Question: Butanol is produced at relatively low concentrations within a fermentation process. Following fermentation, butanol is purified through a series of distillation separations. Purified butanol (you

Butanol is produced at relatively low concentrations within a fermentation process. Following fermentation, butanol is purified through a series of distillation separations. Purified butanol (you may assume 100 % pure butanol for property values) flowing at 9,500 L/h exists in the final distillation column at 93 C. Prior to loading into rail cars, the butanol must be cooled to 26 C. You have cooling water from a near-by-river flowing at 3 C (coming from a melting glacier and always maintaining this temperature). As a possible alternative, you have available Freon-12 at -30 C. You must provide detailed specifications, strong reasoning, and if necessary, citations for your assumptions to design a heat exchanger that will be capable of performing the required cooling of butanol. Solve the following questions:

1. Use the process described above and assume you want to keep the exiting temperature of the cooling fluid at no more than 16 C: Water is used as the coolant.

b) How many numbers of tube passes and shell passes, and where the coolant will be placed, in the shell or in the tubes? Why?). Make a neat diagram of your proposed configuration.

c) Determine the required heat transfer area.

d) Determine the number and size of tubes (inside and outside diameter and lengths), configuration, spacing, and material (copper)of construction. Provide a rationale for your selection for the tube pattern proposed, the spacing, and the material you choose.

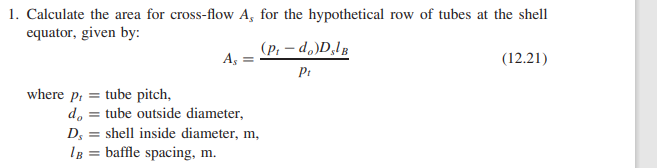

e) Determine the shell size, baffle spacing, and material of construction.

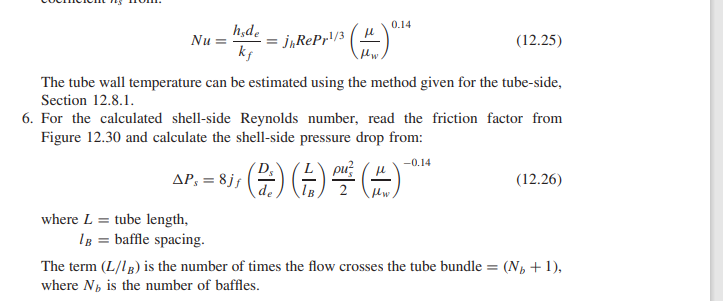

f) Determine the heat transfer coefficients and the percentage resistance values for all heat transfer resistances (do not neglect to foul).

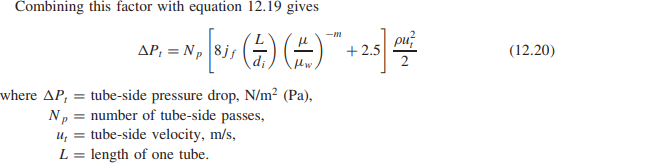

g) Determine the pressure drop on the shell side and tube side.

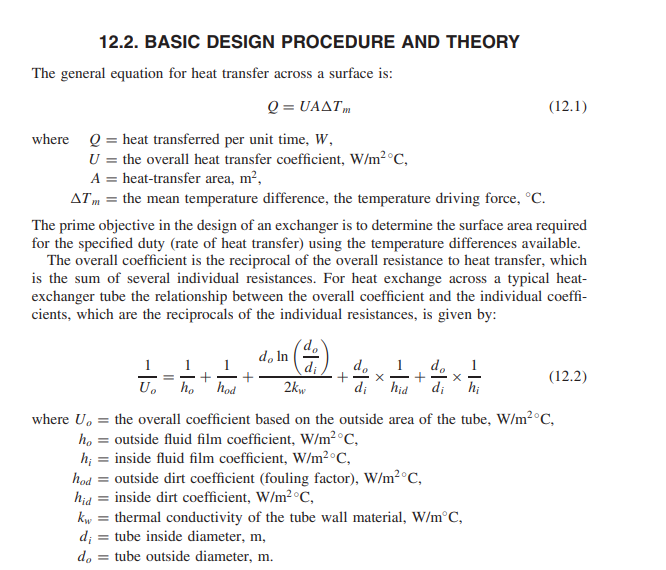

12.2. BASIC DESIGN PROCEDURE AND THEORY The general equation for heat transfer across a surface is: Q = UAATm where Q = heat transferred per unit time, W, U = the overall heat transfer coefficient, W/mC, A = heat-transfer area, m, (12.1) AT, = the mean temperature difference, the temperature driving force, C. The prime objective in the design of an exchanger is to determine the surface area required for the specified duty (rate of heat transfer) using the temperature differences available. The overall coefficient is the reciprocal of the overall resistance to heat transfer, which is the sum of several individual resistances. For heat exchange across a typical heat- exchanger tube the relationship between the overall coefficient and the individual coeffi- cients, which are the reciprocals of the individual resistances, is given by: where U, ho h; U = 'do' do In 1 di + do 1 d + ho hod 2kw di hid di hi (12.2) the overall coefficient based on the outside area of the tube, W/mC, outside fluid film coefficient, W/mC, inside fluid film coefficient, W/mC, hod = outside dirt coefficient (fouling factor), W/mC, hid = inside dirt coefficient, W/mC, kw = thermal conductivity of the tube wall material, W/mC, d; tube inside diameter, m, do = tube outside diameter, m.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts