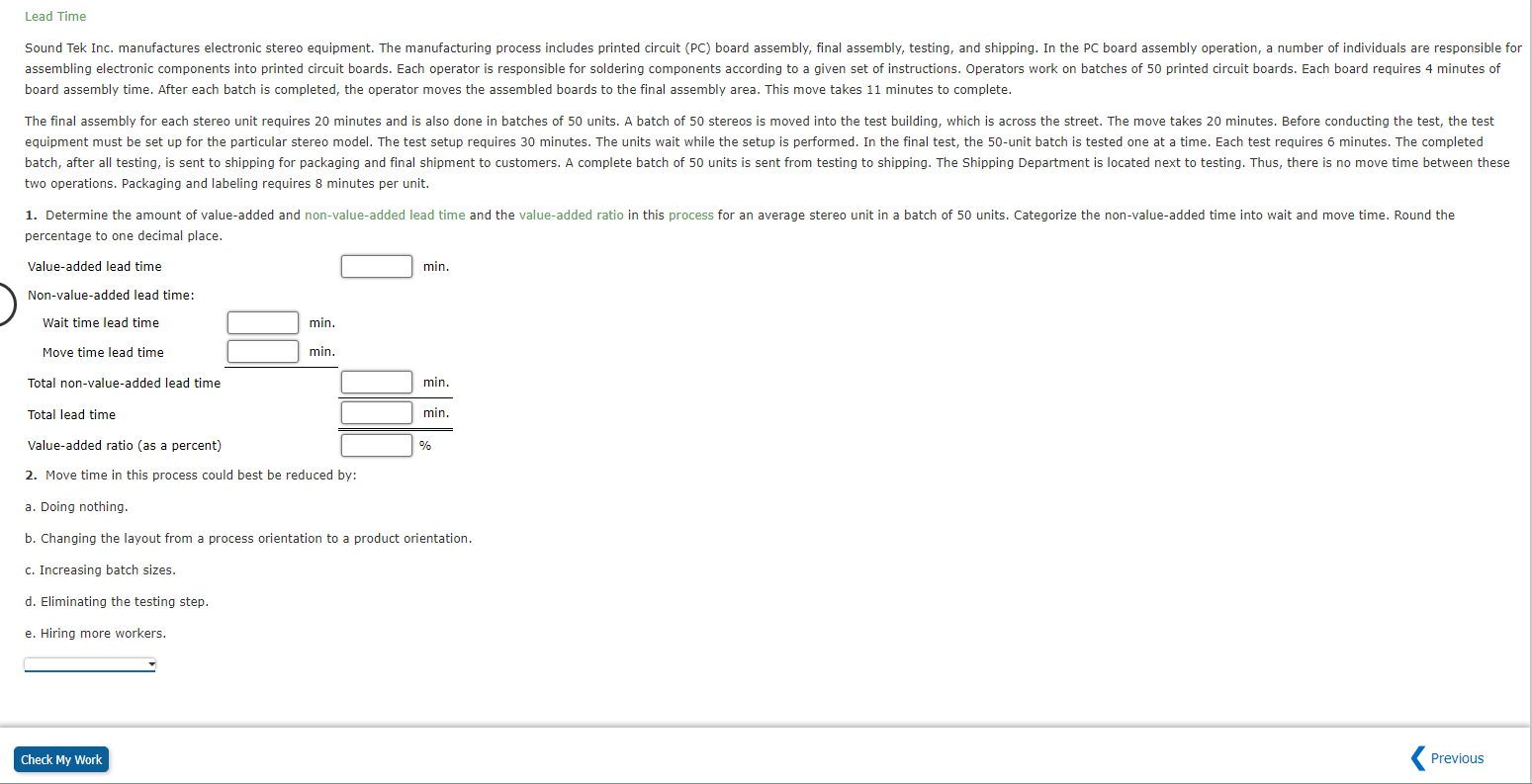

Question: Calculate Lead Timeboard assembly time. After each batch is completed, the operator moves the assembled boards to the final assembly area. This move takes 1

Calculate Lead Timeboard assembly time. After each batch is completed, the operator moves the assembled boards to the final assembly area. This move takes minutes to complete.

two operations. Packaging and labeling requires minutes per unit.

percentage to one decimal place.

Valueadded lead time

Nonvalueadded lead time:

Wait time lead time

min.

Move time lead time

min.

Move time lead time min.

Total nonvalueadded lead time

Total lead time

Valueadded ratio as a percent

Move time in this process could best be reduced by:

a Doing nothing.

b Changing the layout from a process orientation to a product orientation.

c Increasing batch sizes.

d Eliminating the testing step.

e Hiring more workers.

batch sizes of parts. A part requires minutes in milling and minutes in finishing. The move time between the two operations for a complete batch is minutes.

eliminated.

Traditional Philosophy Lean Manufacturing Philosophy

Valueadded time

min

min

Nonvalueadded time

min

min

Total lead time

min

min

Valueadded ratio as a percent

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock