Question: can someone help me please Parchase Negotiation Case: Buyers Package (Queen Corpl) Common information This sinulation irivchibs negotialing the burchaso of an auharthetive fabnc The

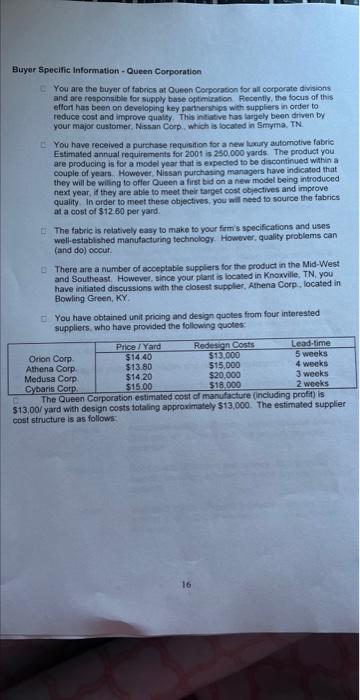

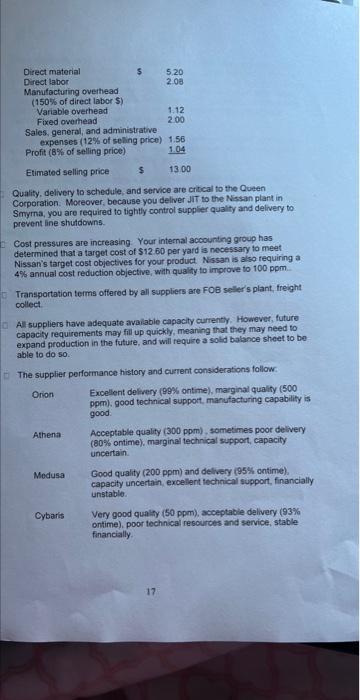

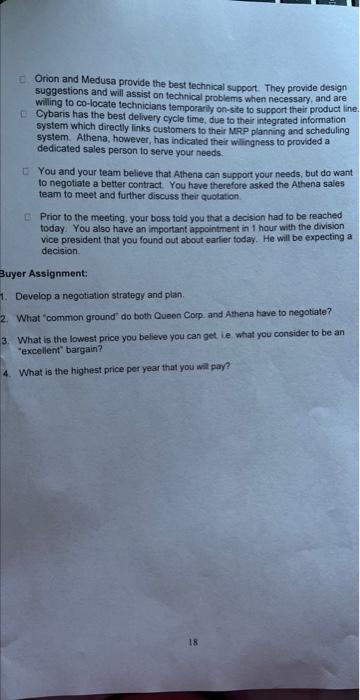

Parchase Negotiation Case: Buyers Package (Queen Corpl) Common information This sinulation irivchibs negotialing the burchaso of an auharthetive fabnc The following information a common is an groups participating in the negotiatien. There are four potential manulacturers ef textile products. These inciude the following. Ahena Corp: - Annual sales of approx. 340 mition dolars, located in Bowhing Green, Kontucky... Cybaris Corp. A Annual sales of approx. 550 milison dollars. Hocated in Chailotle, NC Medusa Corp. - Arnual sales of appror. 320 million dolars, located in Columbus, OH Orion Corp - Annual sales of approx 535 minis on dollars, located in Grand Rapids. MI. There are four potential purchasers of textile products. These companies are socond tier automotive suppliers who supply the major automotive companies located in Michigan, Ohio, and the Southeast. These companies takve air purchased in small quantities from an of the suppliers, and include the following: King Corporation, located in Greenvile, SC, has requirements for 150,000 yards of fabric for 2001 . The products will be required in 2002 and 2003 according to cutrent plans. and volumes are expectec to increase. Queen Corporation, located in Krncxville, TN, requires 250,000 yards of the fabric for 2001 , but volumes for 2002 and 2003 are uncertain Duke Corporation, located in Cleveland, OH, requires 100,000 yard of the product, and production volumes required are expected to increase by 50% or more in 2002 and 2003. Duchess Corporation, located in Lansing. M. requires 200,000 yart of the product, and volumes are expected to decrease somewhat in 2002 and 2003. Prices for similar fabrics are in the $12.00 to $15.50 price range per yard. All identified suppliers are able to produce to specifications provided by the purchasing company. However, quality performance related to the produc can vary greatly. Individual cost structures of the firms providing the fabrics can vary significantly. Suppliers provide widely different levels of service and technical support. All suppliets have to satisfy the same qualify and delivery terms.payment ferms, and transportation (FOE setier's plant'). Industry copacily ufiaation is abbut 75 percent. All purchasing companies have purchased relatively small amounts from all of the supplars previously, never totaling more than 5100.000 per purchase: Assignment: Students will work in mall groups and particpate in che tace to face negotiation session. Group size will not exceed 3.4 people for emer the buying or selling negotiating team. Each group will develop a brief written negoliating strategy prior to the negotiation which is to be handed in to the instructor, then conduct an actual negotiation session with an assigned buyet/supplier group from the class. (Nole that an agreoment may not always occur with an assigned group). Eventualiy. each pair of groups will develop jointly a wisten contract that documents the outcome of the negotiation process. The instructor has an information packet for the buyer and the sellee which provides additional information required to prepare for and conduct the negotiatioa. Buyors and sellers can share as litile or as much of the information with ench other as they desire during the actual negotation. Groups must prepare property before oonducting the negatiation. Each group's negotiation strategy should be developed pnior to the negotiating session all group members are to participate in the research planning as well as the actual negotiation. Remertiber, price is not the only variable subject to negctiation. Be creative when crafting your agreement. Buyer Specific Information - Queen Corporation You are the buyer of fabncs at Queen Corporation for all corporate divisions and are responsible for-supply base ogtimitation. Recently, the focus of this effort has been on developing key partherships with suppliers in order to reduce cost and improve quality. This intiative has laggely been diven by your major customer, Nissan Corp., which is focated in Smyma. TN. 4. You have received a purchase fequisition for a new hanary automiotive fabric Estimated annual requirements for 2001 is 250.000 yards. The product you are producing is for a model year that is eipected to be discontinued within a couple of years. However, Nissan purchating managers have indicated that they will be willing to offer Cueen a first bid on a new model being introduced next year, if they are able to meet their target cost objectives and inprove quality. In order to meet these objectives. you will need to source the fabrics at a cost of $12.60 per yard. The tahric is relatively easy to make to your firm's specificasions and uses well-establshed manutasturing technology. However, quality problems can (and do) occur. [ There are a number of acceptable suppliers for the product in the Mid-West and SDutheast. However, since your plant is located in Knowille, TN, you' have initiated discussions with the closest suppler, Athena Corp, located in Bowling Green, KY. - You have obtained unit pricing and design quotes from four interested suppliers, who have provided the following quotes: The Queen Corporation estimated cost of manuracrure punuunfu prumy na \$13.00/ yard with design costs fotaling approvimately $13,000. The estimated supplier cost structure is as follows: Qualify, delivery to schedule, and service are critical to the Queen Corporation: Moreover, because you delver JIT to the Nissan plant in Smyrna, you are required to tightly control suppler qualty and delivery to prevent line shutdowns. Cost pressures are increasing Your internal gcoounting group has determined that a target cost of $12.60 per yard is necessary to meet Nissan's target cost objectives for your product. Nissan is also requiring a 4% annual cost reduction objective, with quality to improve to 100ppm. Transportation terms offered by all suppiers are FOB seler's plant, freight collect. Al suppliers thave adequate twailable capacity currentiy. However, future capacify requirervents may fill up quickly, meaning that they may need to expand production in the future, and will require a sold balance sheet to beable to do 50 . The supplier performance history and curtent considerations follow: Erion Exollent delivery (99\%h ontime), marginal qualify (500 ppri). good technical support. manufacturing capability is good: Acchena - Actable quality (300 ppm) , sometimes poor delvery (80\% ontime), marginal technical support, capacity uncertain. Medusa Good quality (200 ppm) and delivery (95\%h cntime), capacity uncertain, excellent technical support, financially unstable. unstable. Cybaris Very good qualny (50ppm), acceptable delivery (93% ontime), poor technical rescurces and service, stable financially. svstem which directlu linkery cycle time, due to their integrated information system. Athena, however, has indisated their will planning and scheduling system. Athena, however, has indicated their willingness to provided a dedicated sales person to serve your needs. C. You and your team believe that Athena can support your needs, but do want to negotiate a better contract. You have therefore asked the Athena sales team to meet and further discuss their quotation. Prior to the meeting. your boss fold you that a decision had to be reached today. You also have an important appointment in 1 hour with the division vice president that you found out about earlier today. He will be expecting a decision. uyer Assignment: Develop a negotiation strategy and plan. What "common ground" do both Queen Corp. and Amena have to negotiate? What is the iowest pnce you believe you can get le what you consider to be an

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts