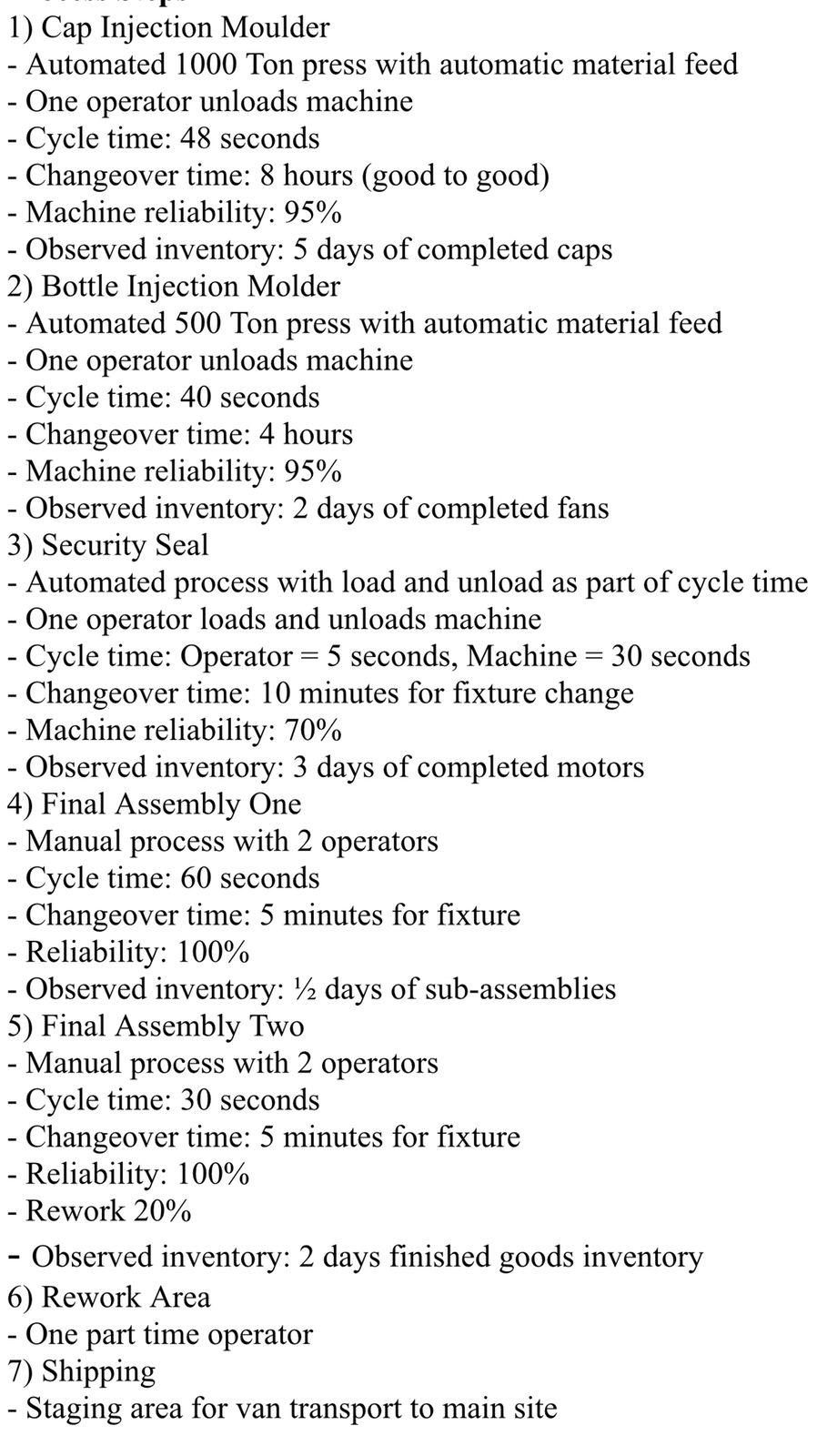

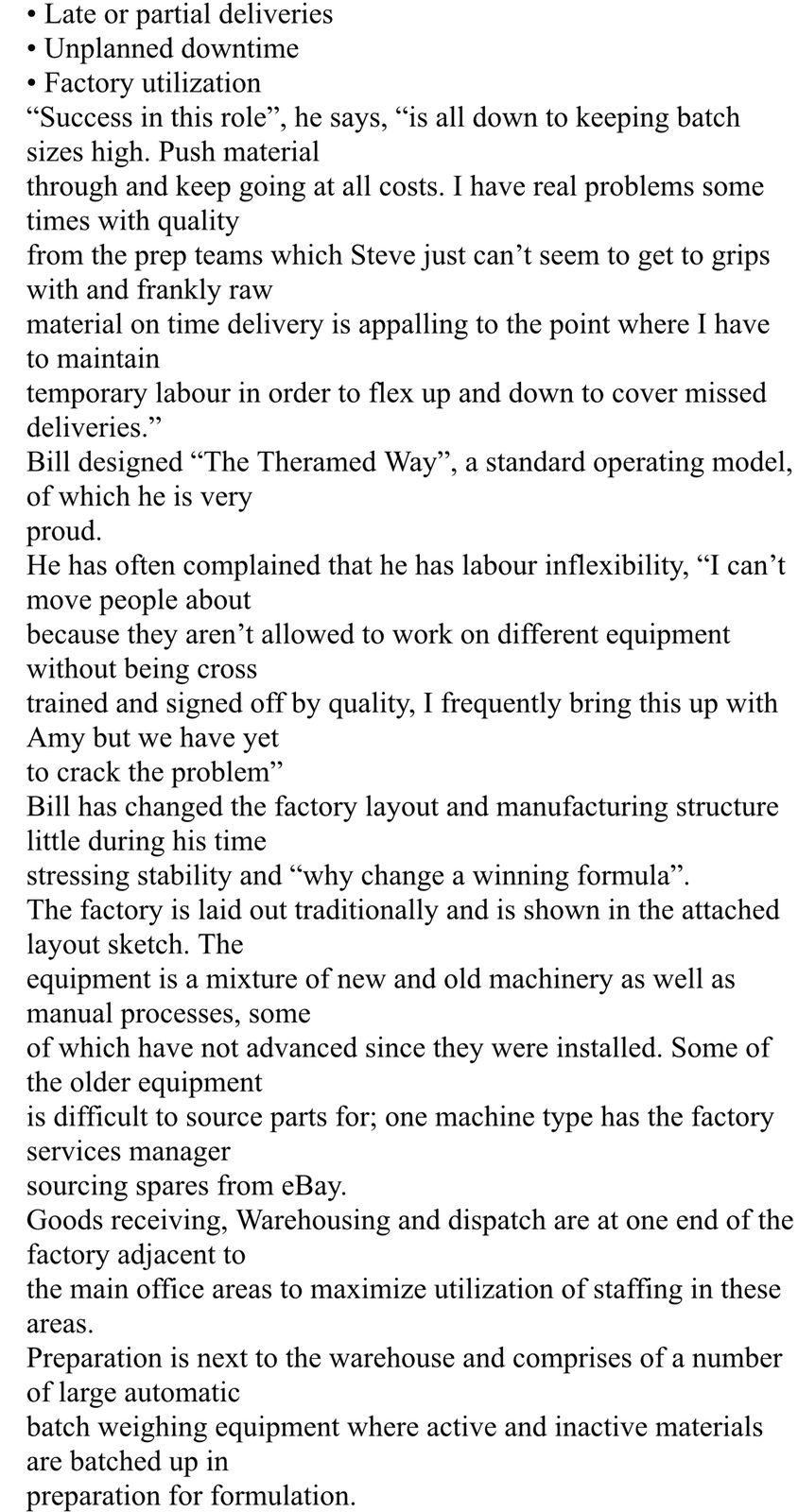

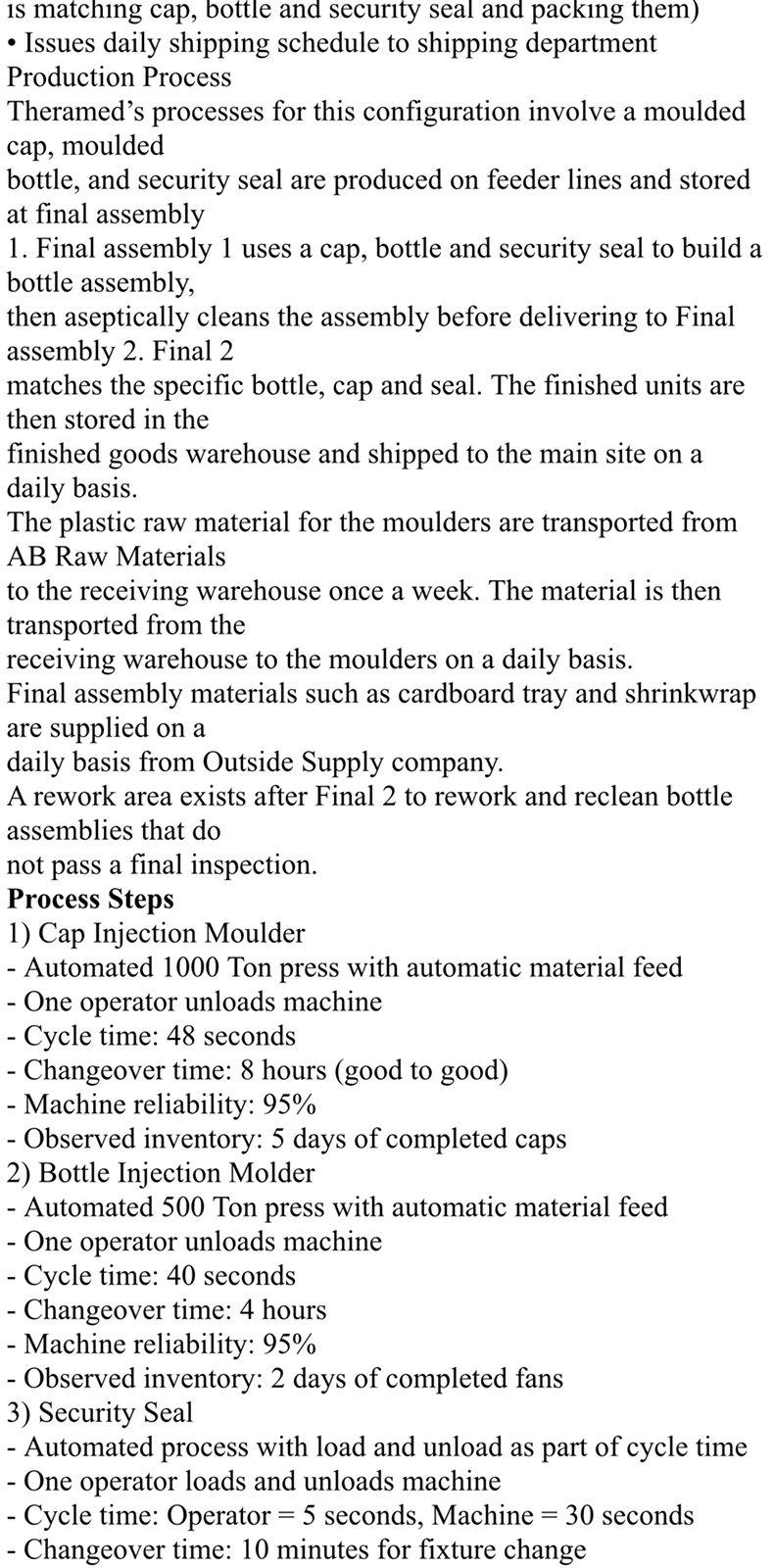

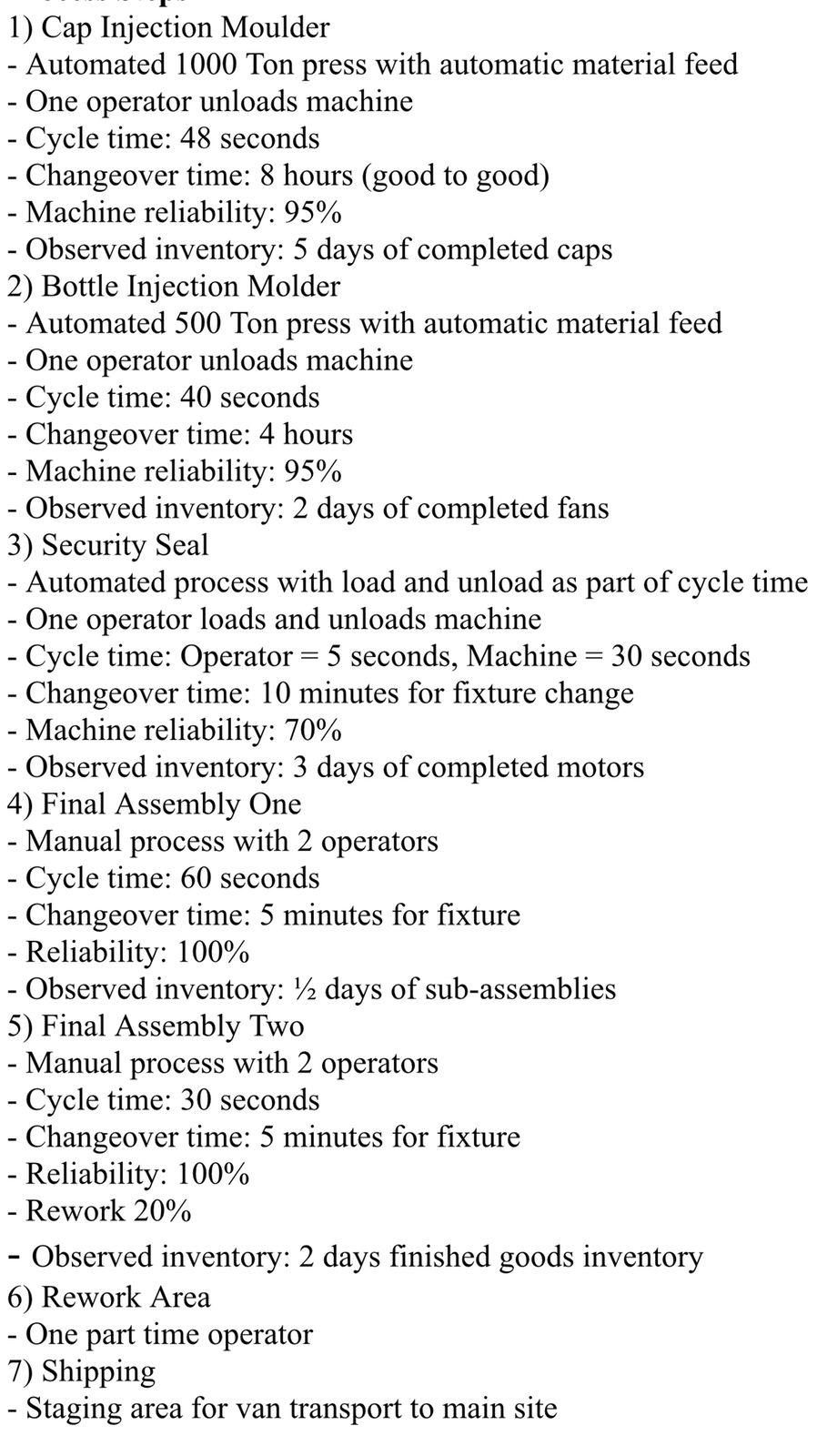

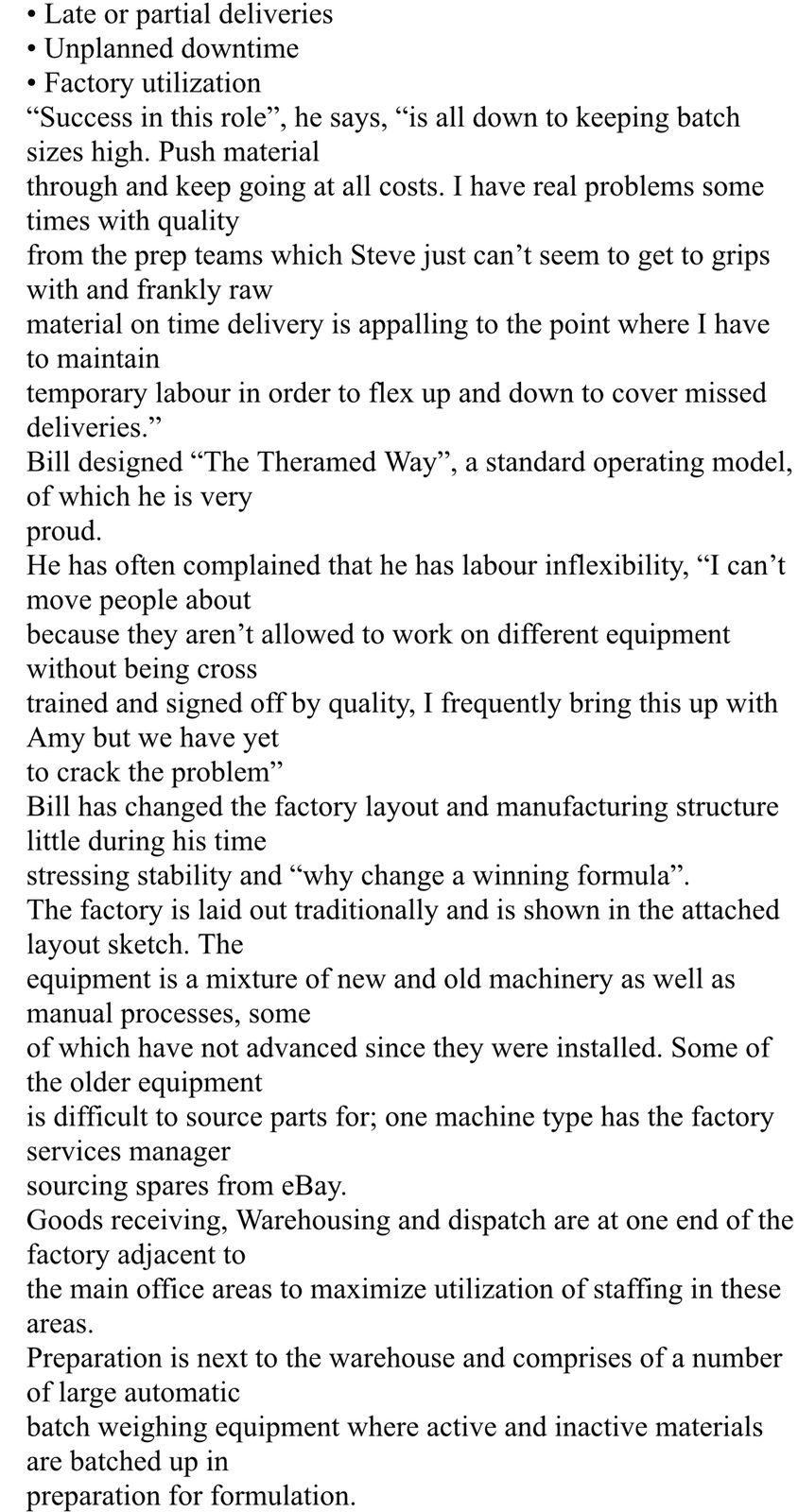

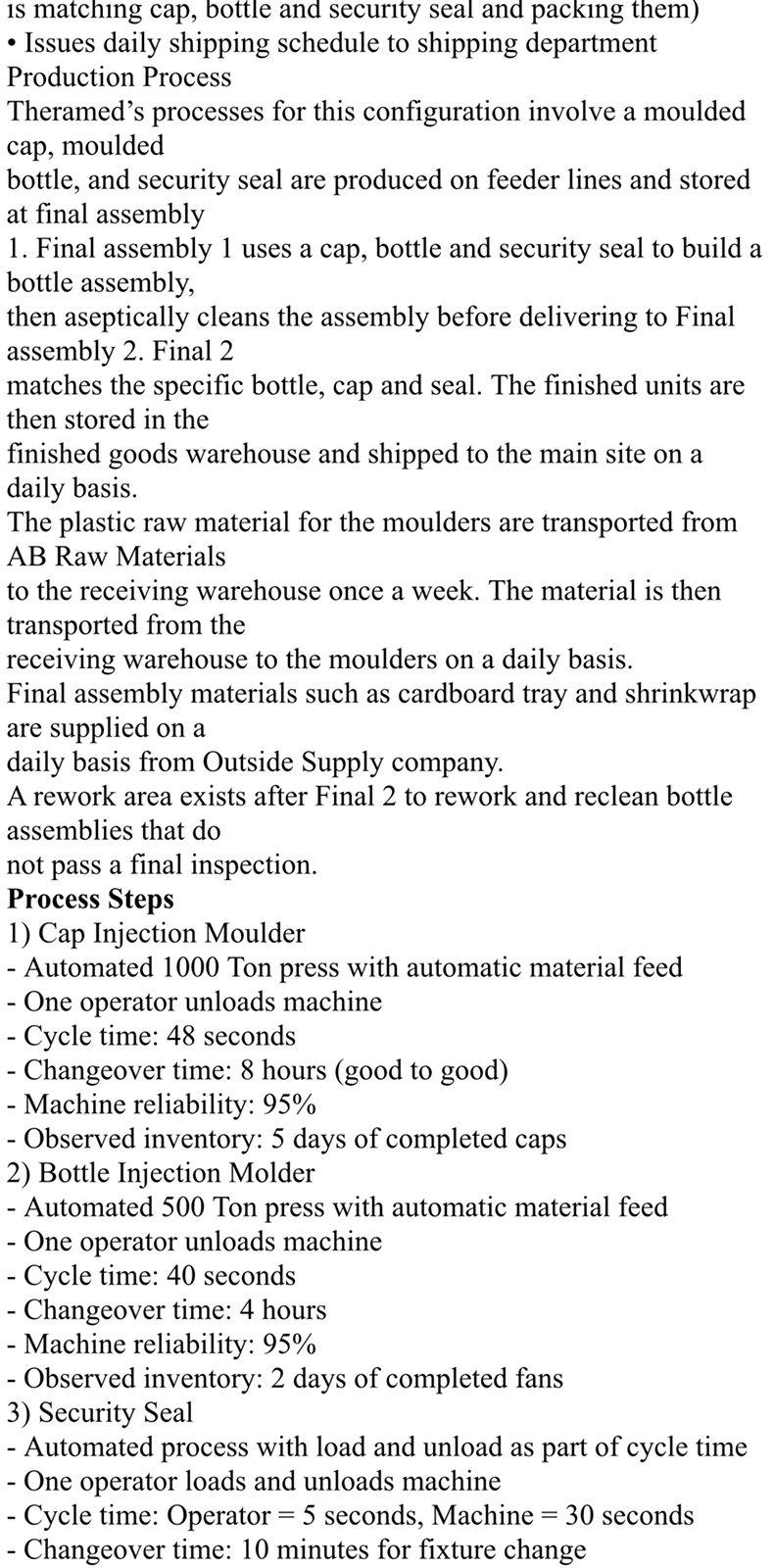

. business is trying to achieve and what they are expected to do in their jobs. She knows that departmental managers should set and contribute targets more but doesn't know how to engage her colleagues in the task. Internal communications are largely unplanned and the underground rumour machine thrives. She makes sure that the business follows all the legal requirements and also has responsibility for Health & Safety regulations. Amy also looks after training, "we take people on with the aim that they can do the job, they are made aware if their performance is not satisfactory. Pete Gabriel (Materials Supply) As well as managing purchased materials Pete also has responsibility for the warehouse and distribution. The measures for which he is responsible are; Supplier performance (on time) Value of finished goods stock Value of raw material stock Raw materials price Most of our relationships with suppliers are driven based on price, or because we find it difficult to resource supply he says. I try hard to make sure production isn't affected by late suppliers and work to keep costs down, sometimes quality could be improved but it doesn't seem to cause too many problems. Other members of staff have doubts over whether Pete really has influence over the areas he controls or whether manufacturing operations has effectively "annexed this part of the business. A specific issue has been identified in the distribution centre, many customers report dissatisfaction with the way the distribution centre operates. The distribution centre operates a "round the clock service which is supported by an outsourced contact centre. Four teams receive inbound product orders for one or more of the 3 main product volumes from various global regions. just didn't seem see it as a problem. In another incident filled product, recovered from dose checks and improperly sealed bottles, was dumped into a holding tank, and once in the tank, was pumped back to the main product holding tank. It was mixed with the product in the holding tank, refiltered and filled again during the course of the filling operations. No one knew it was happening until it was done, it was a fait accompli. I don't think FDA or any other regulato agency would find this to be an acceptable practice. Steve's department is responsible for generating Standard Operating Procedures but, I don't see the point. Operations don't use them unless there is an audit coming and some of the temporary staff aren't around long enough to even read some of them. We always catch the problems but never get the root cause solved. Steve has a development of one of their existing drugs ready, an encapsulated form of one of their liquid products that should help them retain business but has not sought patient or prescriber feedback. Manufacturing Operations are reluctant to staff a pilot plant as they see this as additional workload for no return. Amy Wadge (Human Resources) Amy was promoted from HR officer, a post she had held for over 8 years, 2 years 2 ago. Amy finds herself managing wage issues, disputes, absences and "welfare issues. As a result of this she insists that all salary and wage increases are sanctioned by her, a number of the managers have promised their reports increases which Amy has vetoed causing friction between her and other managers. People receive their salaries and wages in recognition of their contribution, she . . Bottle Manufacture A small industrial unit is located about 5 miles away from Theramed which manufactures the product bottles in an aseptic facility. The management team believe that there may be issues in the bottle production which are constraining the ability of the business to respond to customer demand. Bottle are produced in many configurations, once produced they are sent to the main Theramed production site (the bottle site's customer). Because Theramed makes a wide variety of bottle configurations a and customer requirements vary significantly across regions and within regions, current lead time for supply to the active ingredient site is more than 10 days. The management team believe that to resolve some of the customer issues they must be able to reduce the lead time to 1 day. Bottle Process Data Follows: Main Site (customer) Requirements 20,000 units per month Average order size is 500 20 pieces per shipping module (a tray of bottles) Two daily shipments (one per shift) Units are ordered and expected next day Work Time 20 days per month Two shift operation in all departments Eight hours per shift, with overtime if needed Two 15 - minute breaks Unpaid lunch Production Control Information Receives main site 10 day, 10 week, 10 month forecasts and enters them into MRP. Receives daily order from main site Order released via MRP once a week to Raw Materials and Outside Supply Company Generates MRP-based weekly production requirements based on customer orders, inventory levels, downtime, and scrap Issues weekly build schedule to cap, bottle, security seal, and final assembly 1 and 2 processes (final assy 1 is an aseptic cleaning process and final assembly 2 is matching cap, bottle and security sealand packing them) . . . . . The Formulation department consists of a number of automatic mixing equipment complete with temperature, speed and ingredient addition monitoring systems. In common with the Preparation department the general practice is to run as large batch sizes as possible to maximize utilization and keep busy. Running large batches also allows time for the equipment to be cleaned between batches. As they have aged they have also become increasingly unreliable and long breakdowns are not uncommon. The Formulation managers work hard to keep the Fill & Finish team busy. Fill & Finish comprises of 2 automated and 1 semi automated filling lines all fitted with a range of monitoring equipment. The packaging area has several semi automated carton erectors and stuffers although ad hoc manual packing is not uncommon. During the initial fact finding visit manual processes were seen in operation in Preparation, Formulation, Fill & Finish and Packaging areas. The laboratory is situated at the far end of the factory as that was the only location where fumes could be extracted when the equipment was installed although the fume cupboards have been used very rarely in the last 2 years following complaints from the then Managing Director about fumes in his office. There is also a spacious reception area which was recently refurbished, laid with a marble floor and decorated with specially commissioned art. The area is 3 storeys's and has offices on the 2nd and 3rd floor for the directors and managers, other than manufacturing who have their offices by goods receiving, as well as other professional staff. Parking is available outside the main office block although this is restricted for senior office staff and visitors only; all other employees must use the parking facilities at the rear of the factory. Dr. Steve Hogarth (R&D Director, Director of Quality) Steve has a PhD in Medical Science and joined Theramed around 5 years ago from his post with the local University research department specifically at the request of the then Managing Director to bolster the scientific credentials of the business. Steve is one of the highest qualified members of the senior team but lacks real experience in managing people, budgets and delivering business goals, having an almost purely academic career, as a protg of Dr Liefman it was often suggested he would eventually become head of R&D. Initially Steve joined as a senior R&D scientist with the specific challenge of developing the next generation of products. He was rapidly promoted after Dr Liefman left the business to pursue other opportunities. While Steve has the title of Director his salary grading remains at the top of the Medical Scientist grade. Steve has felt for a number of years that he has not had sufficient resources to deliver on his challenges. On top of this, Steve was handed responsibility for the Quality role on a temporary basis after the last Quality Director left the business. This was nearly 3 years ago. Steve is responsible for the following measures; Yield Loss Rate Waste product Supplier quality Rework and reprocessing Customer defects In one incident, he recounts, controls for two of the digital scales in the preparation area were positioned above each other in between the two scales making it hard to distinguish which display was for which scale, when the product was subsequently dispensed it meant that the wrong quantity of ingredients went into batches causing two entire batches to be defective. Despite this, he says, it . . product orders for one or more of the 3 main product volumes from various global regions. The data shows the customer satisfaction with the order process on a 1 to 100 scale where 100 is good, this is reported online by the customer via an automated feedback process. The management expect a minimum 65 rating and think they have a problem. The call handling agent records on their screens whether they think the customer was satisfied with the call as a yeso result. A sample data set has been obtained which shows a number of calls received and the associated call length (seconds), order team, product volume, region, whether the call was placed on hold, dead air time (seconds), day, shift, and whether a supervisor was on duty. Some customers have individual contracts which set the price and delivery expectations for a set period of time while others make spot buys and have no guaranteed price or delivery. The management team have asked you specifically to analyze this data and provide them a way forward. Bill Bragg (Manufacturing Operations Director) Bill has been with the business "for ever" having been one of the first employees back when Therapeutic Products Limited was formed, he has been in his current role for over 2 years having been promoted up through Supervisor and Production manager roles. While he has a wealth of experience his academic credentials are lacking. He ha sometimes been described as "hard bitten. As he believes Manufacturing Operations is the core of the business he remains disaffected as he was not considered for the Managing Director role. Bill is responsible for the following KPI's Production schedule adherence Set up and changeover time Volume achievement Direct operator hours . . Organisation Theramed is a relatively small organisation with around 250 employees, managers and directors. The senior management team is relatively new and mostly recruited from within the industry, the previous Managing Director had a policy of recruiting "safe pairs of hands. The organisation is traditional with functional Directors reporting to the Managing Director, each of who have organised their departments along traditional lines. In Manufacturing Operations most of the middle management and supervisory staff have been with the organisation for a long time, many have in excess of 10 years service having started life with the organisation when it was Therapeutic Products Limited. Considering manufacturing, and in particular formulation, the heart of the business the previous Managing Director had a policy that middle management and supervisory positions for these crucial roles were recruited from within the business. Shop floor staff in manufacturing have generally long service although the business manages peaks and troughs in demand by recruiting temporary labour through a local agency. . . . . Each department has a notional headcount as shown on the attached organisational diagram and summarised by department below; Finance = 11 Human Resources = 3 Manufacturing Operations = 161 Sales & Marketing = 18 Technical = 28 Materials = 5 Human Resources Employees work a variety of shift patterns and hours. The factory works 24 hours a day, 7 days a week, 360 days a year. Manager grade and above are generally salaried and work a contracted 40 hour = a Preparation Formulation Filling & Finishing Packaging Warehouse & Distribution In goods receiving all raw materials, including packaging and labeling products, are received according to a schedule and are processed for inbound quality checking by the laboratory according to the quality inspection requirements. In addition to manufacturing, a small R&D facility is based on site as well as having access to and personnel within a small University Teaching Hospital nearby. Theramed rely on the laboratory for consistent high quality and regulatory compliance, it is the heart of the control system and the carries out goods in inspection, process audit sampling and finished goods sampling. In Preparation the raw materials are weighed and dispensed prior to formulation. The formulation department is the traditional core of the operations and the area which has historically received most management attention. The finishing department carries out final batch samples and quality checks prior to filling, sealing and capping the finished product bottles in 50ml, 100ml and 150ml volumes. The packaging department is responsible for final packaging into the individual product cardboard sleeves depending on size; they also insert the correct patient advisory leaflet into the package depending on factors such as language, geographic region etc. Finished product is packaged into a bulk cardboard liner which is then shrink-wrapped. When the product was introduced some years ago the 50ml and 100ml bottles were distributed in a security sealed plastic vacuum formed package, these markets are reluctant to change and a small volume is still packaged in this way. - - - -- - --- - 1) Cap Injection Moulder - Automated 1000 Ton press with automatic material feed One operator unloads machine - Cycle time: 48 seconds - Changeover time: 8 hours (good to good) - Machine reliability: 95% - Observed inventory: 5 days of completed caps 2) Bottle Injection Molder - Automated 500 Ton press with automatic material feed - One operator unloads machine - Cycle time: 40 seconds - Changeover time: 4 hours - Machine reliability: 95% - Observed inventory: 2 days of completed fans 3) Security Seal - Automated process with load and unload as part of cycle time - One operator loads and unloads machine - Cycle time: Operator = 5 seconds, Machine = 30 seconds - Changeover time: 10 minutes for fixture change - Machine reliability: 70% - Observed inventory: 3 days of completed motors 4) Final Assembly One - Manual process with 2 operators - Cycle time: 60 seconds - Changeover time: 5 minutes for fixture - Reliability: 100% - Observed inventory: 12 days of sub-assemblies 5) Final Assembly Two - Manual process with 2 operators - Cycle time: 30 seconds - Changeover time: 5 minutes for fixture - Reliability: 100% - Rework 20% - Observed inventory: 2 days finished goods inventory 6) Rework Area One part time operator 7) Shipping - Staging area for van transport to main site - - - . Late or partial deliveries Unplanned downtime Factory utilization "Success in this role, he says, is all down to keeping batch sizes high. Push material through and keep going at all costs. I have real problems some times with quality from the prep teams which Steve just can't seem to get to grips with and frankly raw material on time delivery is appalling to the point where I have to maintain temporary labour in order to flex up and down to cover missed deliveries." Bill designed The Theramed Way, a standard operating model, of which he is very proud. He has often complained that he has labour inflexibility, I can't move people about because they aren't allowed to work on different equipment without being cross trained and signed off by quality, I frequently bring this up with Amy but we have yet to crack the problem Bill has changed the factory layout and manufacturing structure little during his time stressing stability and why change a winning formula. The factory is laid out traditionally and is shown in the attached layout sketch. The equipment is a mixture of new and old machinery as well as manual processes, some of which have not advanced since they were installed. Some of the older equipment is difficult to source parts for; one machine type has the factory services manager sourcing spares from eBay. Goods receiving, Warehousing and dispatch are at one end of the factory adjacent to the main office areas to maximize utilization of staffing in these a areas. Preparation is next to the warehouse and comprises of a number of large automatic batch weighing equipment where active and inactive materials are batched up in preparation for formulation. is matching cap, bottle and security seal and packing them) Issues daily shipping schedule to shipping department Production Process Theramed's processes for this configuration involve a moulded cap, moulded bottle, and security seal are produced on feeder lines and stored at final assembly 1. Final assembly 1 uses a cap, bottle and security seal to build a bottle assembly, then aseptically cleans the assembly before delivering to Final assembly 2. Final 2 matches the specific bottle, cap and seal. The finished units are then stored in the fin ned goods warehouse and shipped to the main site on a daily basis. The plastic raw material for the moulders are transported from AB Raw Materials to the receiving warehouse once a week. The material is then transported from the receiving warehouse to the moulders on a daily basis. Final assembly materials such as cardboard tray and shrinkwrap are supplied on a daily basis from Outside Supply company. A rework area exists after Final 2 to rework and reclean bottle assemblies that do not pass a final inspection. Process Steps 1) Cap Injection Moulder Automated 1000 Ton press with automatic material feed One operator unloads machine - Cycle time: 48 seconds - Changeover time: 8 hours (good to good) - Machine reliability: 95% - Observed inventory: 5 days of completed caps 2) Bottle Injection Molder Automated 500 Ton press with automatic material feed One operator unloads machine - Cycle time: 40 seconds - Changeover time: 4 hours - Machine reliability: 95% Observed inventory: 2 days of completed fans 3) Security Seal - Automated process with load and unload as part of cycle time One operator loads and unloads machine Cycle time: Operator = 5 seconds, Machine = 30 seconds - Changeover time: 10 minutes for fixture change - - - Question Draw the fish bone diagram of this case study. Background Formed in 1996 Theramed Limited focuses efforts on drug research, development, and manufacture for the relatively common mental condition Attention Deficit Hyperactivity Disorder (ADHD). The company manufactures and distributes from a single site in Surrey, UK. Research is carried out on site and also at a nearby University Hospital. The company was formed through a partnership agreement by leading ADHD researcher, Dr Alex Liefman, of the Queens Medical Centre, Nottingham, and the then contract medicines manufacturer, Therapeutic Products Limited. Theramed supply a novel, pleasantly flavoured, liquid drug supplied in 50ml, 100ml and 150ml bottles. It is comparatively 25% more expensive than altern ve treatments. The drug is easy to administer to children, being taken like a cough medicine; however it is only a reliable treatment for around 50% of diagnosed cases. Theramed supplies approximately 20% of the medicines used to treat the disorder. Attention Deficit Hyperactivity Disorder (ADHD) ADHD is also known as hyperkinetic disorder (the official term in the UK) and attention deficit disorder (ADD). All of these names are used to describe the problems of children who are unable to concentrate and are overactive. ADHD may affect up to one in 20 school-age children and is at least four times more common in boys than girls. Children are usually diagnosed around age 7 with week from Monday to Friday, 9am to 5pm, overtime is not paid for these groups. All others are hourly paid and work a shift pattern that has them work a three shift pattern for 3 days on 4 off one week followed by 4 days on 3 off 4 the following week. Production workers work an average of 42 hours a week inclusive of some overtime; this is paid at x1.5 for the first 10 hours per week and x2 for any hours above that. Peaks and troughs in demand are made up by recruiting and laying off temporary staff from local ncies temporary staff rarely stay more than 2 or 3 weeks. Working conditions are typical for a pharmaceutical plant, the management takes great care to ensure cleanliness and the Preparation, Formulation and Fill & Finish areas are air conditioned, well lit and relatively quiet. The leadership team are pleased that they have been able to reduce the incidence of work related injury in 2008 to 4.2 cases per 100 full time equivalent employees, this is down from and average of 6.7 in 2006 2007. Management and staff grades receive paid sick leave, senior staff receive 25 days a year paid holiday. More junior staff and all shop floor workers receive 20 days paid holiday and are not eligible for paid sick leave until they have completed 10 years service. There is a formal bonus scheme however this has not paid out for several years, it is rumoured that some staff members have received informal bonuses and the practice of paying hourly paid workers for overtime that has not actually been worked is common in order to achieve flexibility. Directors participate in a profit sharing bonus scheme. Senior management actively discourages union membership although some of the shop floor workers are members of a variety of unions, some staff are members of the Management, Scientific and Financial Union (MSF). a psychological therapies. This move has been largely due to a lack of reliable drug treatments coupled with media coverage of the lack of effectiveness of existing drugs, the potential side effects of those drugs and the success being achieved with patients following a managed nonmedical treatment regime. Unless a completely reliable drug is found it is likely that overall levels of control of the disorder by drug therapy will fall by approximately 50%. Current Business Financial Position Theramed Limited is listed on the London stock exchange (LON: TMED). Following a stable few years the share price has declined steadily over the last 3 years and is now around half of its level 3 years ago. In a sound market their operating margins stand at 3%, less than half that of the competition and there is real concern about future business viability There is a belief that even with a reduction in the overall level of drugs prescribed for the condition the business is viable due to the novel manner in which the Theramed drug works. It is believed that it can increase market share, although of a much smaller market. A number of long term, ethical, institutional investors are seeking change and recently forced a change in a number of board members. The investors believe that to be viable short term operating profit needs to be around 6% on sales within 6 months growing to 10% within 12 months. Last month a new Managing Director was recruited with responsibility for restructuring the business and returning it to healthy profit and able to reposition itself in a restructured market. Manufacturing Process The manufacturing operations process is relatively simple; it is very similar to manufacture of a simple ibuprofen product and, including support services, consists of the following departments. Goods receiving Laboratory Preparation . . Departmental Reports & Leadership Comments Brian Adams (Managing Director) Brian has been with Theramed for around 8 weeks having replaced the previous Managing Director at the insistence of a number of large investors. He has a background in pharmaceutical operations. He reports his key challenges as; Delivering a step change in the performance of the business Improving cohesion in the senior management team Improving performance of the Supply Chain Improving overall business Morale Influencing patient usage Stiff competition facing similar challenges High active ingredient costs Large institutional investors looking for rapid business improvement The senior leadership is generally hands off says Brian, most of the Directors haven't been to the shop floor in the last 3 months, if not longer". Brian has serious doubts about the manufacturing operations capability and ability to implement the changes required, everything I ask for [improvement activity] seems to disappear into a black hole, and nothing ever seems to . get done. Brian also remarks that, our managers run the business on a day to day basis, in the ways that they are used to, there seems to be no real understanding of business goals and an ability to work towards them. When talking about customer focus Brian added, Apart from our sales group, our leadership has no real contact wit customers or end users unless they are forced into it. Brian has worked with consultants in the past but has little hands on experience of process improvement through Lean Sigma techniques. He knows he needs to support a change programme but has little real understanding of the depth and breadth of that scope. symptoms continuing through adolescence and into adulthood. Diagnosis in adulthood is rare. As yet the cause of ADHD is unknown and there are many suggested causes. Some research suggests that ADHD is caused by genetic differences in brain function as a result of dopamine levels. Some research also shows that differences in metabolism, lack of omega-3 fatty acids and protein deficiencies also have an impact on incidence of ADHD. Other research links ADHD to exposure to cigarettes, alcohol or drugs while in the womb as well as linking it to pre-school television viewing and stressful home environments. After diagnosis treatment plans typically include several components including stimulants such as Methylphenidate, Amphetamines, and dextroamphetamines. In the last few years, particularly in light of media reporting of medicine side effects in children, more emphasis has been placed on nonmedicinal therapies such as; improved diet (reduction of caffeine, food additives etc), managed home behaviour, managed school environment, Psychological and behavioural therapies The Market Medicines in the UK are prescribed on the basis of clinical need and the patient has little real choice of drug regime. The market is dominated by powerful manufacturers who are able to influence the opinions and prescribing habits of General Practitioners directly. The market is also influenced by patients whose needs change often, usually in response to media coverage of certain conditions, treatments or side effects. Over the last few years the focus has been to move away from control of the disorder through drug control to treatment based on a range of non medical behavioural and