Question: can anyone please help me to solve this problem can anyone please help me to solve this problem using value steam mapping Ratchet 1. In-bound

can anyone please help me to solve this problem

can anyone please help me to solve this problem using value steam mapping

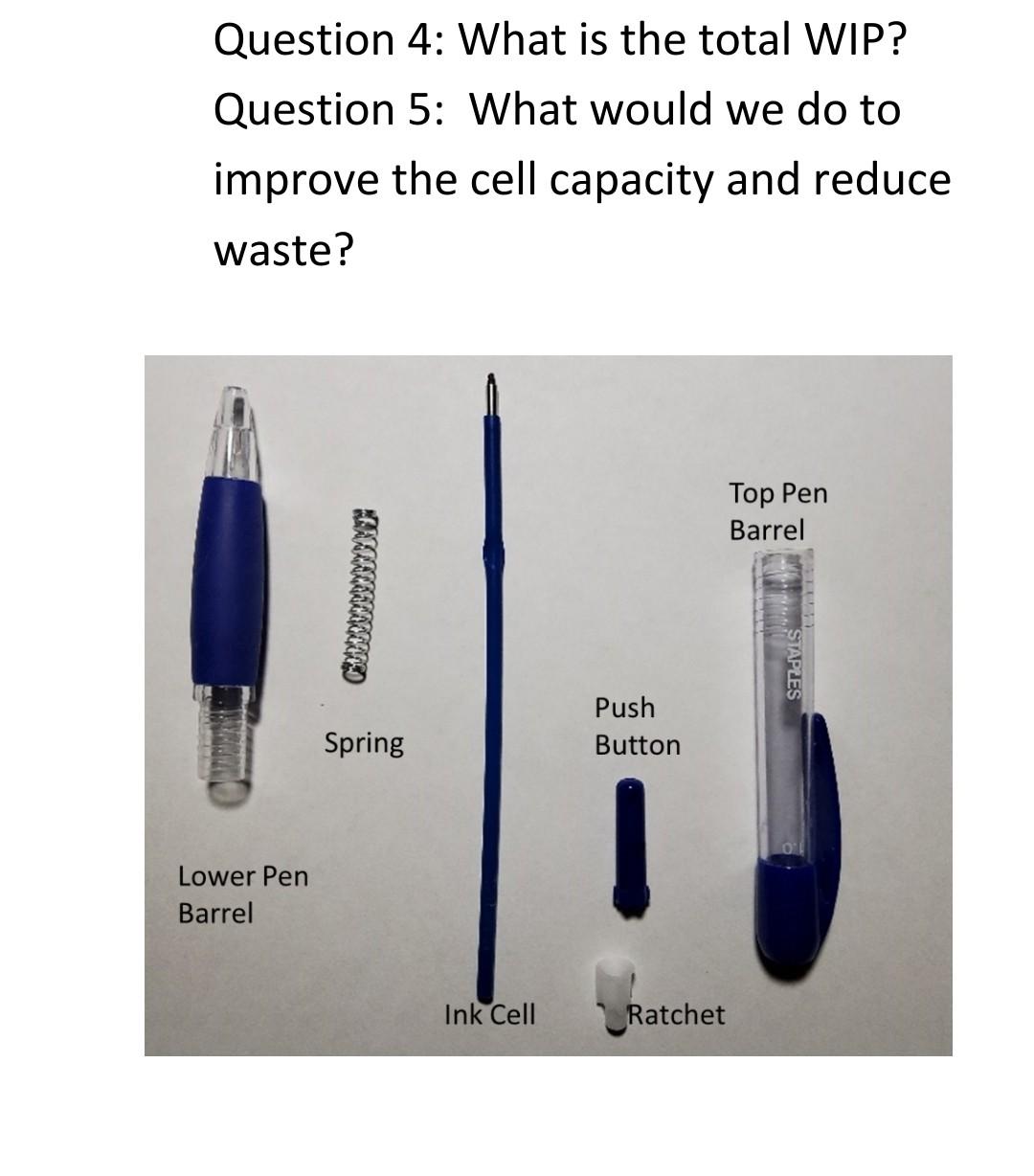

Ratchet 1. In-bound shipping: box of 500 2. Lead time: 3 days 3. Cycle Time: 3.5s 4. Yield: 75\%: 5. Change over time: 15 minutes 6. Change over loss: 12 Top Pen Barrel 1. In-bound shipping: box of 100 2. Lead time: 1 3. Cycle Time: 4s 4. Yield: 97\%: 5. Change over time: 5 minutes 6. Change over loss: 2 units Spring 1. In-bound shipping: box of 250 2. Lead time: 0.5 days 3. Cycle Time: 2.3s 4. Yield: 85\%: 5. Change over time: 15 minutes 6. Change over loss: 15 units Ink Cell 1. In-bound shipping: box of 1000 2. Lead time: 1 day 3. Cycle Time: 1.1s 4. Yield: 95\%: 5. Change over time: 20 minutes 6. Change over loss: 5 units Push Button 1. In-bound shipping: box of 250 2. Lead time: 0 3. Cycle Time: 2s 4. Yield: 90\%: 5. Change over time: 5 minutes 6. Change over loss: 2 See next pages for detail Pen Manufacturing - Working days per year: 250 - Working weeks per year: 50 - Hours per shift per day: 8 - Shifts per day: 1 - Cell reliability 85\% - Time for breaks and meals: 45 minutes - Pens per shipping container: 25 - Derating percentage: 87\% - Annual Demand: 250,000 blue pens - Annual Demand: 75,000 red pens Lower Pen Barrel 1. In-bound shipping: box of 100 2. Lead time: 2 days 3. Cycle Time: 1.3s 4. Yield: 100\%: 5. Change over time: 5 minutes 6. Change over loss: 0 units Question 4: What is the total WIP? Question 5: What would we do to improve the cell capacity and reduce waste? 1. Using the Staples ink pen as an example and the following data, please construct a Value Stream Map of the assembly process for the six components. You may need to develop/create some of the assembly time data using your pen. If you use cardboard or foam to model an assembly fixture, please illustrate your answer with pictures. Feel free to be creative. Please provide answers for the following questions: Question 1: What is the assembly cell capacity per day? Question 2. What is total Cycle Time (Process Time)? Question 3: What is the total Lead TimeStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts