Question: C ( 2 0 ) : A Flux - Cored Arc - Welding ( FCAW ) process is used to join two low - alloy

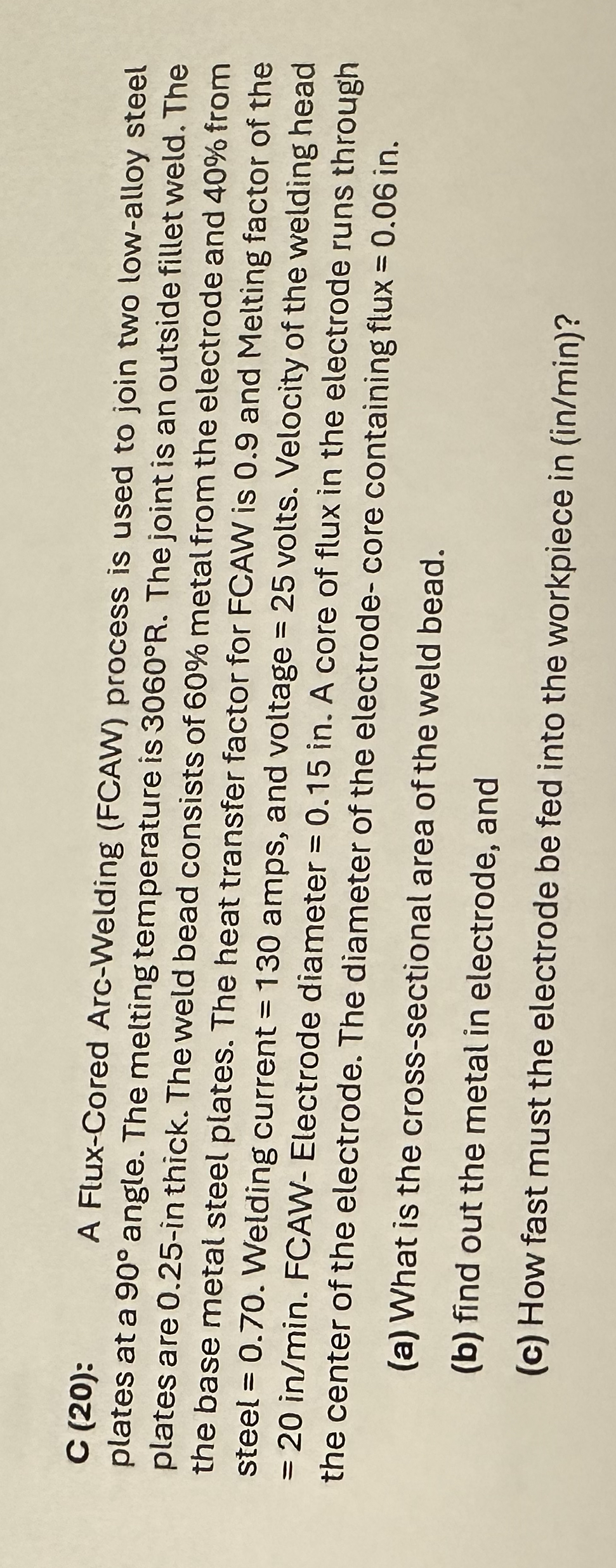

C: A FluxCored ArcWelding FCAW process is used to join two lowalloy steel plates at a angle. The melting temperature is The joint is an outside fillet weld. The plates are in thick. The weld bead consists of metal from the electrode and from the base metal steel plates. The heat transfer factor for FCAW is and Melting factor of the steel Welding current amps, and voltage volts. Velocity of the welding head FCAWElectrode diameter A core of flux in the electrode runs through the center of the electrode. The diameter of the electrodecore containing flux

a What is the crosssectional area of the weld bead.

b find out the metal in electrode, and

c How fast must the electrode be fed into the workpiece in inmin

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock