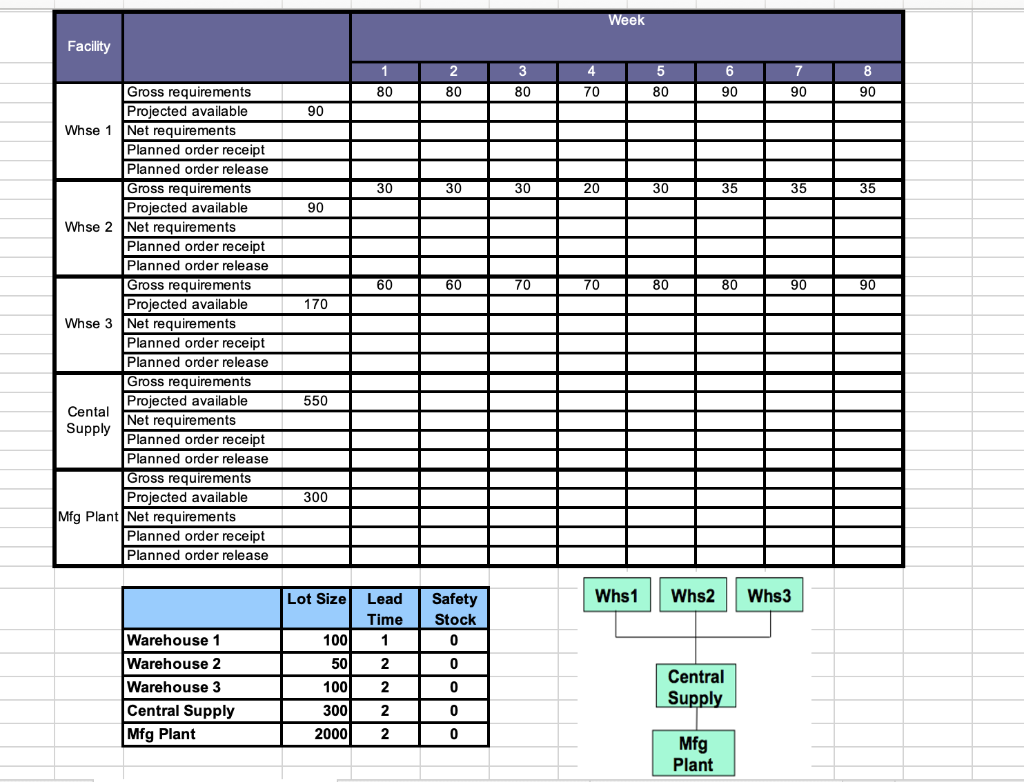

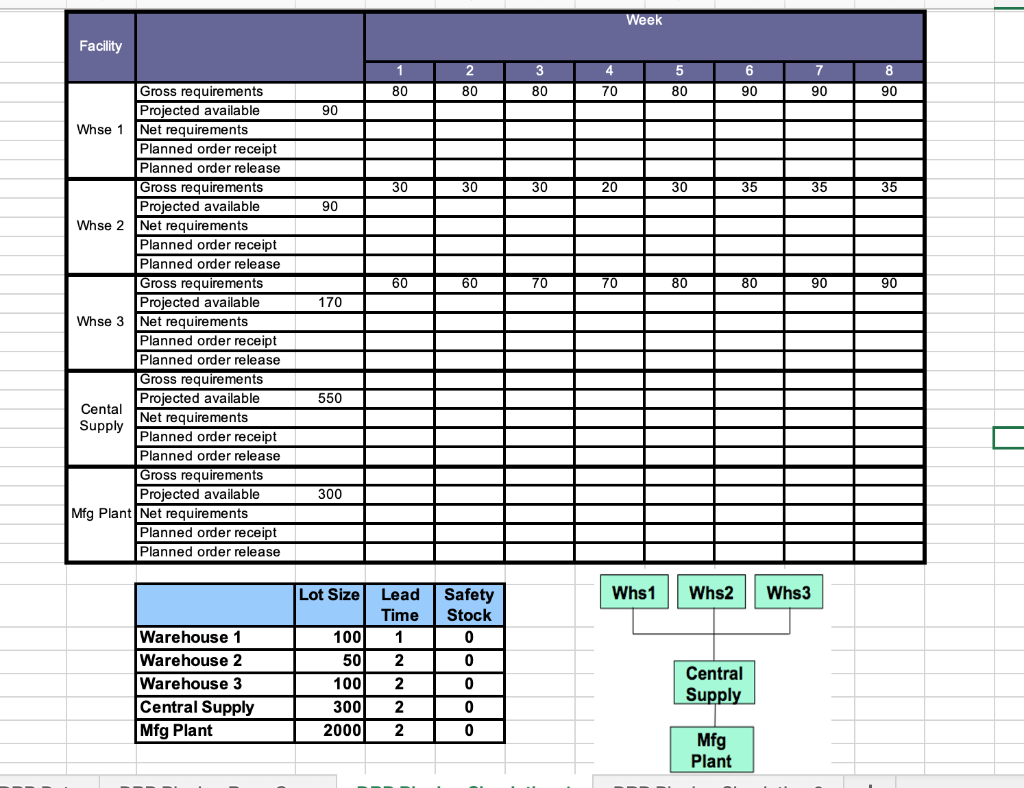

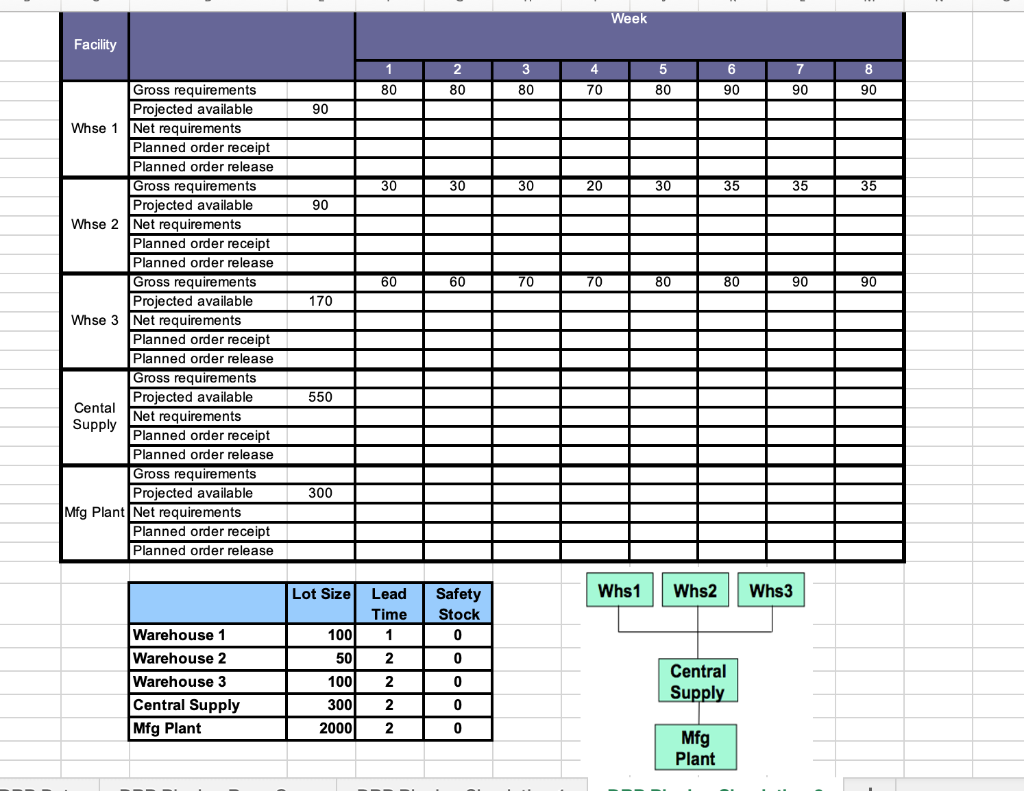

Question: Calculated the Distribution Requirements Plan fully document your approach and calculation methods on the Worksheet. 1. Compute the eight-week plan for the finished bike at

Calculated the Distribution Requirements Plan fully document your approach and calculation methods on the Worksheet.

1. Compute the eight-week plan for the finished bike at all Distribution / Local Warehouses and the Manufacturing Plant as well. Pay particular attention to key master data and the Bill of Distribution in completion of the Spreadsheet.

2. Consider some possible changes in Lot Size for different materials. Change any you think are appropriate and document the reason why on the Worksheet. Recompute the Distribution Requirements Plan based on these changes. Note: If you end up with Projected Available below 0 in any period you must adjust your Master Data.

3. Consider some possible changes in Safety Stock for different materials. Change any you think are appropriate and document the reason why on the Worksheet. Recompute the Distribution Requirements Plan based on these changes. Note: If you end up with Projected Available below Safety Stock in any period you must adjust your Master Data.

Leadership Recommendations

1. The advantages and disadvantages of Distribution Requirements Planning vs. other possible methods.

2. The advantages and disadvantages of moving to a Local Supply points for the Company.

3. Review the Master Data presented and consider concepts learned in other Modules particularly as related to order quantities, safety stock and such. Propose (and describe) some changes you might make and the reasons for suggesting the revisions. Create a new Worksheet / DRP Plan with your revised Master Data / assumptions reflected.

4. Based on the data and your analysis, what recommendations do you have for Management regarding the Distribution Requirements Planning Process and / or Planning Data configuration?

Week Facility 2 80 3 80 4 70 5 80 6 90 7 90 8 90 80 90 30 30 30 20 30 35 35 35 90 60 60 70 70 80 80 90 90 170 Gross requirements Projected available Whse 1 Net requirements Planned order receipt Planned order release Gross requirements Projected available Whse 2 Net requirements Planned order receipt Planned order release Gross requirements Projected available Whse 3 Net requirements Planned order receipt Planned order release Gross requirements Projected available Cental Net requirements Supply Planned order receipt Planned order release Gross requirements Projected available Mfg Plant Net requirements Planned order receipt Planned order release 550 300 Lot Size Whs 1 Whs2 Whs3 Lead Time 1 Safety Stock 0 100 2 0 Warehouse 1 Warehouse 2 Warehouse 3 Central Supply Mfg Plant 2 0 50 100 300 2000 Central Supply 2 0 2 0 Mfg Plant Week Facility 4 2 80 3 80 5 80 6 90 7 90 80 70 90 90 30 30 30 20 30 35 35 35 90 60 60 70 70 80 80 90 90 170 Gross requirements Projected available Whse 1 Net requirements Planned order receipt Planned order release Gross requirements Projected available Whse 2 Net requirements Planned order receipt Planned order release Gross requirements Projected available Whse 3 Net requirements Planned order receipt Planned order release Gross requirements Projected available Cental Net requirements Supply Planned order receipt Planned order release Gross requirements Projected available Mfg Plant Net requirements Planned order receipt Planned order release 550 300 Lot Size Whs1 Whs2 Whs3 Safety Stock 0 0 Warehouse 1 Warehouse 2 Warehouse 3 Central Supply Mfg Plant Lead Time 1 2 2 100 50 100 300 2000 0 0 Central Supply 2 2 0 Mfg Plant Week Facility 3 4 7 1 80 2 80 5 80 6 90 8 90 80 70 90 90 30 30 30 20 30 35 35 35 90 60 60 70 70 80 80 90 90 170 Gross requirements Projected available Whse 1 Net requirements Planned order receipt Planned order release Gross requirements Projected available Whse 2 Net requirements Planned order receipt Planned order release Gross requirements Projected available Whse 3 Net requirements Planned order receipt Planned order release Gross requirements Projected available Cental Supply Net requirements Planned order receipt Planned order release Gross requirements Projected available Mfg PlantNet requirements Planned order receipt Planned order release 550 300 Lot Size Whs1 Whs2 Whs3 Lead Time 1 Safety Stock 0 100 2 0 Warehouse 1 Warehouse 2 Warehouse 3 Central Supply Mfg Plant 2 0 50 100 3001 2000 Central Supply 2 0 2 0 Mfg PlantStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts